Page 58

A1.1 WILO YONOS PARA RS RKC

CIRCULATING PUMP

A1.1.1 PUMP SPECIFICATION

Table A1-1: Pump specication

Make and model

Wilo Yonos PARA RS 15/7.0 RKC

FS 130 12

Construction

Pump housing

Cast iron (with cataphorisis treat-

ment)

Impellar PP composite with GF 40%

Pump shaft Stainless Steel

Bearing Carbon, metal impregnated

Protection Class IPx4D

Insulation Class F

Motor Protection Integrated

Performance

Max. delivery head 7.2m @ Q = 0 m

3

/h

Max. volume ow 3.3 0 m

3

/h

Minimum suction head @ 50/95°C 0.5/4.5m

Power consumption @ 1 - 230V 3-45W

Nominal Motor Power 37W

Current @ 1 - 230V 0.028 - 0.44 A

Energy Eciency Index (EEI) ≤ 0.20

Speed 800-4650 rpm

Settings

∆P-variable (1-7m head) and Con-

stant Speed (I, II and III)

Application

Maximum Static Pressure PN6

Temperature range @ maximum

ambient temperatures

Maximum ambient temperature

57°C: 0 to 95°C

Maximum ambient temperature

59°C: 0 to 90°C

Maximum ambient temperature

67°C: 0 to 70°C

Approved Fluids

Heating Water

Water/Glycol - Max 1:1 (above 20%

check pumping data)

