GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

214

Step 5: Remove faulty compressors.

Confirm faulty compressors, including number of faulty ones, compressor position, and model.

Handling procedure varies with compressor model.

Inverter compressors and oil quality

If the inverter compressor is damaged, or the oil of the fixed speed compresor is contaminated,

remove the inverter compressor.

After the compressor and oil separator are removed, check oil quality. If oils are contaminated,

replace the compressor, oil separator, and gas/liquid separator. If oil changes to black, check oils of

other modular units. The check procedure is similar to the preceding.

Note: Before replacing the faulty compressors, make sure to block their openings with tapes. They

should be kept intact for further analysis.

Step 6: Check system parts.

If system oil is contaminated, check unit parts, including oil separator, gas/liquid separator, and

storage tank.

1) Check oil separator.

Remove the oil separator. For the removal procedure, refer to step 4. Tilt the separator to draw oil

out into a container. Block the container for further factory inspection.

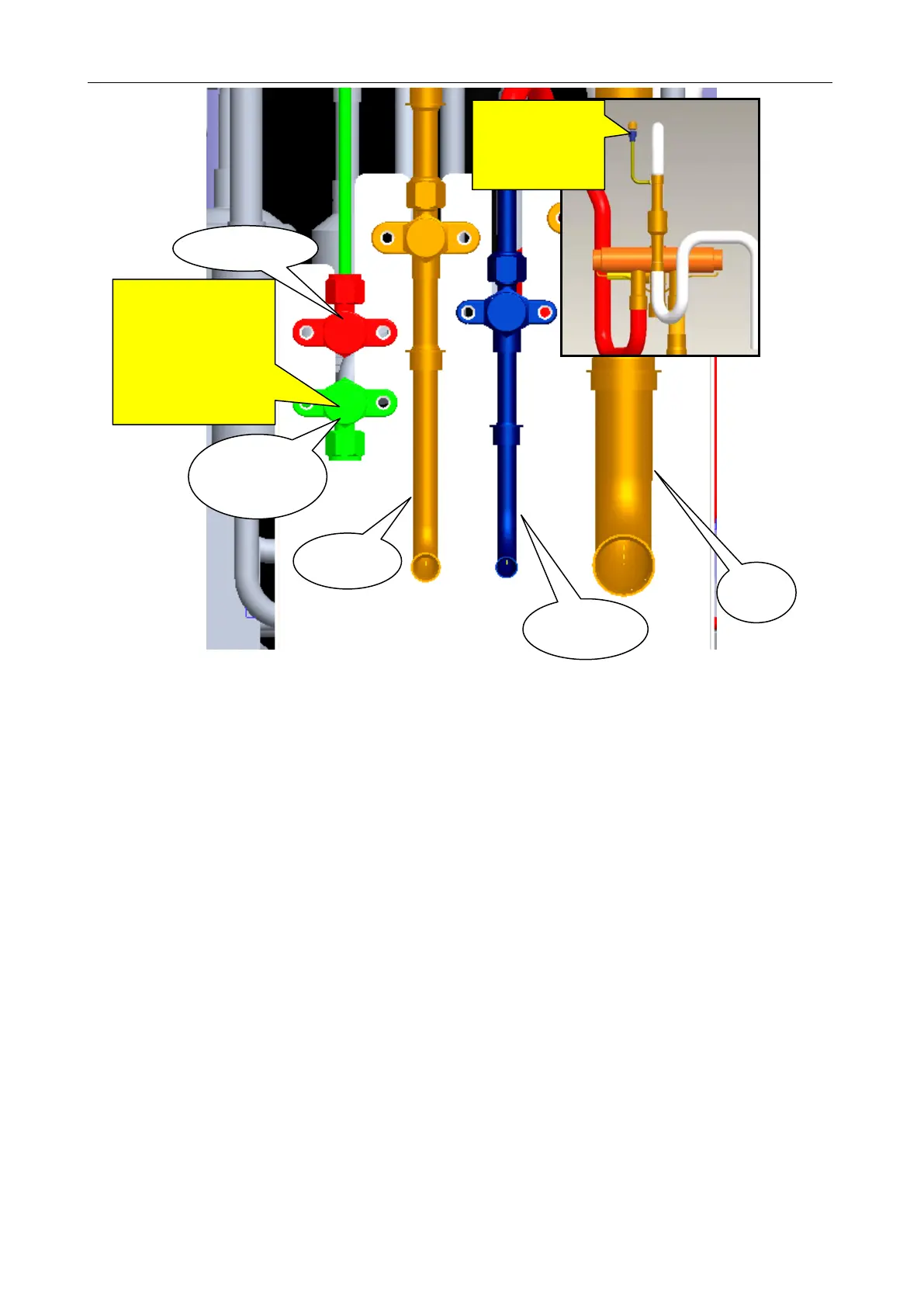

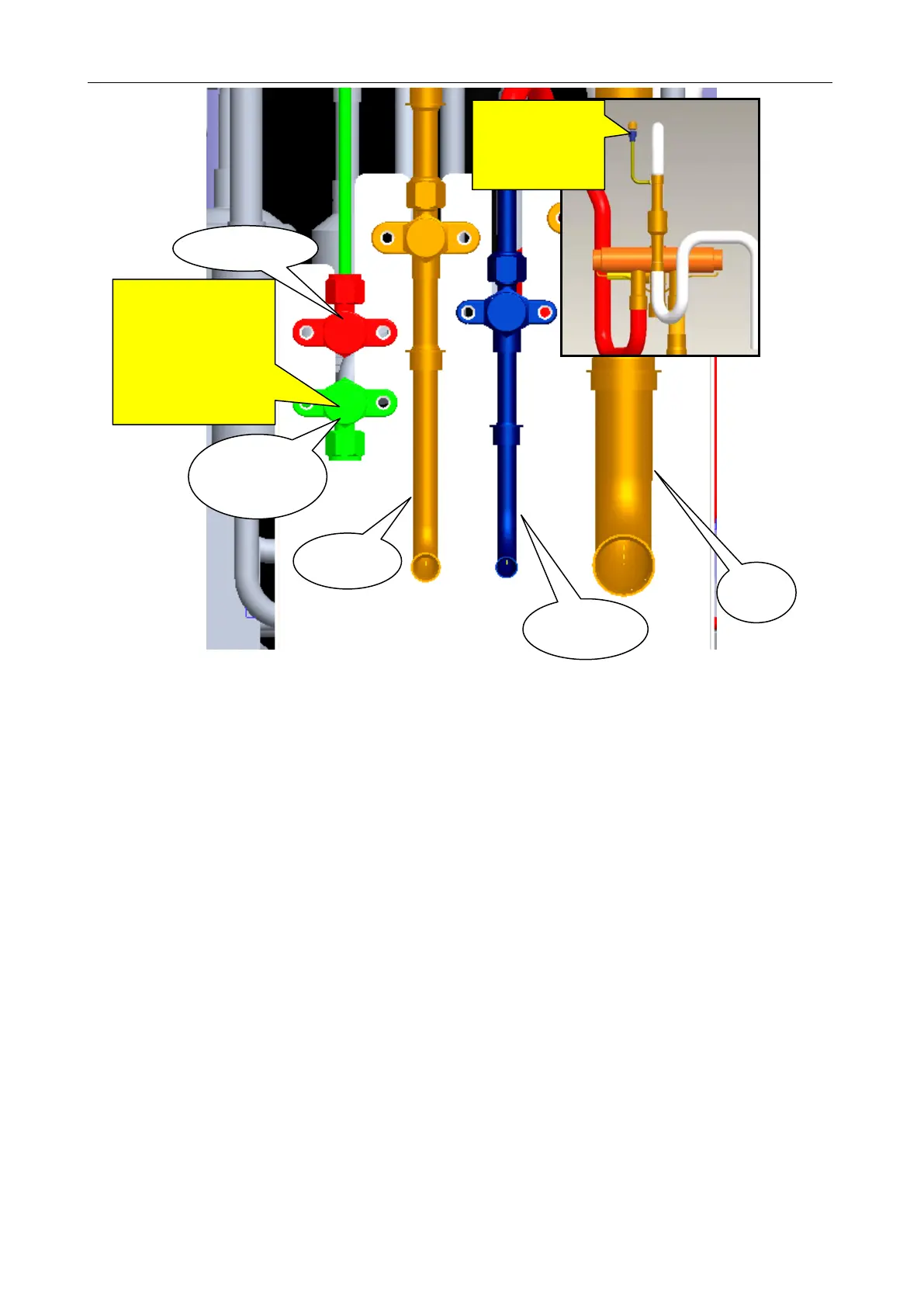

Refrigerant should be

released from the high

pressure side and low

pressure side at the

same time. Control the

release speed. At the low

pressure side, refrigerant

is released through the

low pressure check valve.

At the high pressure

side, refrigerant is

released through

the high pressure

sensor.

Loading...

Loading...