Shutdown and

Care

6.

Coil

the

hose and hang

It

on the hose rack when

storing it, even for overnight, to help protect the

hose from kinking, abrasion, coupling damage, etc.

To

reduce the risk of serious injury,

follow the illustrated Pressure

Relief

Procedure warning on page

12

when-

ever you are instructed to relieve pressure.

1.

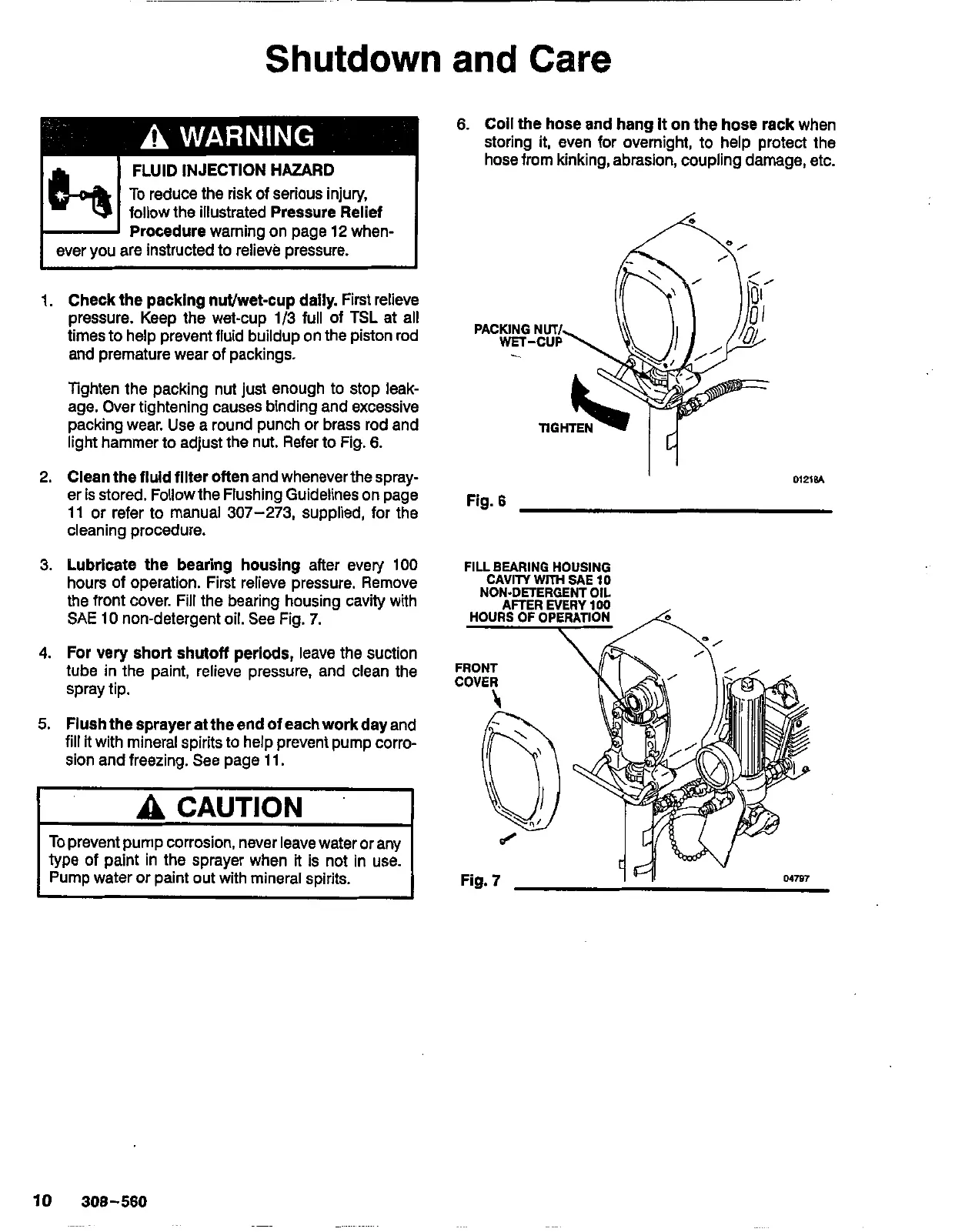

Check the packing nutlwet-cup daily. First relieve

times to help prevent fluid buildup on the piston rod

pressure. Keep the wet-cup

1/3

full of

TSL

at all

and premature wear

of

packings.

.

PACKING

NUT/

Tighten the packing nut just enough to stop leak-

age. Over tightening causes binding and excessive

packing wear.

Use

a round punch or brass rod and

light hammer to adjust the nut. Refer to Fig.

6.

2.

