12

Maintenance

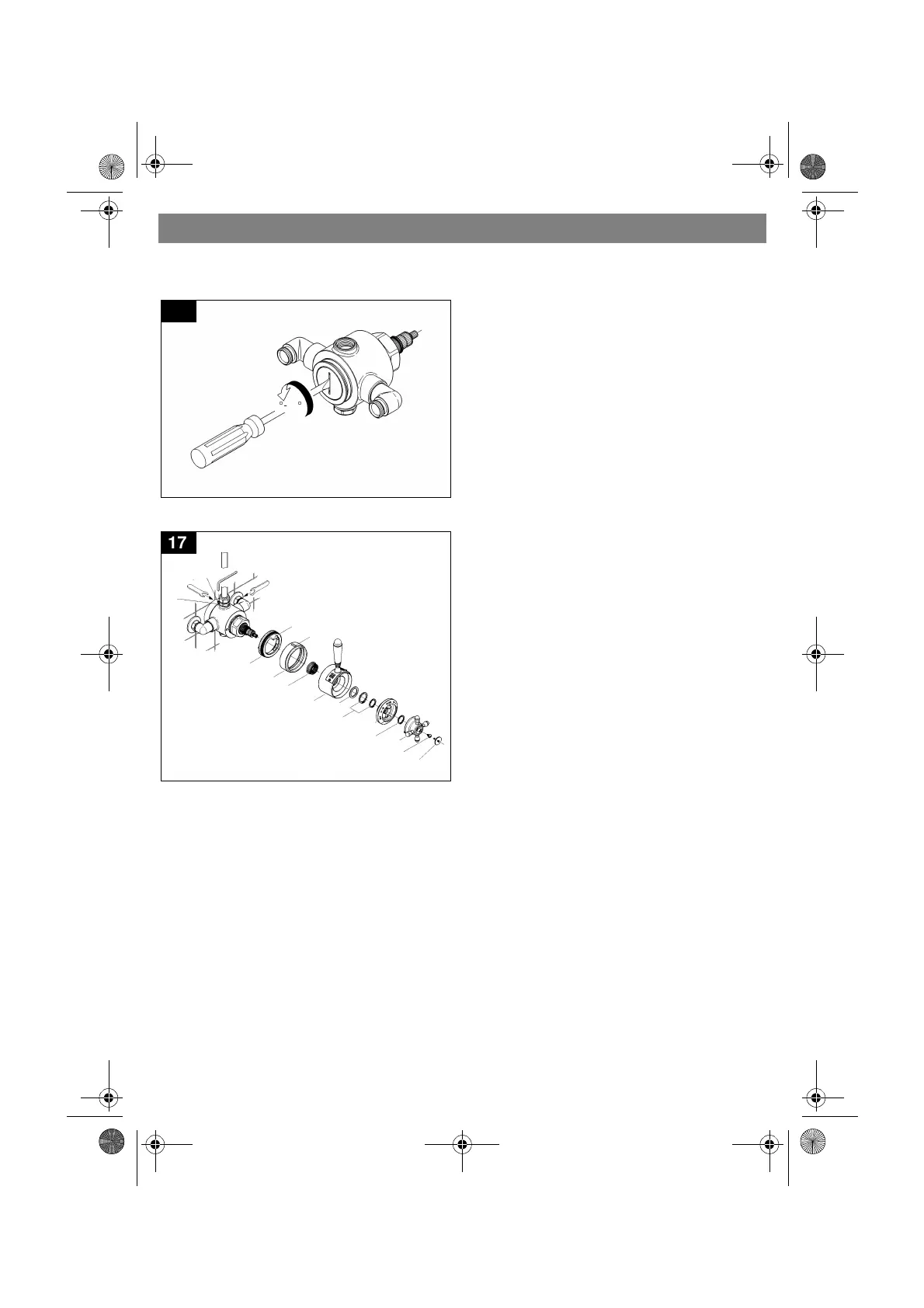

7.Unscrew seat 1/8 to 1/6 turn (45qto

60q), see Fig. [16].

