~

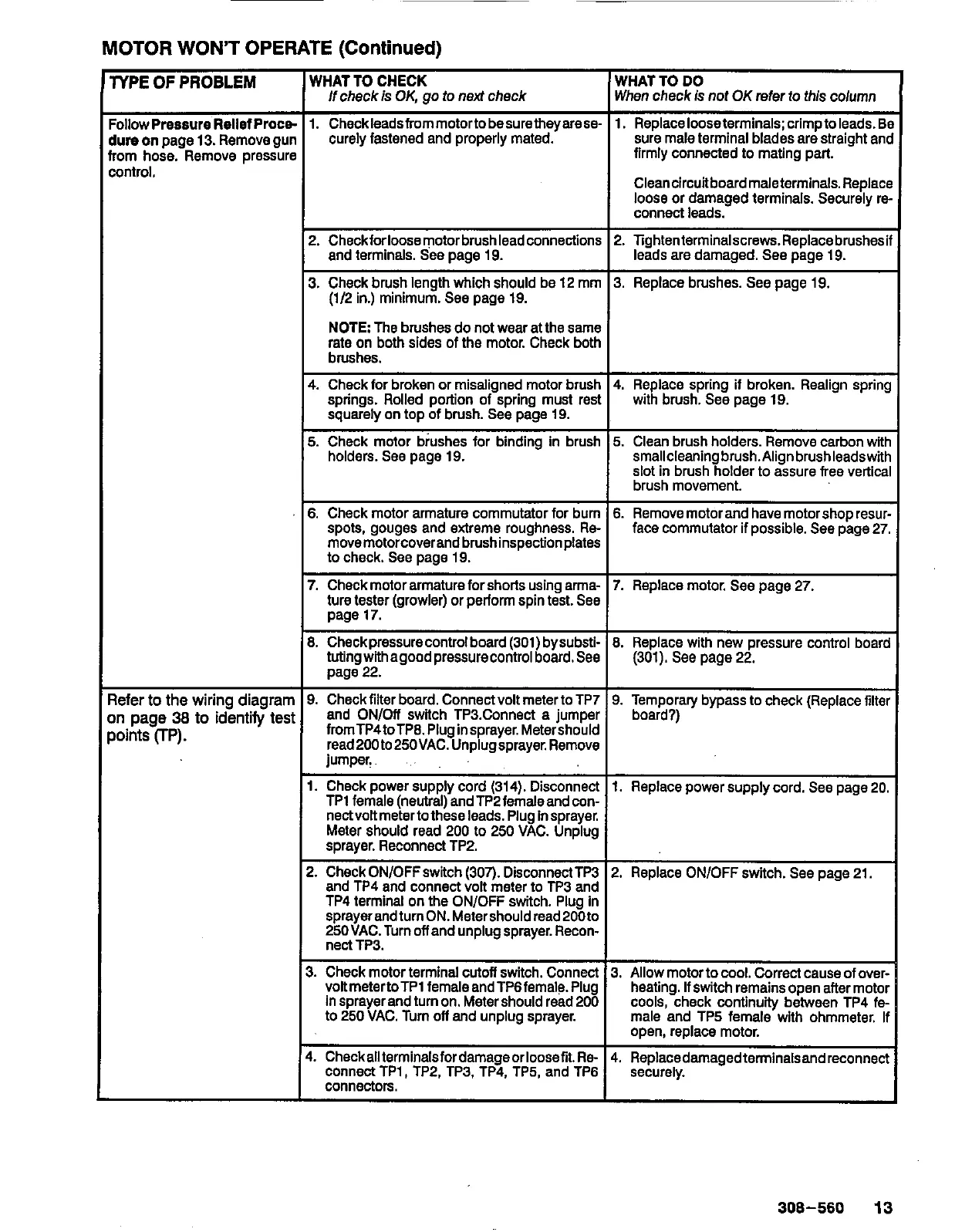

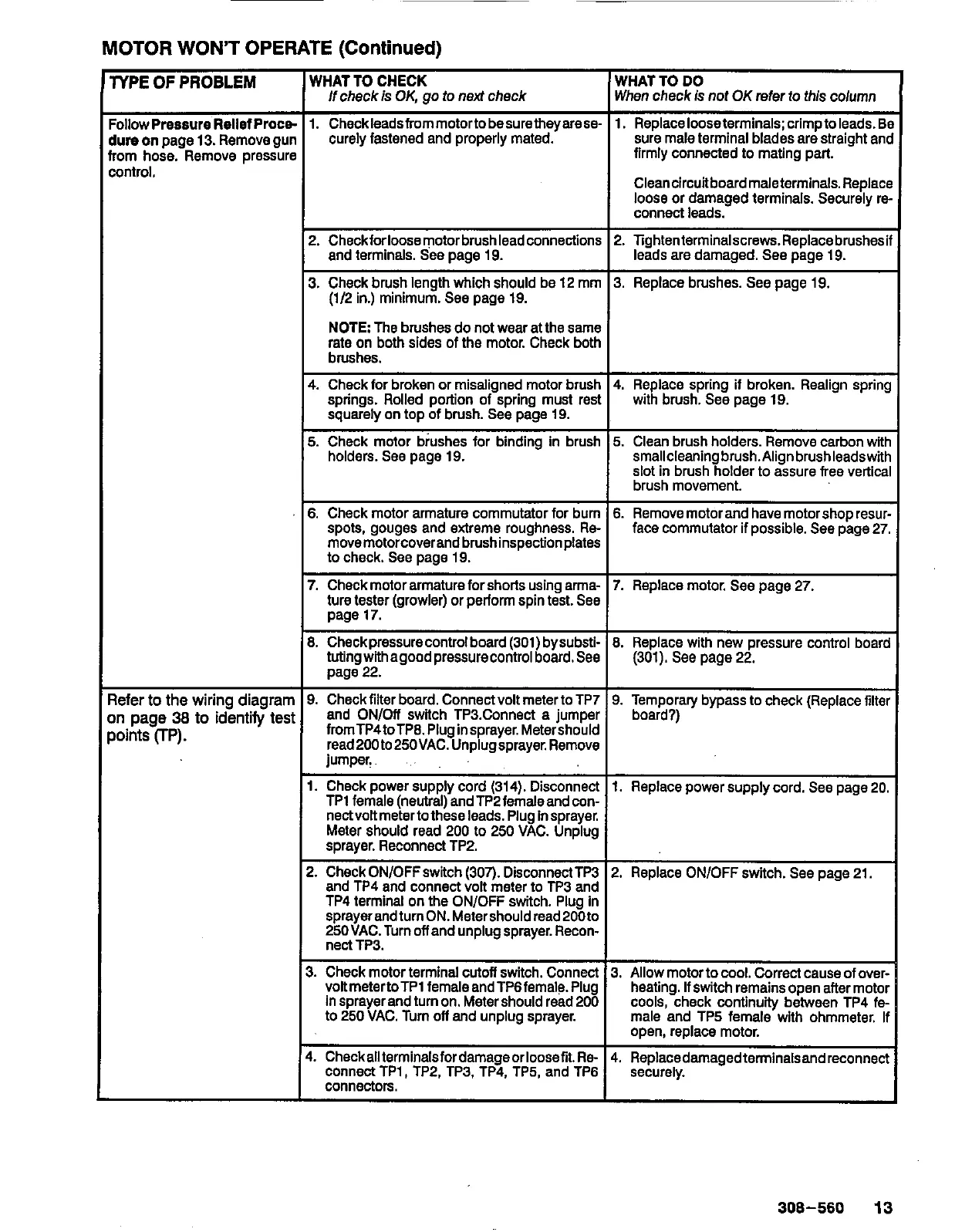

MOTOR

WON'T

OPERATE

(Continued)

YPE

OF

PROBLEM

Ollow

Pressure

Rellef

Proce

lure

on

page

13.

Remove gur

'om hose. Remove pressurf

ontrol.

lefer

to

the

wiring diagram

n

page

38

to

identify

tesi

oints

(TP).

WHAT TO CHECK

WHAT TO

DO

lfcheck

is

OK,

go

to

next

check When check is

not

OK

refer

to

this column

1.

Checkleadsfrommotortobesuretheyarese-

firmly connected

to

mating part.

sure male terminal blades are straight and

curely fastened and properly mated.

1.

Replacelooseterminals;crimptoleads.Be

Cleancircuitboardmaleterminals.Replace

loose

or damaged terminals. Securely re-

connect leads.

2.

Checkforloosemotorbrushleadconnections

3. Replace brushes. See page 19.

3. Check brush length which should be 12 mm

2.

lightenterminalscrews.Replacebrushesif

and terminals.

See

page 19.

(1/2 in.) minimum. See page 19.

leads are damaged. See page 19.

NOTE

The brushes do not wear at the same

rate on both sides of the motor. Check both

brushes.

4. Check for broken or misaligned motor brush

springs. Rolled portion of spring must re&

squarely on top of brush. See page 19.

5.

Check motor brushes for binding in brush

holders. See page 19.

6.

Check motor armature commutator for bum

spots, gouges and extreme roughness.

Re-

movemotorcoverandbrushinspectionplates

to

check.

See

page 19.

7.

Checkmotorarmatureforshorts using arma-

ture tester (growler) or perform spin test.

See

page 17.

8.

Checkpressurecontrolboard (301) bysubsti-

tutingwithagoodpressurecontrol

