GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

64

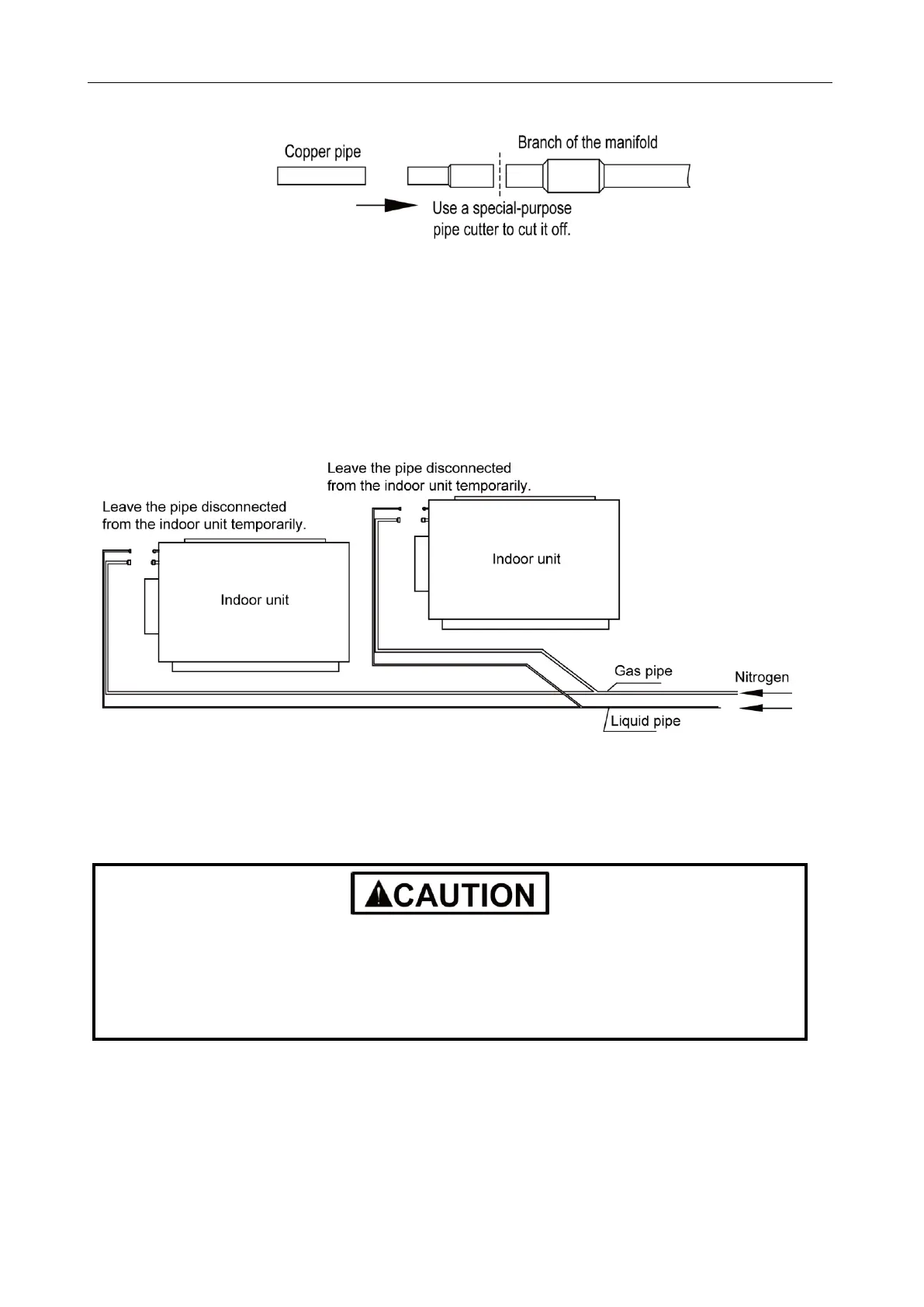

(8) Because the manifold structure is complex, perform with care to ensure tight insulation.

