GB - 32

Using Proper Fuel

Use regular grade unleaded fuel with an

octane rating of 87 octane or higher. Fuel

blends containing up to 10% ethanol or up to

15% MTBE reformulated fuel are acceptable.

Do not use fuel or additives containing

methanol as engine damage can occur.

Always use fresh, clean fuel that is purchased

in a quantity that can be used within

approximately 30 days, or add fuel stabilizer.

Fuel is blended to give best seasonal

performance. To avoid engine performance

problems such as hard starting or vapor lock,

use in-season fuel. Use fuel during warm

weather that was purchased during that

season, and use fuel during cold weather that

was purchased during that season.

Fuel can become stale in units with engines

that are used seasonally or infrequently

during a season. Stale fuel can produce

varnish and plug carburetor components

which can affect engine performance.

Keep fuel storage container tightly covered

and in a cool area out of direct sunlight. Fuel

can break down and degrade if not sealed

properly or exposed to sun and heat.

Condensation may collect in the fuel tank

because of a variety of operating or

environmental conditions and, over time, may

affect your unit’s operation. Fill fuel tank at

the end of daily use and store fuel in plastic

containers to reduce condensation.

For best year-round performance and fuel-

handling, add stabilizer to fuel immediately

after fuel purchase. This practice helps

prevent engine performance problems and

allows fuel storage in the unit all year without

draining.

To add fuel to the fuel tank:

1. Put the unit in an open area.

2. Stop the engine.

3. Allow engine to cool.

4. Clean the fuel cap and the area around

the fuel cap to prevent dirt from entering

the fuel tank.

5. Remove the cap from the fuel tank.

6. Fill the fuel tank. Be careful not to spill.

7. Install the cap on the fuel tank and

tighten.

8. Clean up any spilled fuel before starting

the engine.

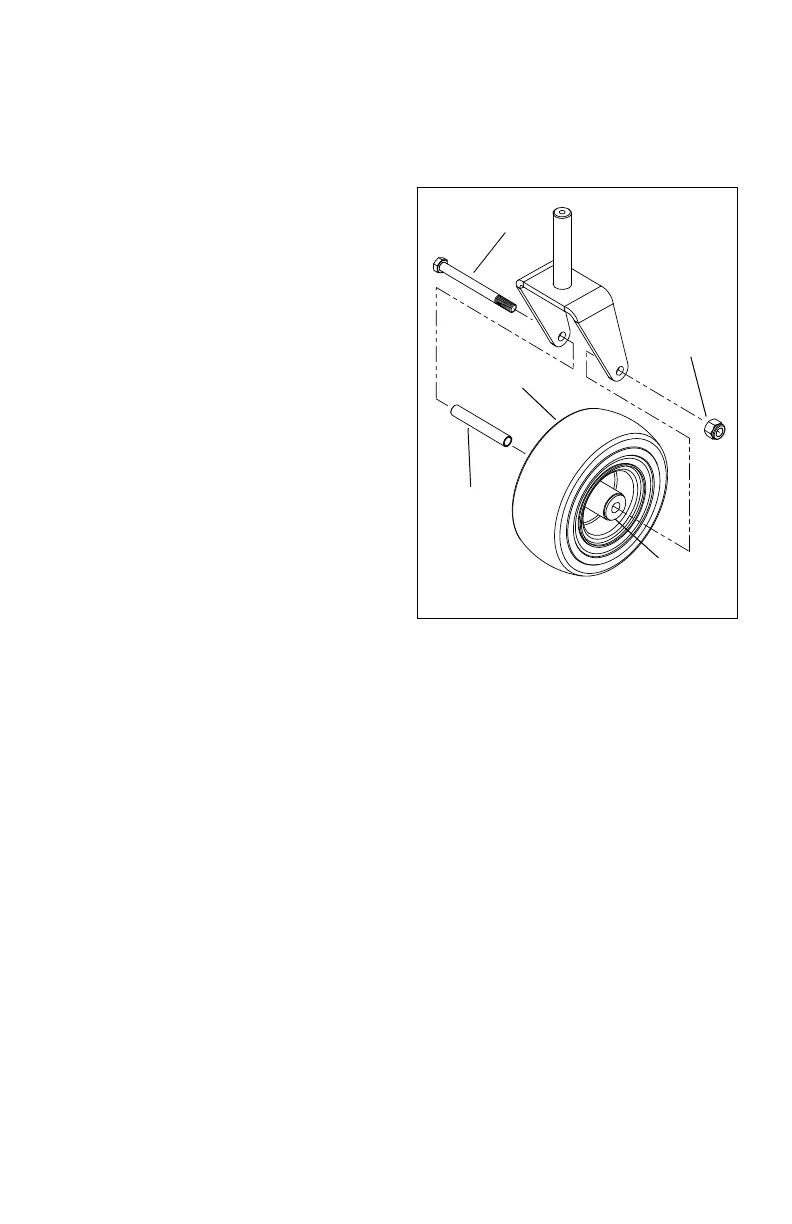

Servicing Caster Wheel Roller

Bearings

1. Park unit safely. See Using the Parking

Brake on page 13.