board.See

page

22.

9.

Check filter board. Connect volt meter to TP7

and ON/Off switch TP3.Connect a iumDer

fromTP4toTPB.Pluginsprayer.Mete&hchd

read200to250VAC.Unplugsprayer.Remove

jumper.

..

1.

Check power supply cord (314). Disconnect

TPt female (neutral) andTP2femaleandcon-

nectvolt metertothese leads. Plug Insprayer.

sprayer. Reconnect TP2.

Meter should read 200

to

250

VAC. Unplug

2.

CheckON/OFFswitch (307). DisconnectTP3

and TP4 and connect volt meter to TP3 and

TP4 terminal on the ONlOFF switch. Plug in

sprayerandturnON.Metershouldread200to

25OVAC. Turn

off

and unplug sprayer. Recon-

nect TP3.

~~ ~ ~~~~ ~~~

4.

Replace spring

if

broken. Realign spring

with brush. See page 19.

5.

Clean brush holders. Remove carbon with

smallcleaninabrush.Alianbrushleadswith

slot

in

brushholder to &sure free vertical

brush movement.

I

6.

Removemotorand have motorshop resur-

face commutator if possible. See page 27.

(301). See page

22.

9. Temporary bypass

to

check (Replace filter

board?)

3.

Check motor terminal

cutoff

switch. Connect

to

250

VAC. Turn

off

and unplug sprayer.

heating.

If

switch remains open after motor

voRmetertoTP1 femaleandTP6female. Plug

3. Allow motor

to

cool. Correct cause of over-

Insprayerand turnon. Metershould read200

cools, check continuity between TP4 fe-

male and TP5 female with ohmmeter.

If

open, replace motor.

4.

Checkallterminalsfordamageorloosefit.Re-

4.

Replacedamagedterminalsandreconnect

connect TP1, TP2. TP3. TP4, TP5, and TP6

securely.

connectors.

I

I

308-560

13

Loading...

Loading...