ERV-251

First, remove the drive belts and the

collars on both bearings. On the pulley

side of the cassette remove the (4)

fasteners that hold the bearing support

channel in place. Once the bearing

support is removed the wheel can be

pulled from the cassette. To replace

the wheel reverse this procedure.

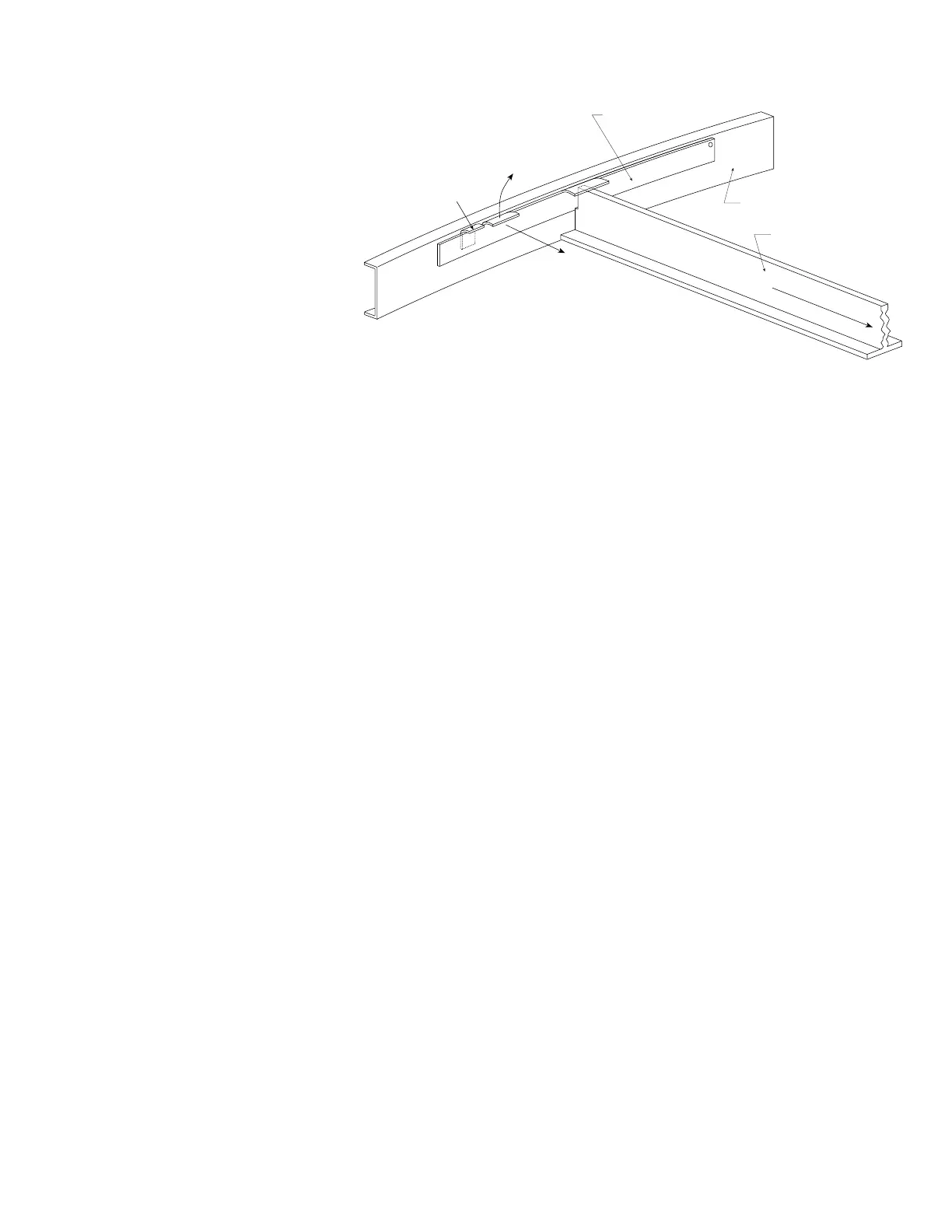

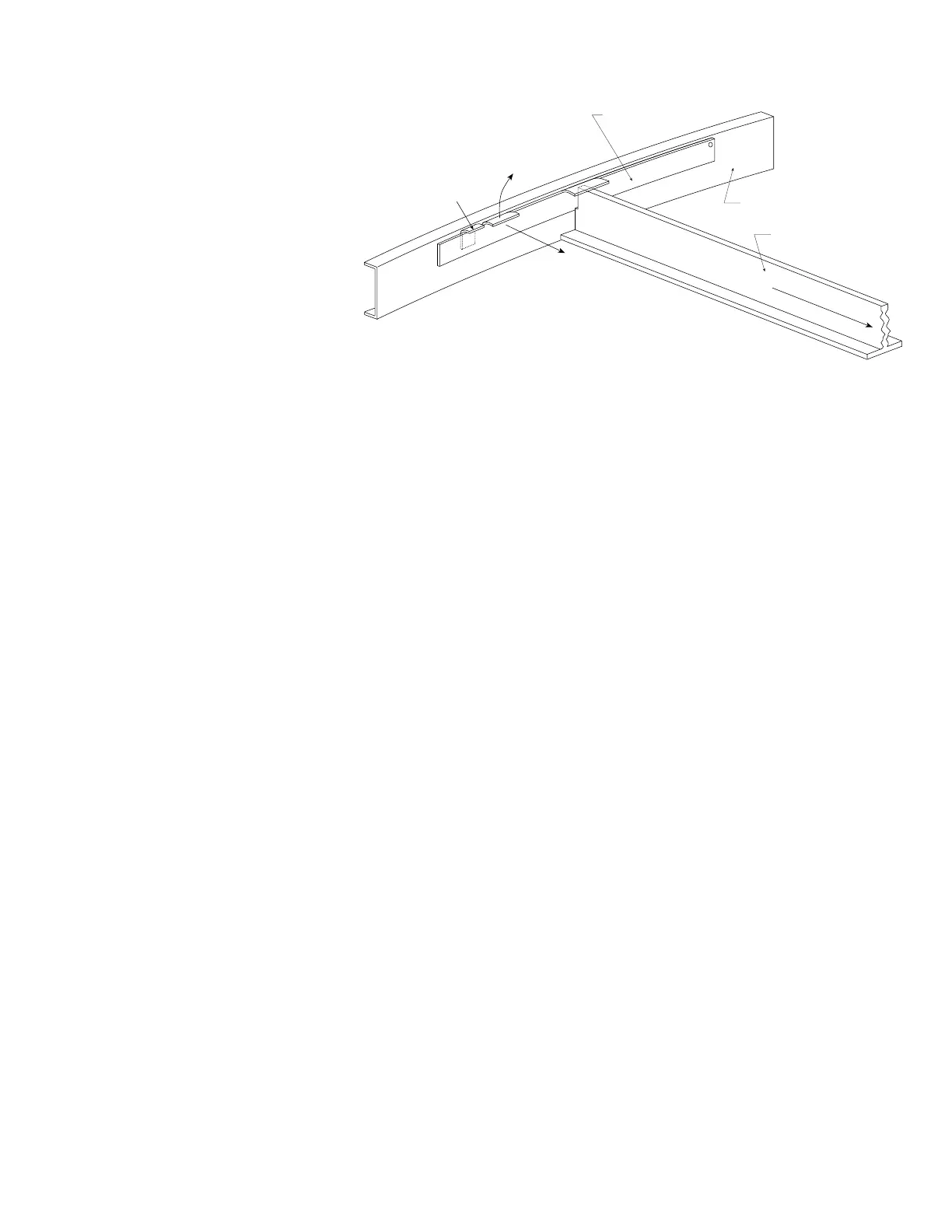

ERV-361, 521, 581, 522 & 582

(stainless steel rim)

Steel retainers are located on the inside

of the wheel rim (see Figure 11). Push

the retainer towards the center of the

wheel, then lift up and away to release

segments.

17

NOTE: PLACE RETAINERS BACK IN THE ORIGINAL

POSITION BEFORE ROTATING THE ENERGY

RECOVERY WHEEL. OTHERWISE DAMAGE

TO THE RETAINER WILL OCCUR.

REMOVING THE ENERGY RECOVERY WHEEL OR SEGMENTS

FIGURE 11

RECOMMENDED CLEANING PROCEDURE FOR ENERGY RECOVERY WHEELS

First, remove the energy recovery wheel segments by following the instructions on this page. (For one-piece

wheels smaller than 30 inches in diameter, remove the wheel from the cassette.)

Wash the segments or small wheels with a non-acid based (evaporator) coil cleaner or alkaline detergent

solution. Non-acid based coil cleaner such as KMP Acti-Clean AK-1 concentrate in a 5% solution has been

demonstrated to provide excellent results. Do not use acid based cleaners, aromatic solvents,

temperatures in excess of 140°F or steam; damage to the wheel may result. Soak in the cleaning

solution until grease and/or tar deposits are loosened. Internal heat exchange surfaces may be examined by

separating the polymer strips by hand. (Note: some staining of the desiccant may remain and is not harmful

to performance.)

After soaking, rinse the dirty solution from the wheel until the water runs clear. Allow excess water to drain

prior to replacing segments in the wheel or reinstalling the wheel in the cassette. A small amount of water

remaining in the wheel will be dried out by the airflow.

FREQUENCY OF ENERGY WHEEL CLEANING

A regular cleaning cycle must be established for the energy recovery wheel in order to maintain optimum

sensible and latent energy transfer. In reasonably clean environments such as schools, offices or retail stores,

the energy recovery wheel should be inspected annually and cleaned as needed.

For applications experiencing unusually high levels of tobacco smoke, such as lounges, nightclubs, bars and

restaurants, washing of the energy recovery wheel every six months may be necessary to maintain latent

energy (water vapor) transfer efficiency.

Failure to follow a regular cleaning cycle for the energy recovery wheel can result in significant energy transfer

performance losses.

Loading...

Loading...