D Series Modular Air-cooled Scroll Chillers

34

(3) Close the main power switch.

(4) Check if the voltage between terminals keeps balance within deviation of 2%.

(5) Check if the power consumption of the unit complies with the rated value on the nameplate.

(6) Be sure the power cord is capable of carrying the rated current on the nameplate.

(7) Be sure all valves of water and refrigerant pipeline are placed properly.

(8) Reset all hand reset control elements.

(9) Be sure all sensor are placed installed properly.

7.2 Requirements on Water System and Water Quality

Be sure to open the water pump after the water system has been ushed times and the water quality

has met the requirements and meanwhile be sure the water ow rate and pressure are within the allowable

range.

The industrial water generates little scale when used as the refrigeration medium while the well or river

water will generate much more scale and sands which would reduce the ow rate of the evaporate and

cause freezing. Therefore, the well or river water must be rstly treated with the water softening equipment

and analyze the PH, heat conductivity, Cl ion, and S ion before use.

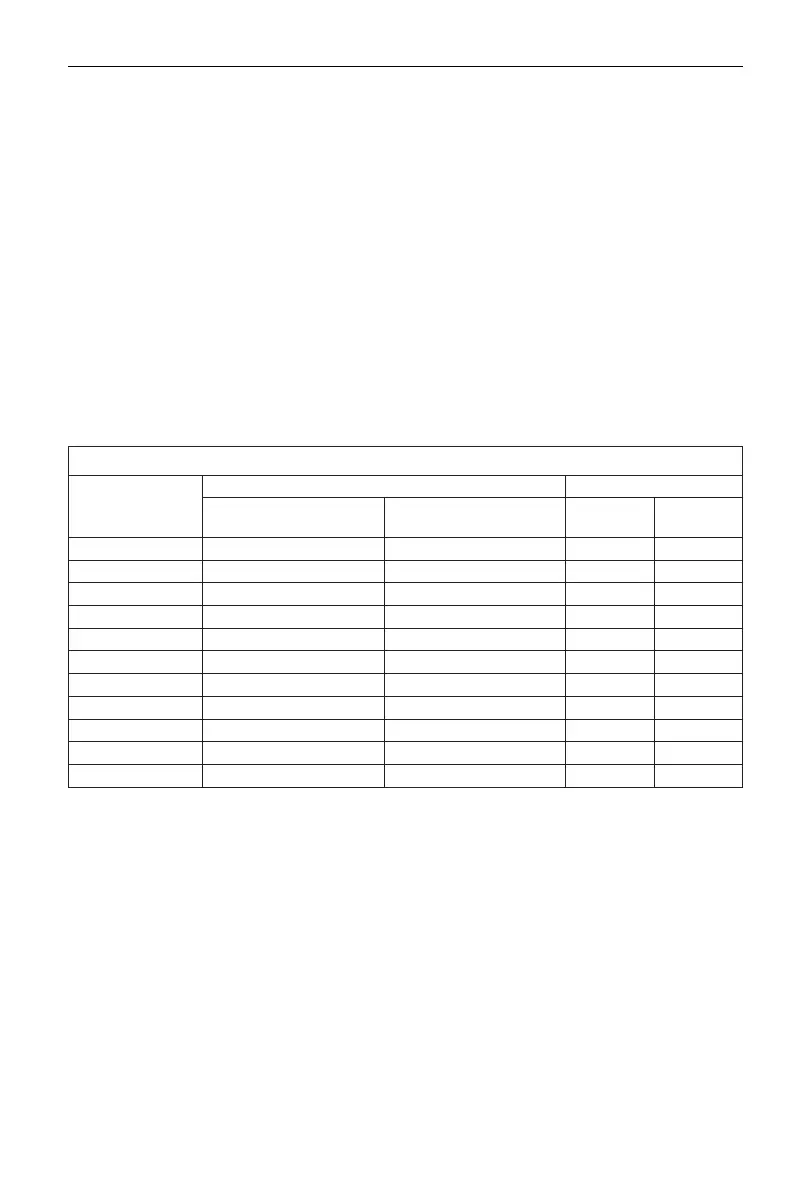

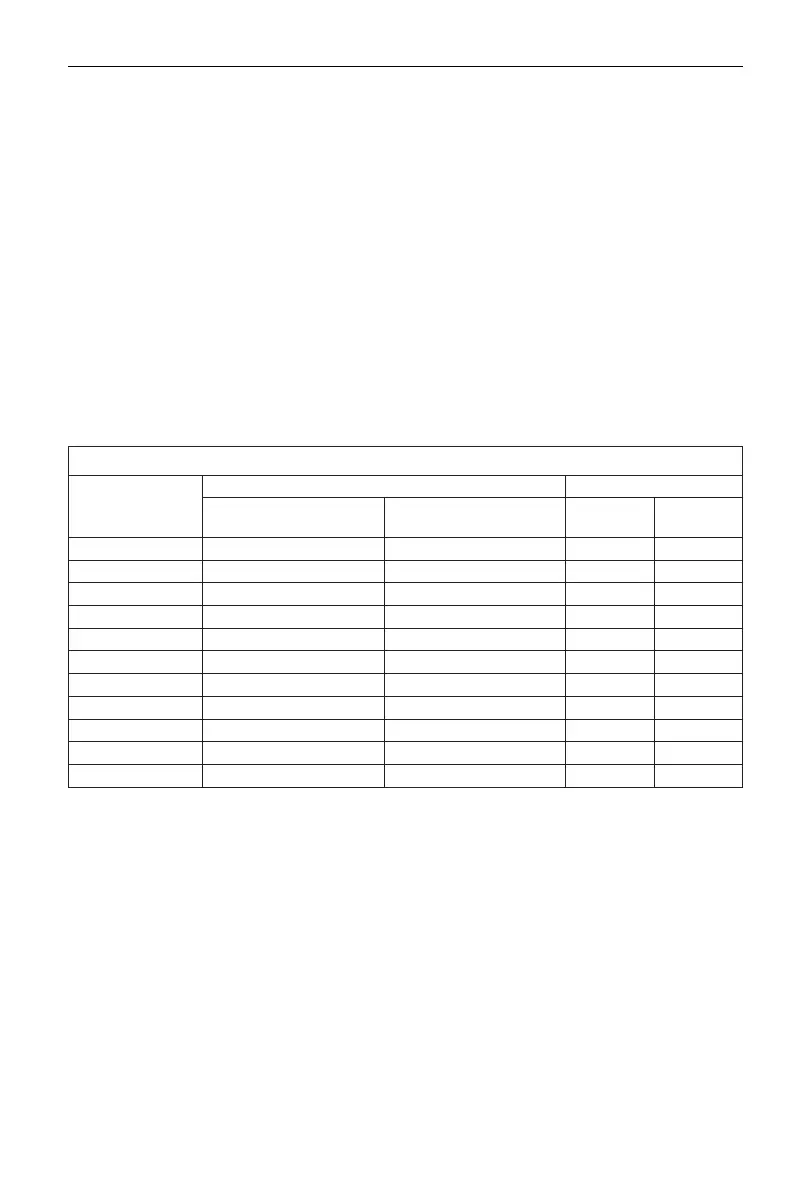

Water Quality Requirement

Items

Chilled water Potential effect

