What to do if metering pumps do not run when Run Mode is selected and the blue LED is illuminated on my Graco XM PFP?

- BBrenda MillerDec 1, 2025

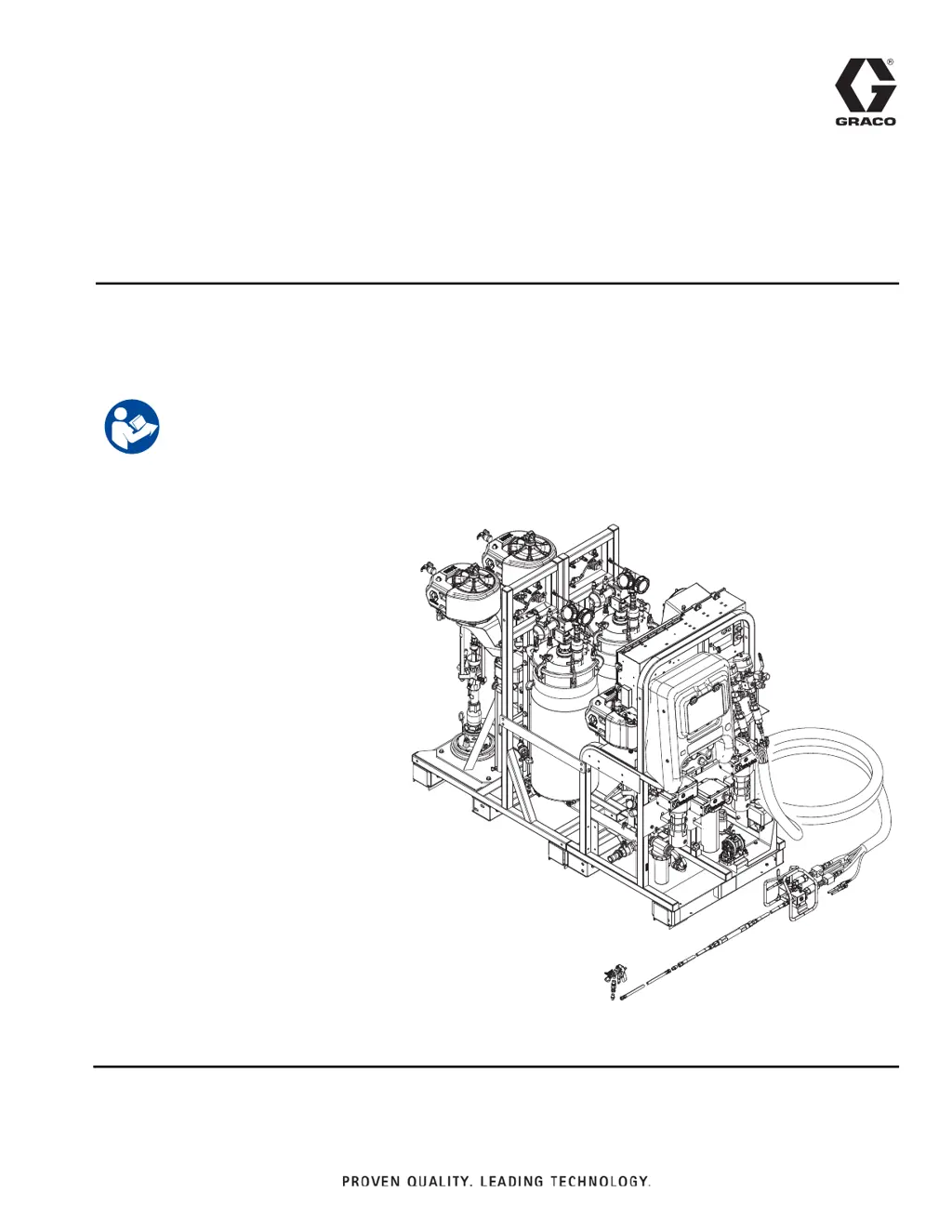

If the metering pumps on your Graco Paint Sprayer fail to run when Run Mode is selected and the blue LED is lit, consider the following: * Air pressure to metering pumps is too low. Increase the pressure to 50 psi (0.35 MPa, 3.5 bar) or greater. * Air pressure to metering valves is too low. Check the air regulator behind the main air panel; it should be at 80-85 psi (0.55-0.59 MPa, 5.5-5.9 bar). * Circulation valves or mix manifold ball valves are not open. Open the ball valves. * Air pilot lines are obstructed. Check the pilot lines for kinks or pinches. * Solenoid valve stuck. Actuate solenoid manually, if it does not operate, replace solenoid. * Air pilot valve(s) to motor stuck. Replace valve(s). * Metering valve(s) not opening. Service or replace valve(s). * Air motor...