2. Raise and securely support the front of

the mower.

3. Remove nut (A), hex bolt (B) and wheel

assembly (C).

4. Remove bearing sleeve (D), bearing

retainer (E), and roller bearing (F) from

wheel.

5. Clean bushing and roller bearing and

pack with clean grease.

6. Install wheel assembly (C), roller bearing

(F), bearing retainer (E), bearing sleeve

(D), bolt (B) and nut (A).

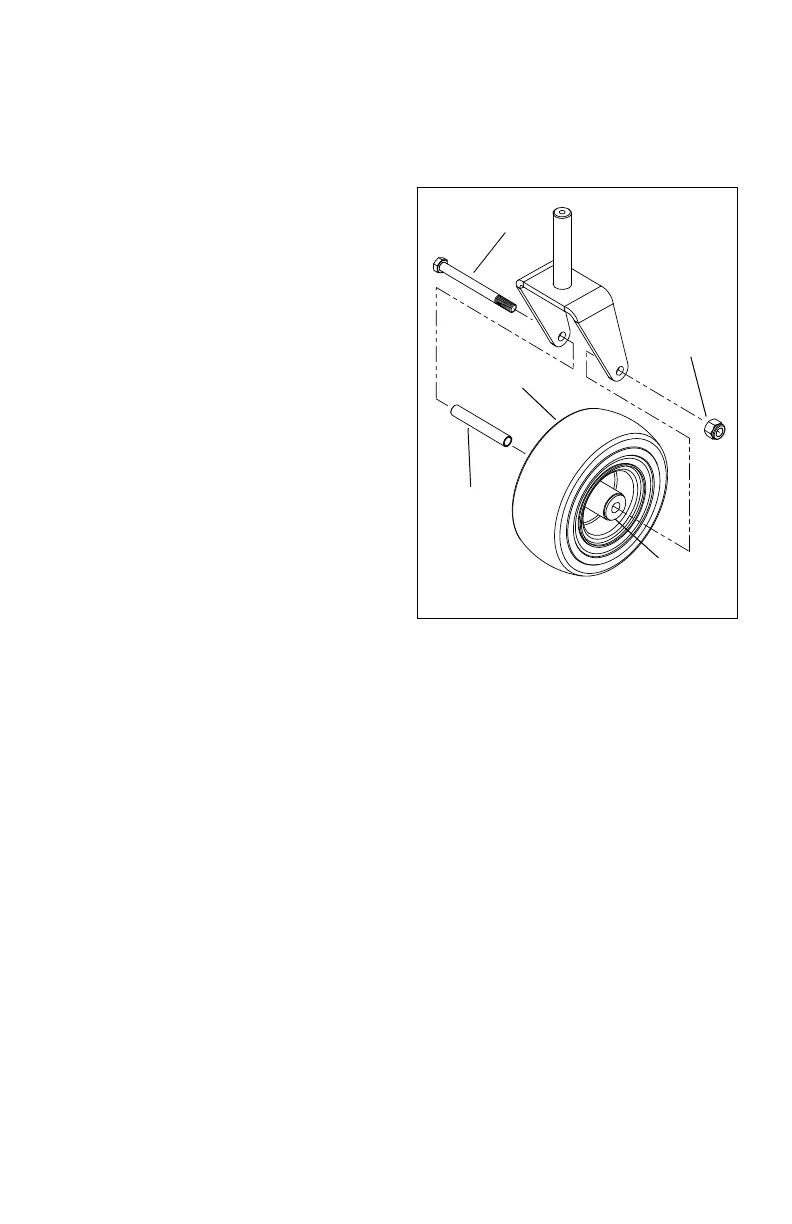

Replacing Caster Pivot Bearing

Bushings

1. Park unit safely. See Using the Parking

Brake on page 13.

2. Raise and securely support the front of

the mower deck.

3. Support caster yoke/wheel assembly.

4. Remove hex bolt (A), lock washer (B)

and flat washer (C) from caster yoke (E).

Lower caster yoke/wheel assembly from

caster weldment.

5. Remove and discard upper and lower

bushings (D) from caster weldment.

Loading...

Loading...