4

The air motor repeats Upstroke & Downstroke in continuous cycle to produce a reciprocating motion, driven

by compressed air. This motion is transferred via a connecting rod to the piston in the Pumping Section.

During every upstroke, non return valves (with spring & ball check) get opened & the piston lifts the grease.

During every downstroke, non return valves get closed & the piston discharges grease from the outlet valve.

Closing the Grease Control Valve shuts off the air motor & pump stops dispensing grease.

WORKING OF PUMP

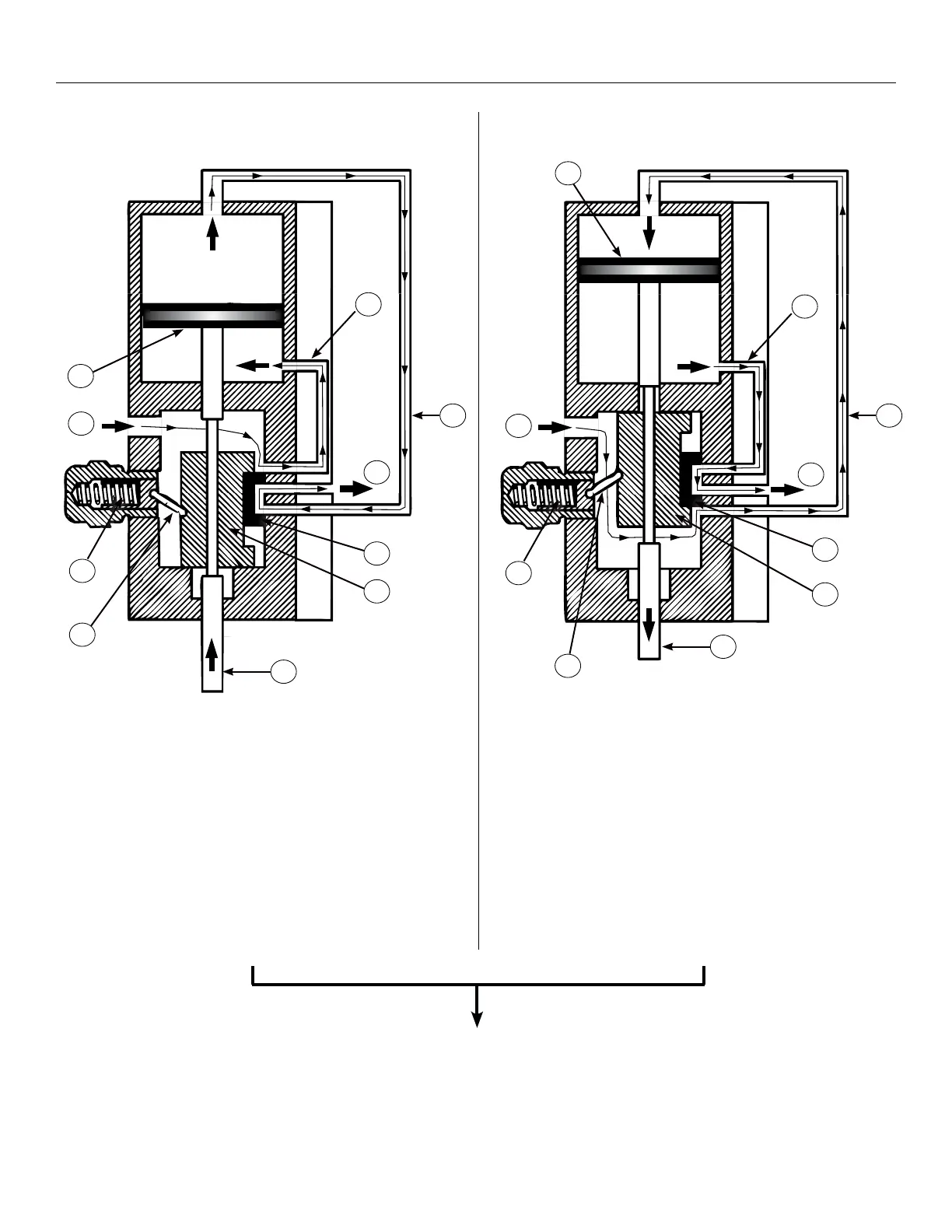

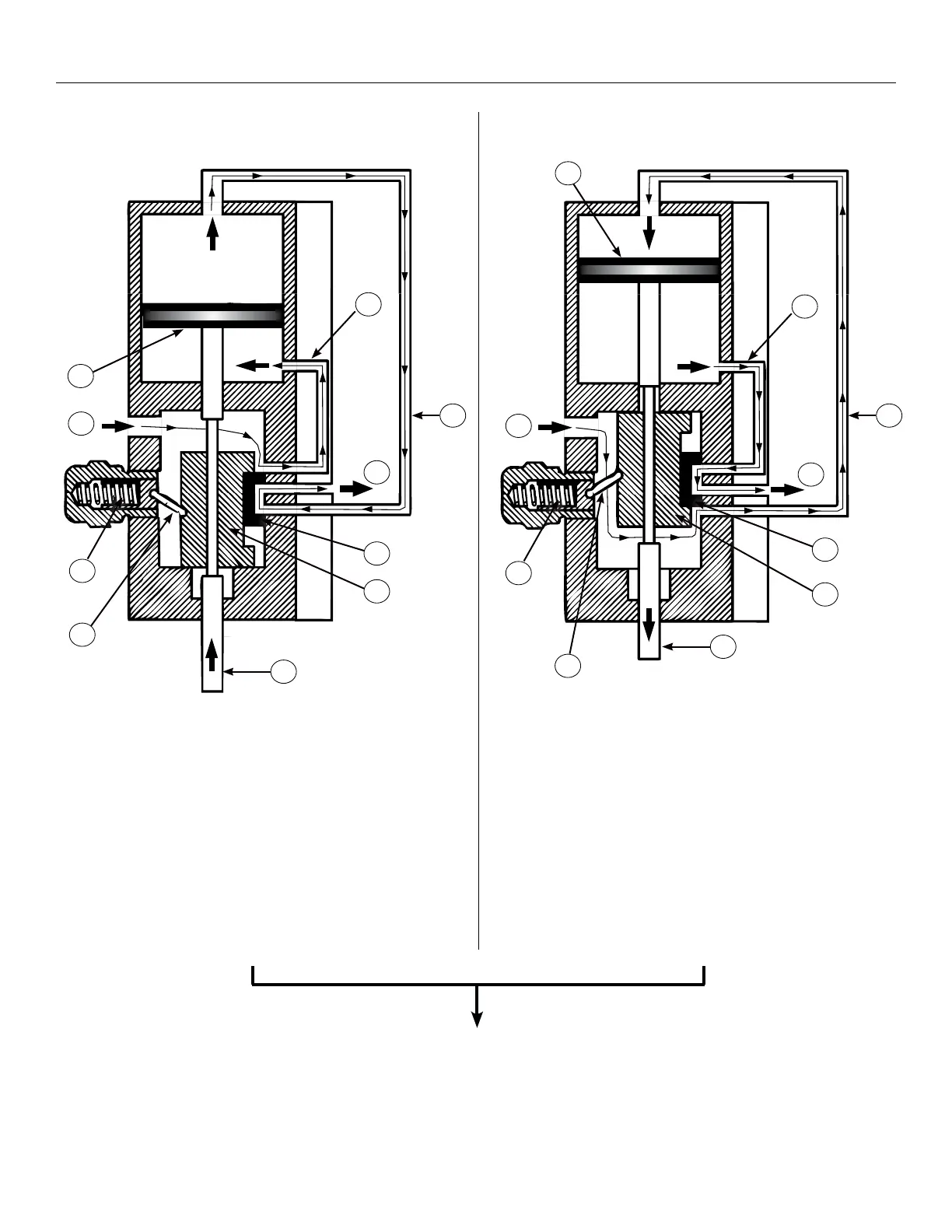

UPSTROKE DOWNSTROKE

A

B

C

D

G

H

J

I

UPSTROKE -

When Grease Control Valve is opened, compressed air enters

at arrow A and passes through passage B to the underside of

the Piston C, driving the Piston C and Piston Rod D upwards.

The air above the Piston is evacuated through passage E,

past the Slider Valve F and out at arrow G.

The Piston approaches top dead centre and Piston Rod D

makes contact with the Slider Rod H. Now the Slider Rod H

starts moving up with the Piston Rod D.

DOWNSTROKE -

The incoming air is now led via passage E to the upper side

of Piston C, driving it and the Piston Rod D downwards.

The air under the Piston C is evacuated through passage B,

past the Slider Valve F and out at arrow G.

The Piston approaches bottom dead centre and Piston rod

D makes contact with the Slider Rod H. When Slider Rod H

passes its centre position, the Pusher Spring I and Pusher

Button J snap it over to its lower position.

F

A

B

C

D

G

E

H

J

I

F

E

Fig. 4 Fig. 5

Loading...

Loading...