Spray

312359R 41

Spray

NOTE: Ensure that the pump spray pressure regulator

is set to at least 35 psi (2.4 bar) for spraying.

NOTE: Ensure that the first gauge (supply) stays above

80 psi (0.55 MPs, 5.5 bar) while spraying.

After the first day of spraying follow Pressure Relief

Procedure, page 43, and then tighten throat seals on

both pumps and dosing valves.

1. If heaters are used, use Primary Heater Switches

(BC) on the heater junction box to turn them on. To

adjust heater temperature, refer to the Viscon HF

manual for instructions, and the Heat Fluid section,

page 40.

.

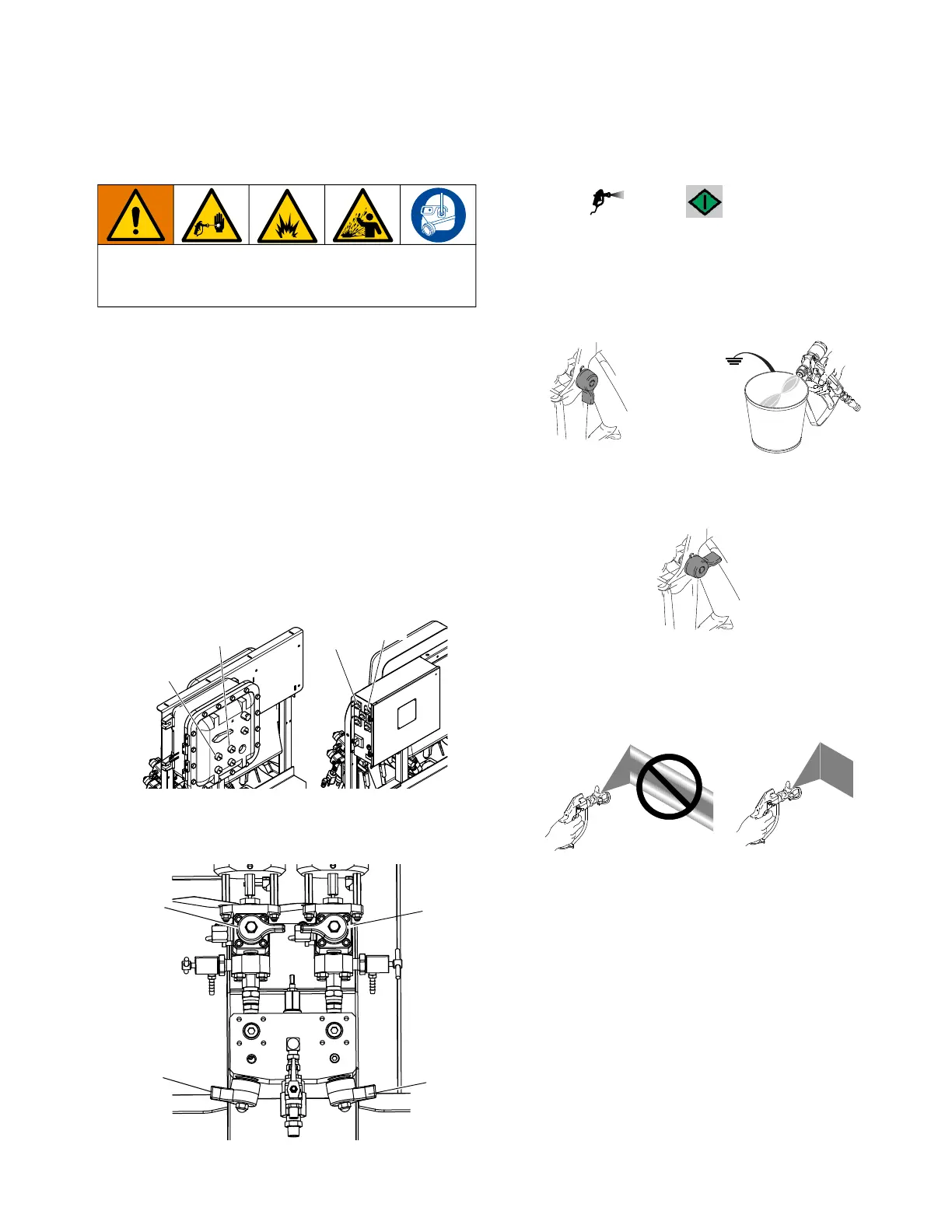

2. Close recirculation valves and mix manifold flush

valve. Open mix manifold valves A (blue) and B

(green).

.

3. Adjust pump air regulator to 30 psi (0.21 MPa, 2.1

bar).

4. Select . Press .

5. Disengage trigger lock and trigger gun into a

grounded metal pail. Use a metal pail lid with a hole

to dispense through to avoid splashing. Dispense

flush solvent out of mix hose until a well mixed

coating flows from the gun.

