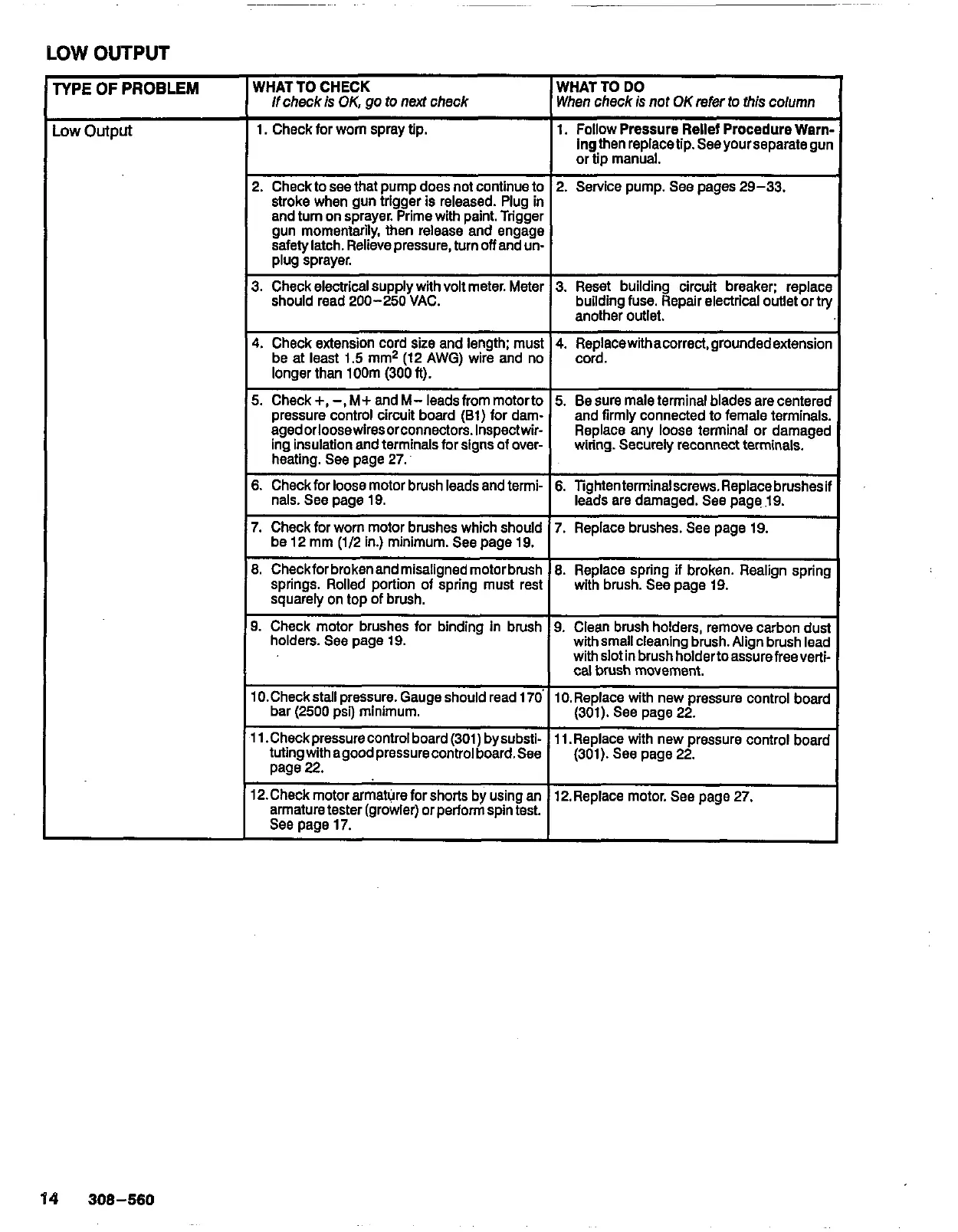

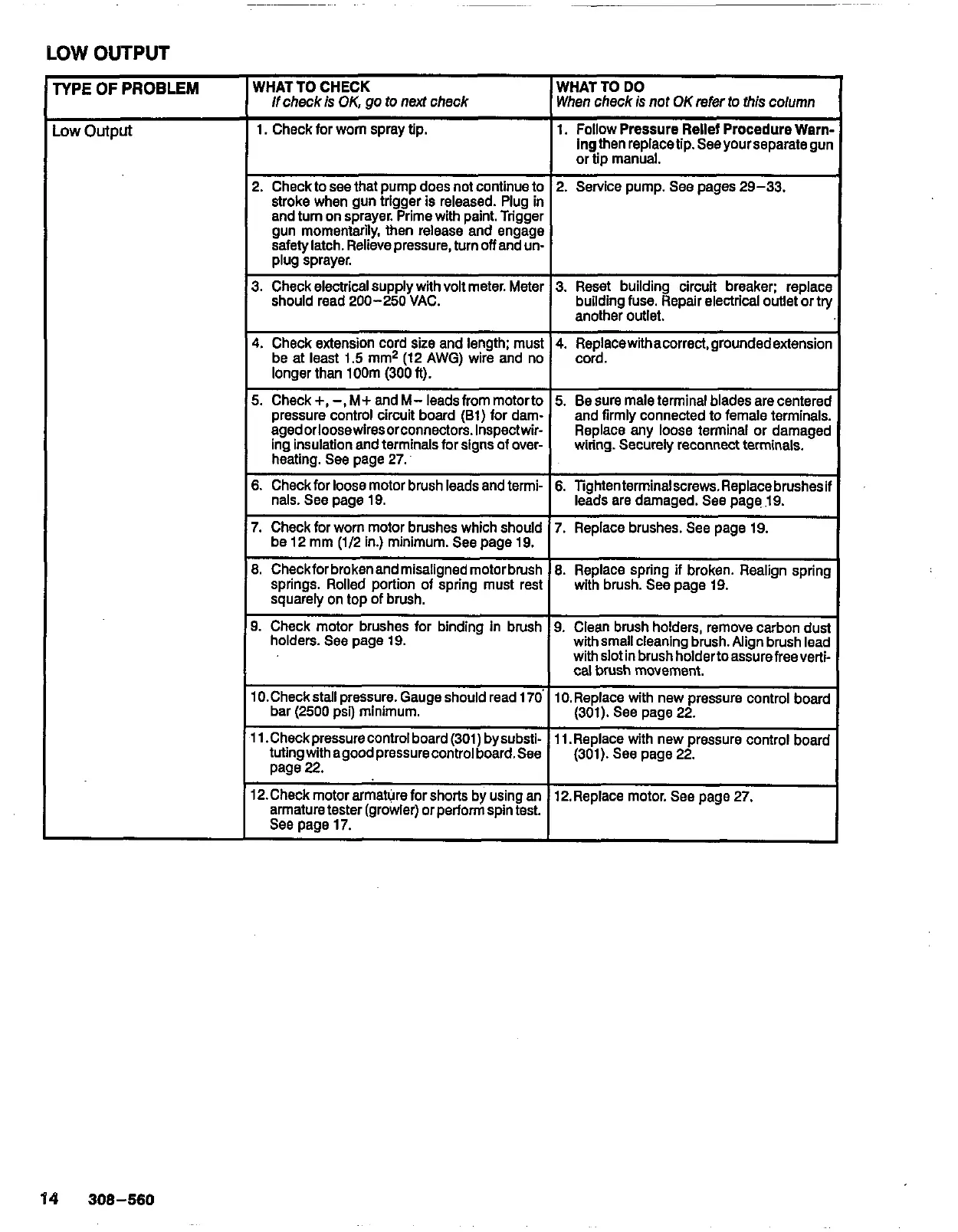

LOW

OUTPUT

WPE

OF

PROBLEM

.ow

output

WHATTO

CHECK

WHAT TO

DO

If

check

is

OK,

go

to

next

check

When check

is

not

OK

refer

to

?his

column

1.

Check for worn spray

tip.

1.

Follow Pressure

Rellef

Procedure Wern-

ing

then replacetip. See yourseparategun

I

or

tip

manual.

2. Check to see that pump does not continue

to

stroke when gun trigger is released. Plug

in

and turn on sprayer. Prime with paint. Trigger

safety latch. Relieve pressure, turn

off

and un-

gun momentarily, then release and engage

plug sprayer.

3.

Check electrical supply with

volt

meter. Meter

should read 200-250 VAC.

4.

Check extension cord size and length; must

be at least

1.5

mm2 (12 AWG) wire and no

longer than 100m (300

rt).

5.

Check

+,

-,

M+ and M- leadsfrom motorto

pressure control circuit board (61) for dam-

agedorloosewiresorconnectors.Inspectwir-

lng insulation and terminals for signs

of

over-

heating. See page 27.

2. Service pump. See pages 29-33.

3.

Reset building circuit breaker; replace

another outlet.

building fuse. Repair electrical outlet or

try

4.

Replacewithacorrect,groundedextension

cord.

5.

Be sure male terminal blades are centered

