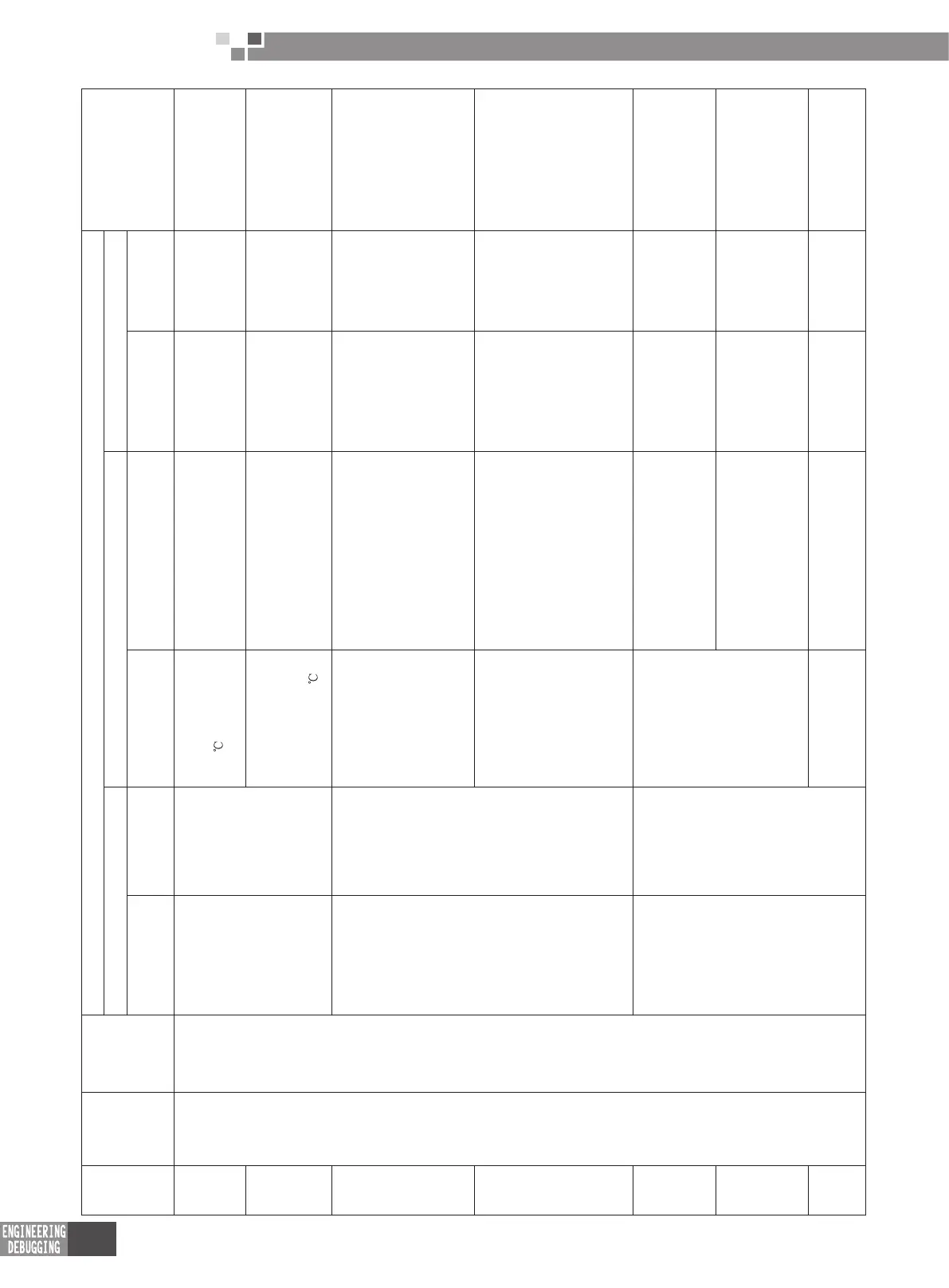

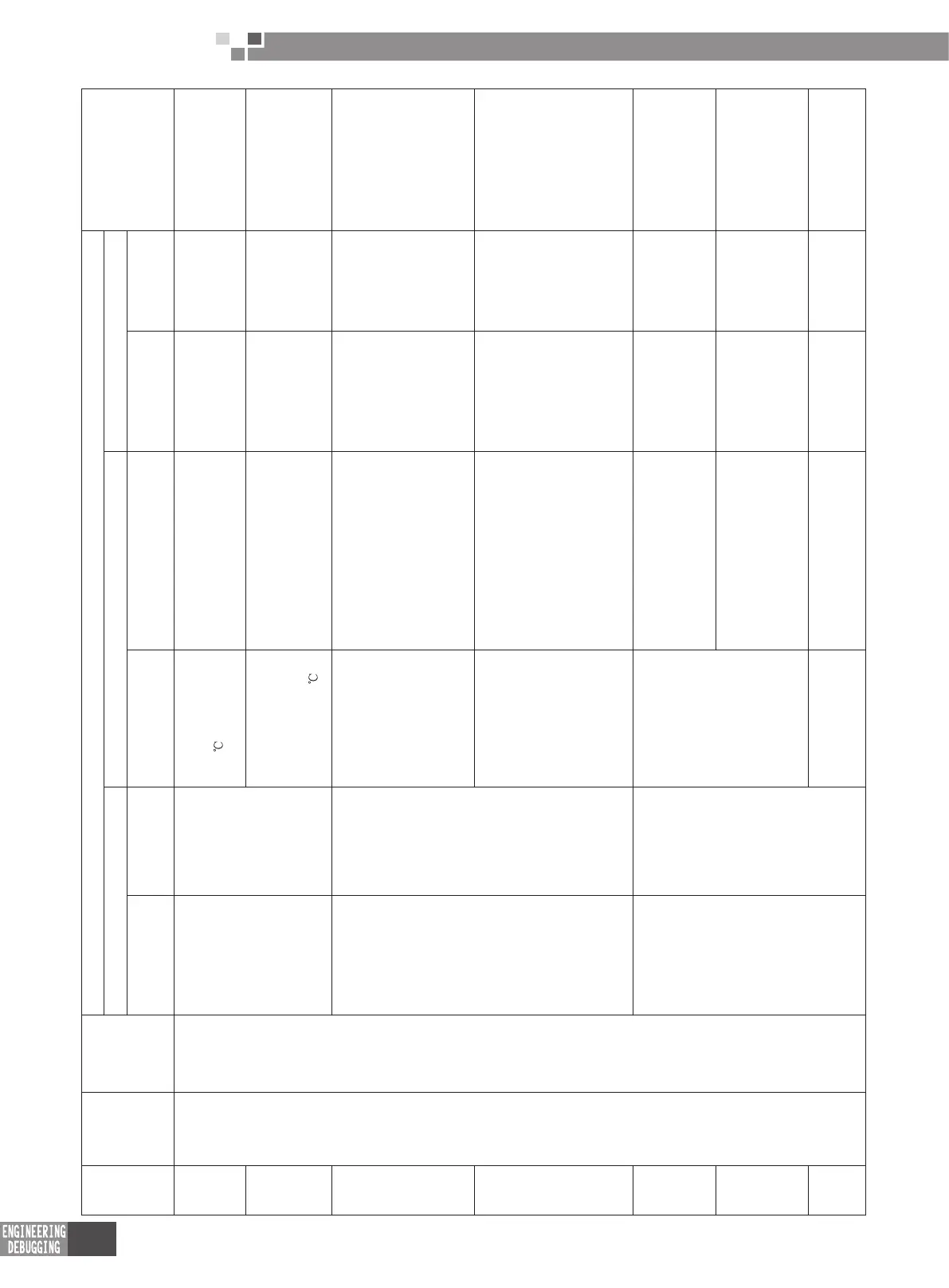

162

DC Inverter Multi

VRF Service Manual

S/N Class Trouble

Possible Cause

Troubleshooting

First-level reason Second-level reason Third-level reason

Description

of Cause

Method of

Conrmation

Description of Cause Method of Conrmation

Description

of Cause

Method of

Conrmation

7

Abnormal

system

pressure

Discharge

pressure

abnormally

increases.

3.The abmbient

temp is too high

when the unit

is running

——

3.1 Outdoor ambient

temp is more than

48

when cooling

operation.

Collect outdoor ambient

temp on spot.

—— —— Normal phenomenon.

8

3.2 Heating operation,

actual temp of return

air of the indoor

unit exceeds 30

.

Collect return air temp on spot. —— —— Normal phenomenon.

9

4. Pressure

transducer is

abnormal.

——

4.1 Inspection of high

pressure transducer

is abnormal.

Stop the complete unit and check

the equalizing pressure of high and

low pressures after 20 min. Then,

transfer the pressure value to the

corresponding saturation temp and

compare it with outdoor ambient

temp. If the temp difference is

more than 5 it is abnormal.

—— ——

Replace high

pressure transducer

10

4.2 High pressure

transducer and low

pressure transducer are

wrongly connected.

When the system is running, check

the high pressure of gas pipe

and liquid pipe. Then, transfer

them to the corresponding temp

value which shall be respectively

compared with the corresponding

temp value detected by system.

If the temp difference is greater

than 5 there is abnormality.

—— ——

Exchange these two

pressure transducers.

11

5. High pressure

switch abnormally

operates.

“E1”code will be

displayed after

energization

of the unit.

5.1 The connection

between high pressure

switch and mainboard

is abnormal.

——

5.1.1 Pressure

switch is not

connected with

mainboard.

—— Connect them again.

12 ——

5.1.2 Connecting

wire between

pressure switch

and mainboard

is abnormal.

——

Replace the

connecting wire.

13

5.2High pressure

switch is damaged.

—— —— ——

Replace pressure

switch.

Loading...

Loading...