6. Engage trigger lock. Install tip on gun.

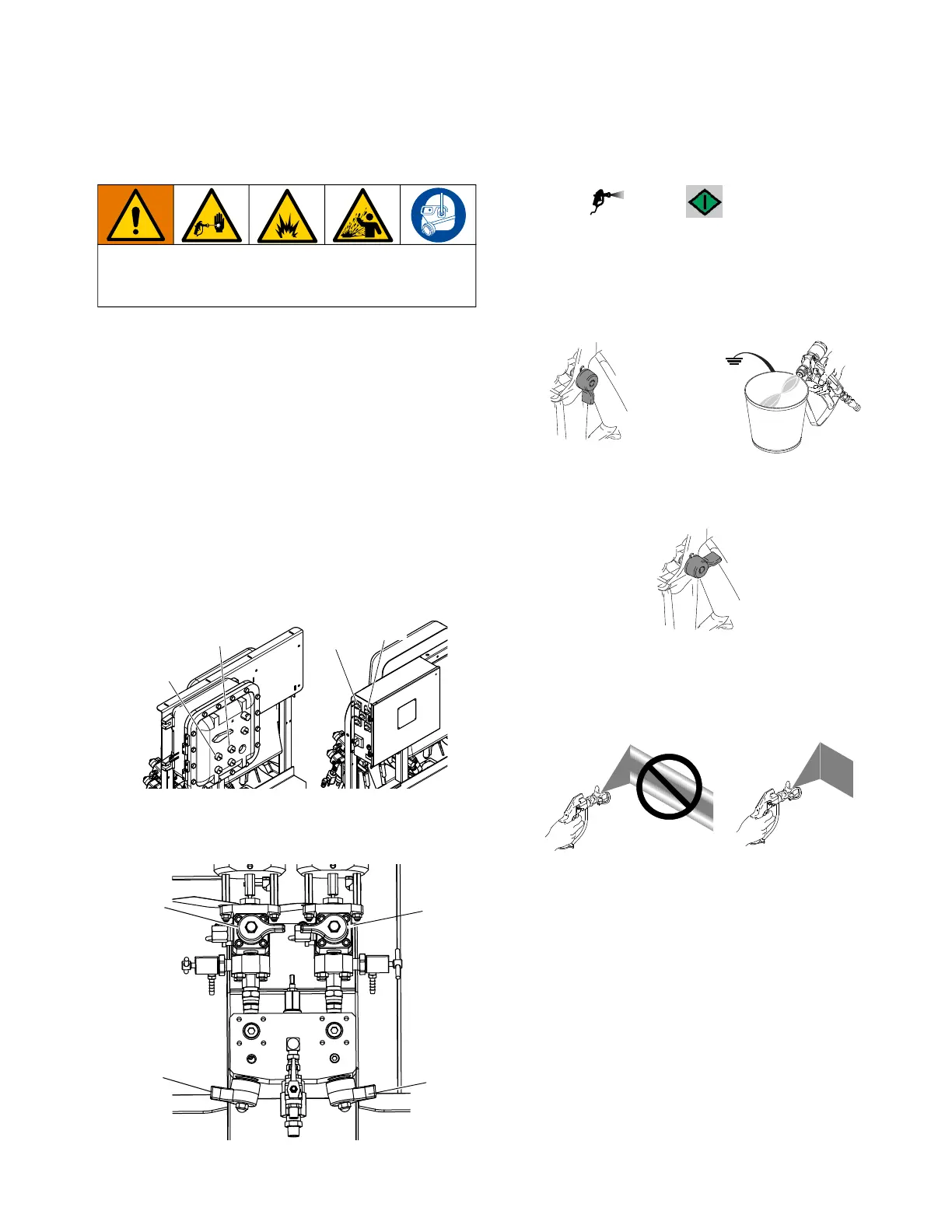

7. Adjust air regulator (CD) to the necessary spraying

pressure and apply coating to a test panel. Look at

ratio screen to ensure it is reading the correct ratio.

Also, look at bar graph to ensure mix manifold

restriction adjustment is within optimal range. Refer

to Batch Dispense or Ratio Test, page 54 and

Adjust B Machine Outlet Restriction, page 42.

8. Follow Flush Mixed Manifold, Hose, and Spray

Gun, page 44, or Park Fluid Pump Rods, page 50,

when you are finished spraying or before potlife

expires.

NOTE: Mixed material potlife or working time

decreases with increased temperature. Pot life in

hose is much shorter than dry time of coating.

To help prevent injury from solvents and heated fluids,

wear gloves when using solvents and/or if fluid

temperature exceeds 110° F (43° C).

Hardener

Circulate

Resin

Circulate

Resin

Valve

(Blue)

Hardener

Valve

(Green)

TI1950a

TI1953a

TI1949a

Loading...

Loading...