ROUTINE MAINTENANCE

CAUTION: See **WARNING** on Page 1

After the ERV has been put into operation, an annual inspection and maintenance

program should be set-up to preserve reliability and performance. Include the

following items in this program,

• BELTS • REMOVAL OF DUST/DIRT

• FASTENERS • FILTER MAINTENANCE

• SET SCREWS • ENERGY WHEEL CASSETTE

BELTS

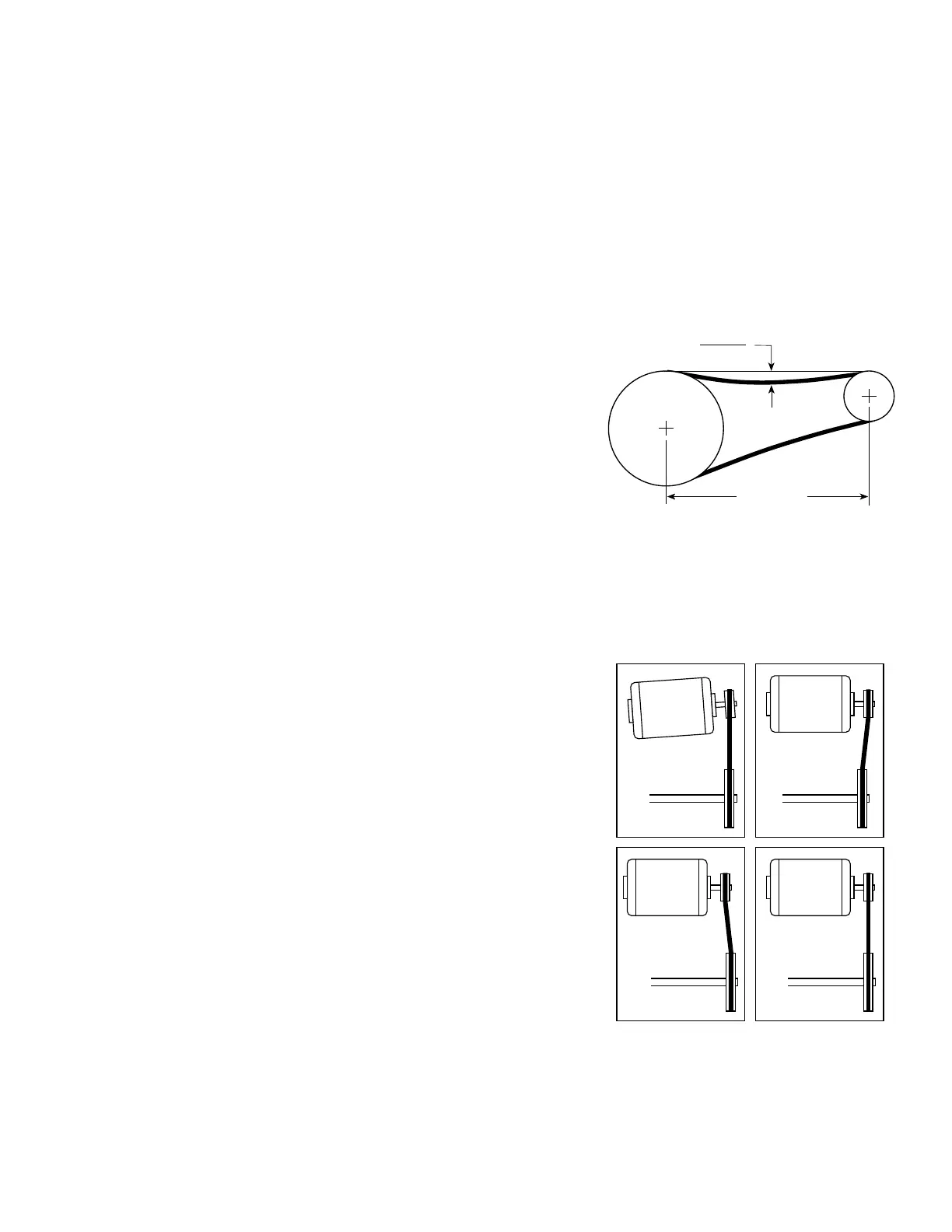

Premature belt failures are frequently caused by improper belt tension

(either too tight or too loose) or misaligned pulleys. The proper tension

for operating a V-belt is the lowest tension at which the belts will not

slip at peak load conditions. For initial tensioning, the proper belt

deflection half way between pulley centers is

3

/8

inch

per foot of belt

span. The belt deflection should be

3

/8

inch using moderate thumb

pressure at midpoint of the drive (See Figure 6).

Check belt tension two weeks after start-up and periodically thereafter.

To adjust belt tension, simply loosen four fasteners (two on each side

of the motor plate) and slide the motor plate away from the fan shaft

until proper belt tension is attained. On some ERVs, fasteners attaching

the motor to the motor plate must be loosened in order to adjust the

belt.