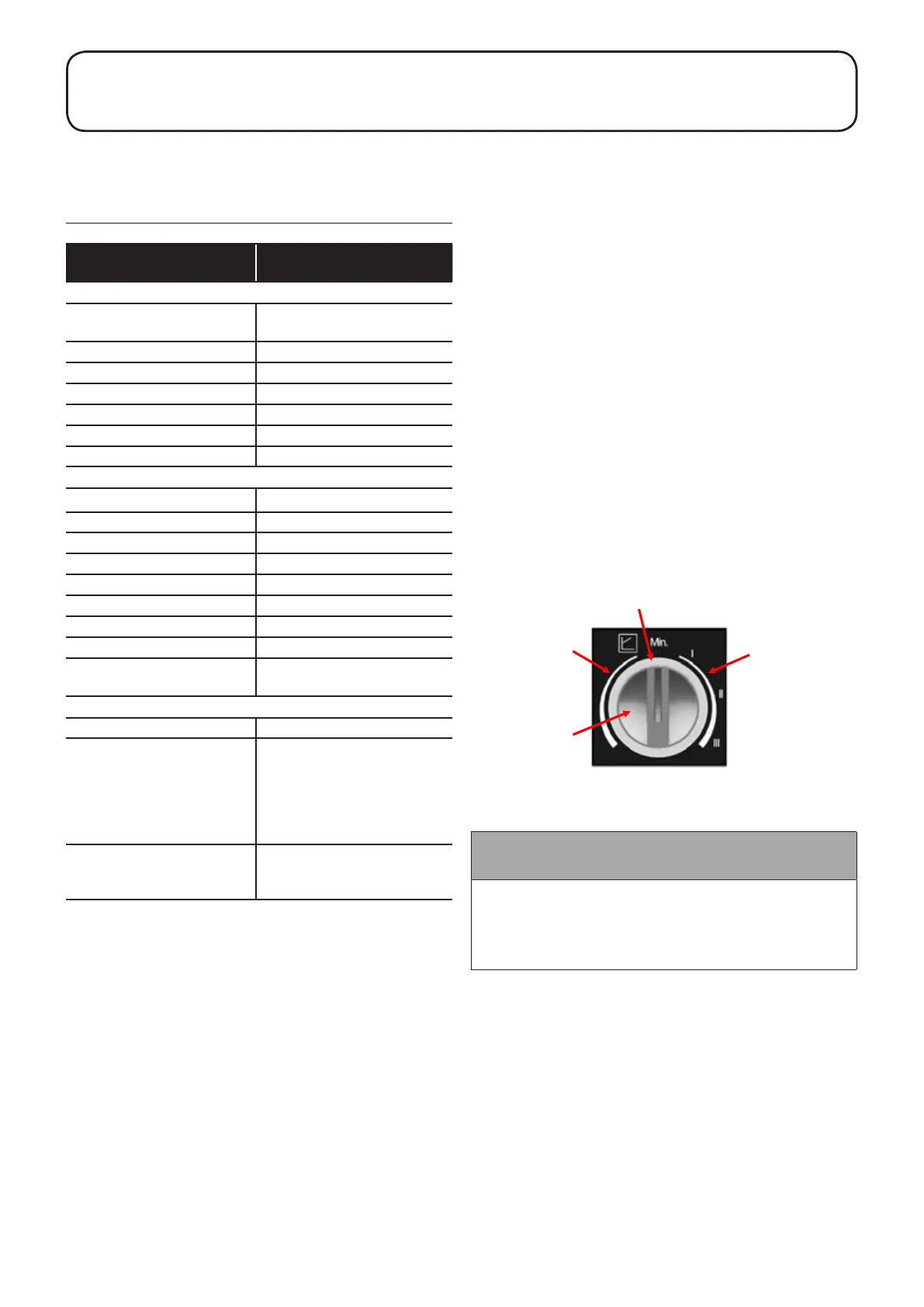

A1.1.2 PUMP CONTROL PANEL

Wilo Yonos PARA RKC circulating pumps have two possible

setting modes:

• Constant speed with three pump speed settings (I, II and III)

• Variable pressure (∆p-v) with pump head adjustable between

1 and 7m head

Figure A1-1 shows the pump control panel with the red selector

knob.

Constant Speed Mode (I, II, III)

This is the default setting of the pump and as such is

recommended by Grant for heating systems. In this mode the

pump speed is not automatically regulated (as with the Variable

Pressure Mode), but operates constantly at one of the three

possible speeds (set using the red selector knob on the pump

control panel).

Variable Pressure Mode (∆p-v)

In this mode the electronic control changes the dierential

pressure setpoint to be maintained by the pump in a linear fashion

between Hs (the value set using the red selector knob on the

pump control panel) and ½ Hs. The dierential setpoint varies

linearly with the volume ow Q.

A1.1.3 INDICATOR LED

The pump is tted with an indicator LED. This is located around

the circumference of the red selector knob. See Figure A1-1

below. This indicates the operating status of the pump and will

be illuminated green when the pump is operating normally. This

indicator LED can assist in diagnosing and rectifying faults. Refer

to Section A1.2.

A1.1.4 SETTING THE PUMP CONTROL MODE

Set the pump to one of the two operating modes as follows:

Constant Speed Mode (I, II, III)

Grant recommends this operating mode for the pump.

To set the pump to the ‘Constant Speed’ mode, the pointer on the

red selector knob must be set to the RIGHT of the mid position.

Refer to Figure A1-1.

Set it to point at the required speed setting, I, II or III as required,

ensuring that there is adequate ow to distribute the heat from the

boiler whilst avoiding high water velocities causing noise in the

pipework.

Variable Pressure Mode (∆p-v)

To set the pump to the ‘Variable Pressure’ mode the pointer on

the red selector knob must be set to the LEFT of the mid position.

Refer to Figure A1-1.

The further anticlockwise it is set the greater the pressure head

setting of the pump – from 1m to 7m head.

If this mode is to be used, set the selector knob at a pressure that

represents the maximum pressure (head) loss for the heating

system in question.

Variable Pressure Mode

settings: 1 to 7m head

Indicator LED

Constant Speed Mode

settings: I, II, III

Red selector knob

Figure A1-1: Pump control panel with red selector knob and LED

indicator

APPENDIX A1 WILO YONOS PARA RS RKC

CIRCULATING PUMP

Appendix A1: Wilo Yonos PARA RS RKC

! NOTE !

Both circulating pumps on all Grant Vortex Combi boilers

come factory set at Constant Speed Mode III and should be

left set on this setting.

The heating circuit circulating pump should be set by the

installer to suit the system.

Loading...

Loading...