and firmly connected

to

female terminals.

wiring. Securely reconnect terminals.

Replace any loose terminal or damaged

6.

Checkfor loose motor brush leads and termi- 6

TigMenterminalscrews.Replacebrushesif

nals. See page 19.

I

'

leads are damaged. See page19.

I

7. Check for

worn

motor brushes which should

be 12 mm (1/2 in.) minimum. See page 19.

~~ ~~ ~~

7. Replace brushes. See page 19.

6.

Checkforbrokenandmisalignedmotorbrush

6.

Replace spring if broken. Realign spring

springs. Rolled portion of spring must rest

with brush. See page 19.

squarely on top of brush.

I

I

9.

Check motor brushes for binding in brush 9. Clean brush holders, remove carbon dust

holders. See page 19. with small cleaning brush. Align brush lead

with slot

in

brush

holdertoassurefreeverti-

cal

brush

movement.

10.Checkstall pressure. Gaugeshould read 170' 10 Replace with new pressure control board

bar (2500 psi) minimum.

I

'(301). See page 22.

I

11 .Checkpressurecontrol board (301) bysubsti-

11 .Replace with new pressure control board

tutingwithagoodpressurecontrolboard.See

page 22.

(301). See page 22.

12.Checkmotorarmatureforshort.s

by usingan 12.Replace motor. See pie

27.

armature tester (growler) or perform spin test.

I

1

See page 17.

..

I

Loading...

Loading...