Clean the fluid fllter often and wheneverthe spray-

I'

er

is

stored. Follow the Flushing Guidelines on page

Fig.

cleaning procedure.

11

or refer to manual

307-273,

supplied, for the

01218*

3.

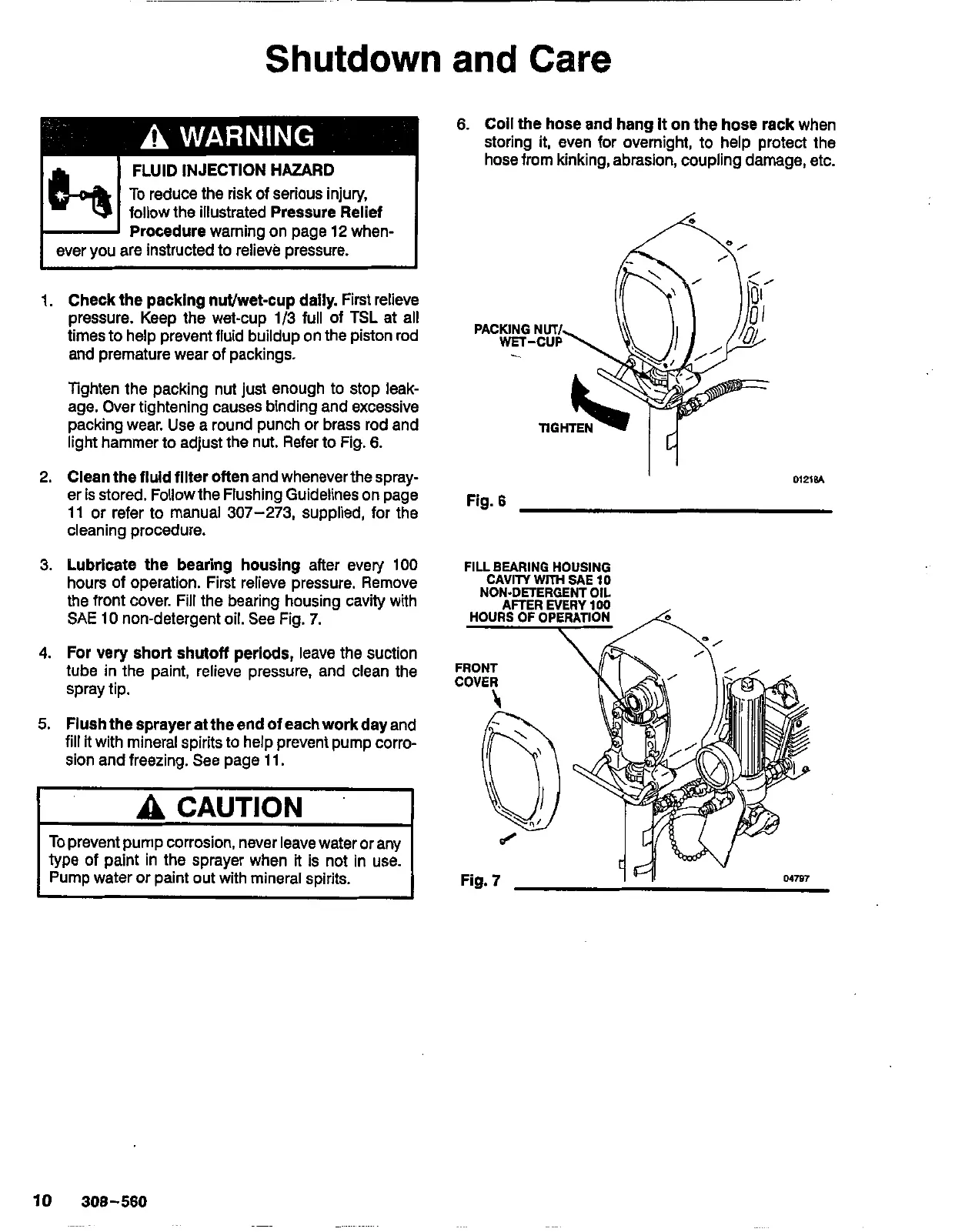

Lubricate the bearing housing after every

100

the front cover. Fill the bearing housing cavity with

hours of operation. First relieve pressure. Remove

SAE

10

non-detergent oil. See Fig.

7.

4.

For

very

short shutoff periods, leave the suction

tube in the paint, relieve pressure, and clean the

spray tip.

5.

Flush the sprayer at the end of each work day and

fill

it

with mineral spirits to help prevent pump corro-

sion and freezing. See page

11.

A

CAUTION

type of paint in the sprayer when

it

is

not in use.

To

prevent pump corrosion, never leave water or any

Pump water or paint out with mineral spirits.

Fig.

7

Loading...

Loading...