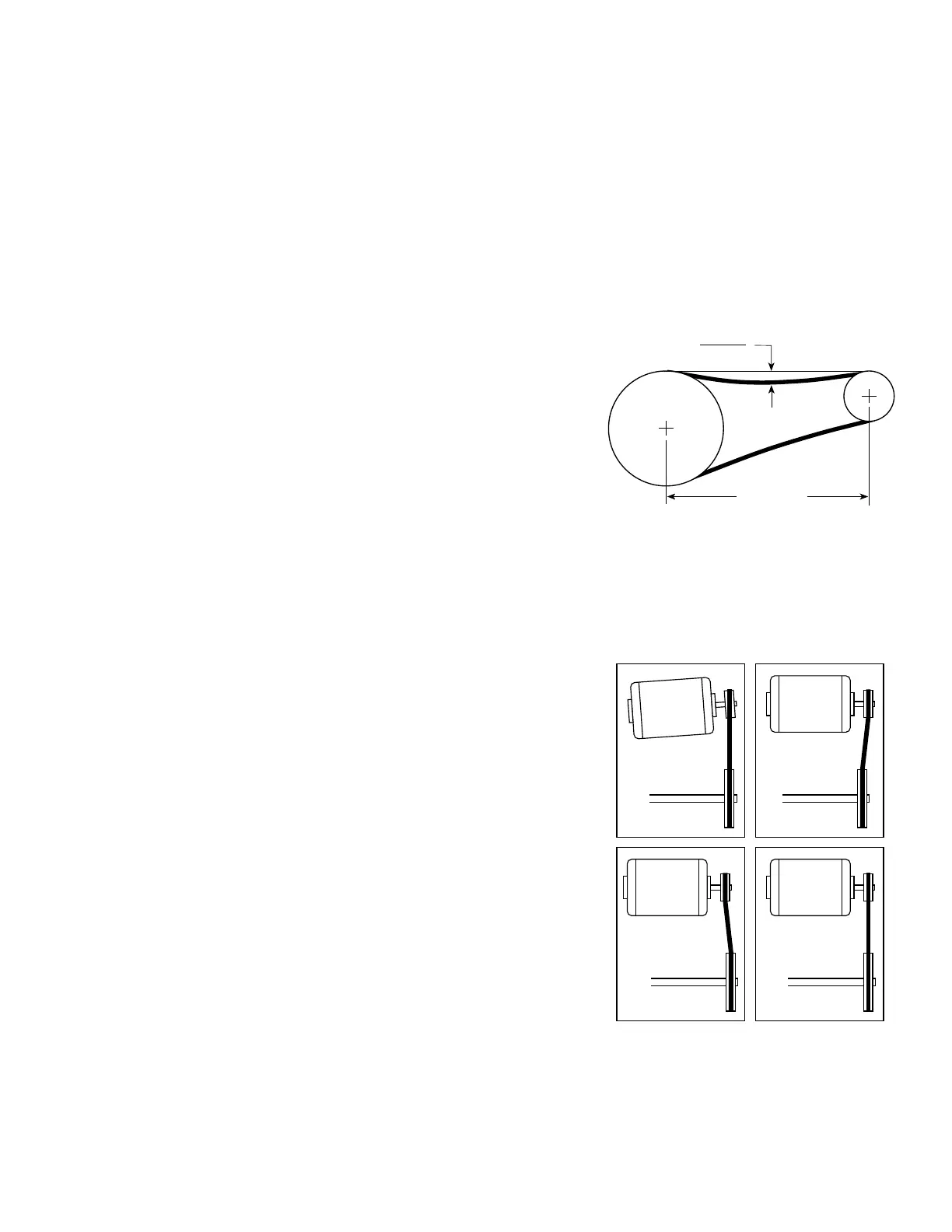

It is very important that the drive pulleys remain in proper alignment

after adjustments are made. Misalignment of pulleys will result in

premature belt wear, noise, vibration and power loss.(See Figure 7).

Maintain belts and motors through the provided access panels.

FASTENERS AND SET SCREWS

Any fan vibration has a tendency to loosen mechanical fasteners. A

periodic inspection should include checking all fasteners and set

screws for tightness. Particular attention should be paid to set screws

attaching the fan wheel to the shaft and the shaft to the bearings.

Loose bearing set screws will lead to premature failure of the fan shaft.

REMOVAL OF DUST AND DIRT

Dirt clogs cooling openings on the motor housing, contaminates

bearing lubricant and collects on fan wheel blades causing severe

imbalance if left unchecked. The exterior surface of the motor, inlet area

and entire fan wheel should be thoroughly cleaned periodically. Use

caution and do not allow water or solvents to enter the motor or

bearings. Under no circumstances should motors or bearings be

sprayed with steam or water. Maintenance to these components is

achieved through the provided access panels.

Loading...

Loading...