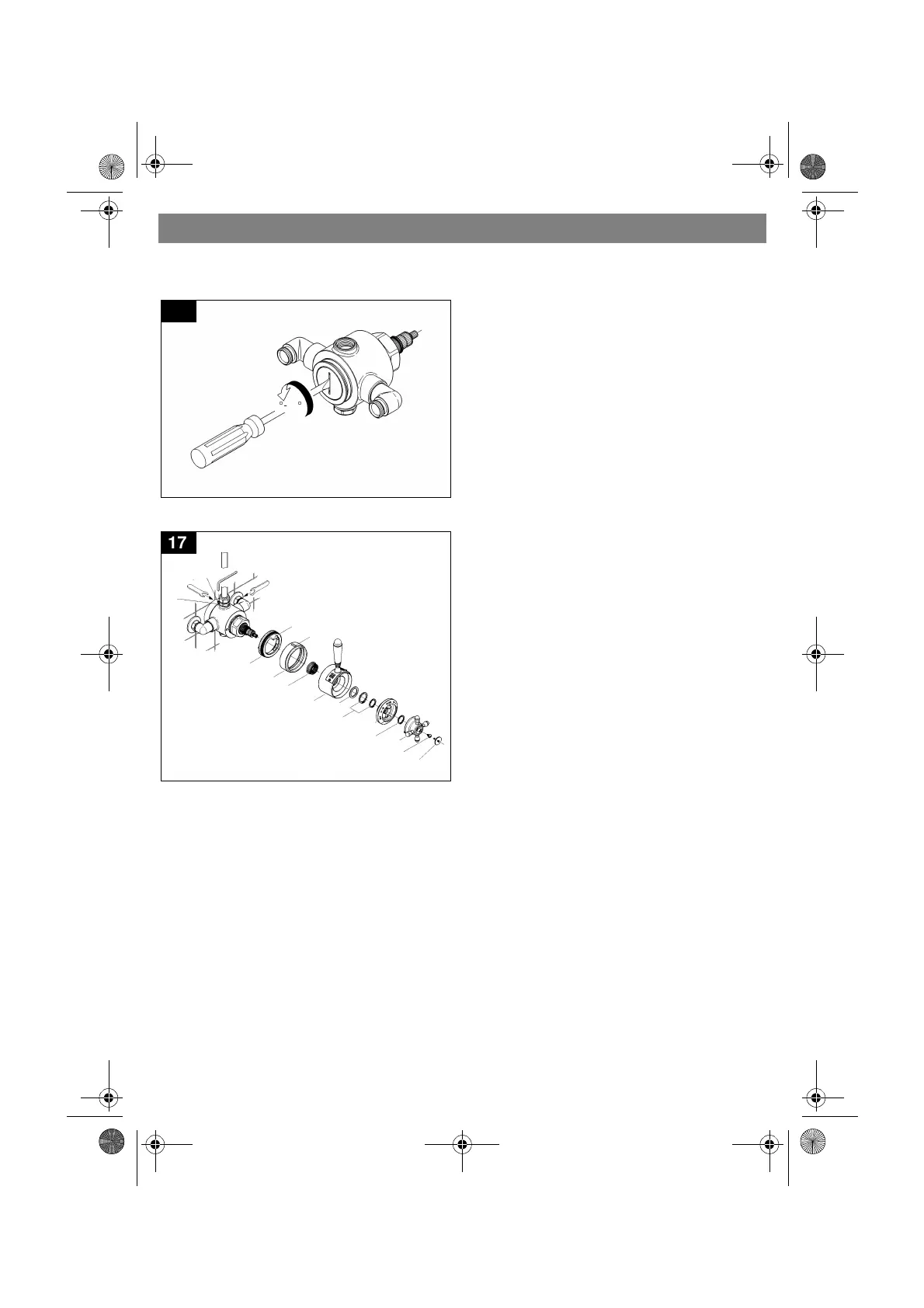

8.Slide valve on the supplies, see Fig. [17]

9.Tighten set screw (D1) and compression

nuts.

10.Install shower and tighten outlet

nipple (L).

11. Push on stop ring (T) with catch (T1)

on top.

12.Reinstall cover ring (S) with mark (S1)

on top.

13.Push on adapter (R).

14.Push on shut-off lever (Q) in closed

position.

15.Reinstall washer (Q2) and fix with cir-

clips (Q1), the smaller one is to be

placed in the middle of the unit stem.

16.Push on scale ring (P) with WARM on

top and fix with clip (P1).

17.Reinstall the temperature cross

handle (O) in position hot water.

18.Fix temperature cross handle with

screw (N) and cover with cap (M).

Readjustment is necessary after every

maintenance operation on the control unit,

see chapter “Adjustment” on page 10.

II.Non-return valve, see spare parts

drawing on page 3, 4 and Fig. [12].

1.Same procedure as for control unit, see

Fig. [12], points 1, 11 and 12.

2.Unscrew elbow, see spare parts drawing

on page 3 and 4.

3.Remove threaded ring with flow

limiter (9.1) if installed.

4.Take out and replace non-return

valve (9.2).

Reassemble in reverse order.

Only genuine GROHE replacement parts

must be used.

16

45

q

-60

q

P1

17

M

N

S

T

2

.

5

m

m

2

4

m

m

R

T1

S1

Q1

L

2

4

m

m

D1

Q

O

P1

Q2

P

956212.book Seite 12 Mittwoch, 19. Dezember 2001 8:04 08

Loading...

Loading...