6.1.3.7 Pipe Cleaning by Nitrogen

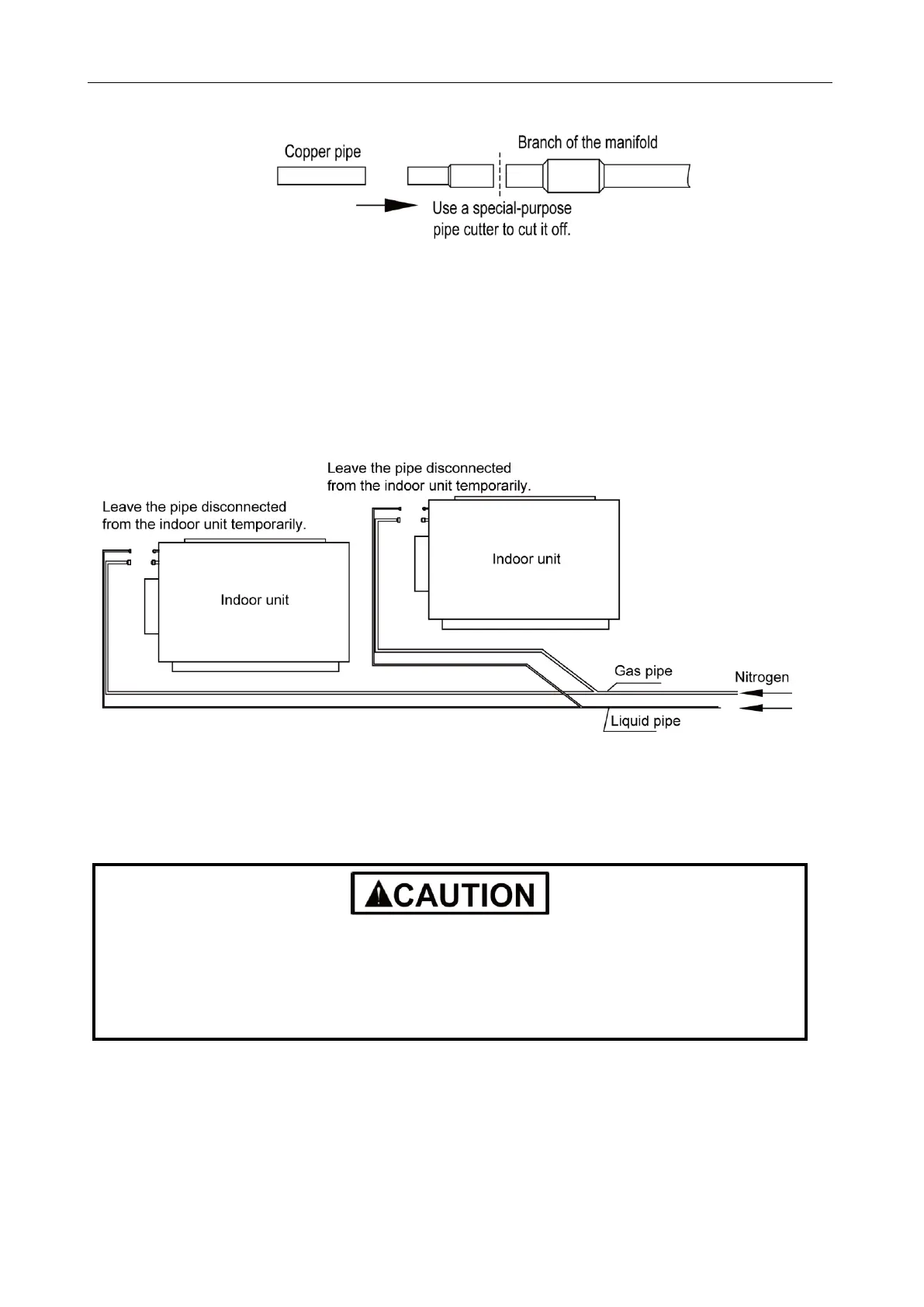

Before connecting the flare opening of the pipe to the IDU, connect the pressure regulator valve on

the nitrogen cylinder to the liquid pipe in the outdoor pipe system. Regulate the nitrogen pressure to

about 5 kgf/cm² and blow nitrogen into the pipe for 1 minute. Repeat this operation for three times till the

dirt and water are discharged. After cleaning the liquid pipe, perform the same operation to clean the gas

pipe.

Perform an air-tightness test and a vacuum test to the entire refrigerant pipe system after the

construction is finished.

There must be a secure distance between pipes. Pipes in different types must be fixed separately.

6.1.3.8 During refrigerant pipe installation, ensure a distance above 500 mm (19.7inch) between the pipe

and the electric box of the unit for maintenance. In a case when the space is not enough, the final piping

way must be determined by the technical personnel.

When all of the pipes of indoor unit finish welding, dry nitrogen must be used to blow and

clean the pipes. Otherwise, the remaining substance in pipeline will cause blockage or

leakage to the system (e.g. electronic expansion valve), which result in abnormal operation

or even damage the compressor.

Loading...

Loading...