Circulating water

(<20

℃

)

Supply water Corrosion Scale

PH 6.5~8.0 6.5~8.0 ○ ○

Heat Conductivity <200uV/cm(25

℃

) <200uV/cm(25

℃

)

Cl ion <50ppm <50ppm ○

SO

4

ion <50ppm <50ppm ○

Fe <1ppm <0.3ppm ○ ○

Basic ion <50ppm <50ppm

Hardness <50ppm

<50ppm ○

S ion / /

Amonia ion / /

Si <30ppm <30ppm ○

Na ion / /

NOTE: “○” indicate possible corrosion or scale.

Even if the water qualify is under the strict control, calcium dioxide or other minerals will still form on the

surface of the heat exchanger which will affect the heat exchange efciency and be eliminated by formic

acid, lemon acid, acetic acid or other organic acid.

7.3 Trial Run

See the operation manual of the applicable controller for more details.

(1) When the unit has not been used for a long period or the ambient temperature is quiet low, keep the

unit energized 8 hours before startup to preheat the crankcase of the compressor so as evaporate

the liquid refrigerant inside the compressor which otherwise would cause adverse effect on the

compressor.

(2) Be sure valves are opened properly to prevent the compressor from being damaged by the abnormal

high pressure.

(3) Carefully adjust the ow control valve and the shutoff valve of the chilled water system to make the

ow rate meet the rated value on the nameplate.

Loading...

Loading...