7

MAINTENANCE & REPAIR (Refer to Exploded View - Page 12)

Service Precautions

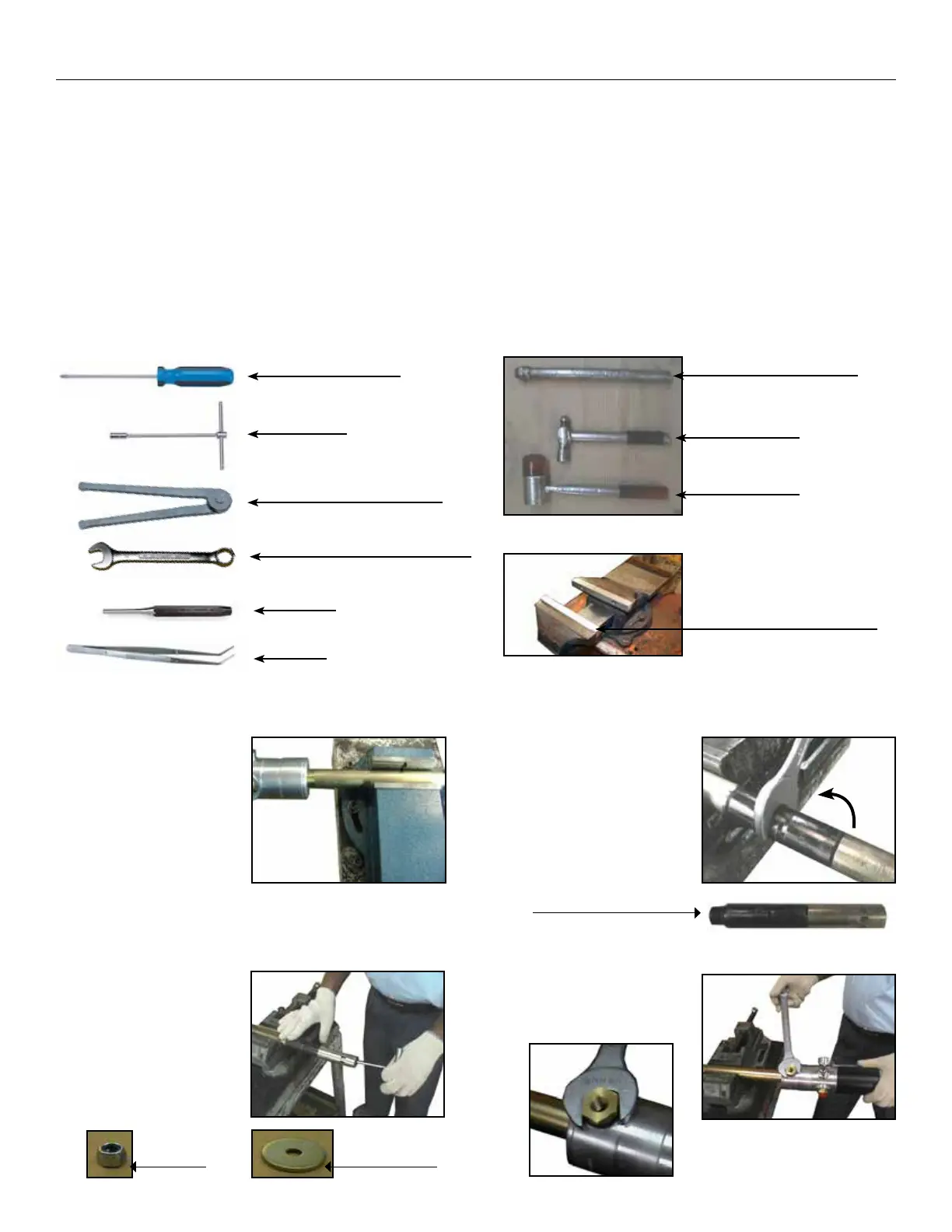

Recommended Tools

• Before performing any service operation, always shut off the air supply and release the pressure of the medium, i.e. let the grease out so

that the pressure decreases. When storing the pump assembly without the bucket, cover the Filter Tube (57) with Filter Cap (62).

• Be careful not to damage any parts when dismantling. While removing shafts which do not have key flats, use a Pipe wrench, Polygrip

wrench or the like. The easiest way to remove such a shaft is to grip it in a vice with aluminium or copper jaws, clamp the shaft in a

hand-drill chuck and then turn the chuck by hand.

• Be careful when fitting O-rings and seals. Always lubricate them with grease before fitting. They must never be threaded over sharp

edges when being fitted. Lubricate all moving parts with synthetic grease. Apply minor locking fluid on all threaded joints.

• When troubleshooting, be on a lookout for dirt in valves / ball seats, scratches in sealing surfaces & damaged O-rings / seals / gaskets.

Pumping Section Kit Replacement (Refer to Table 5 - Page 17)

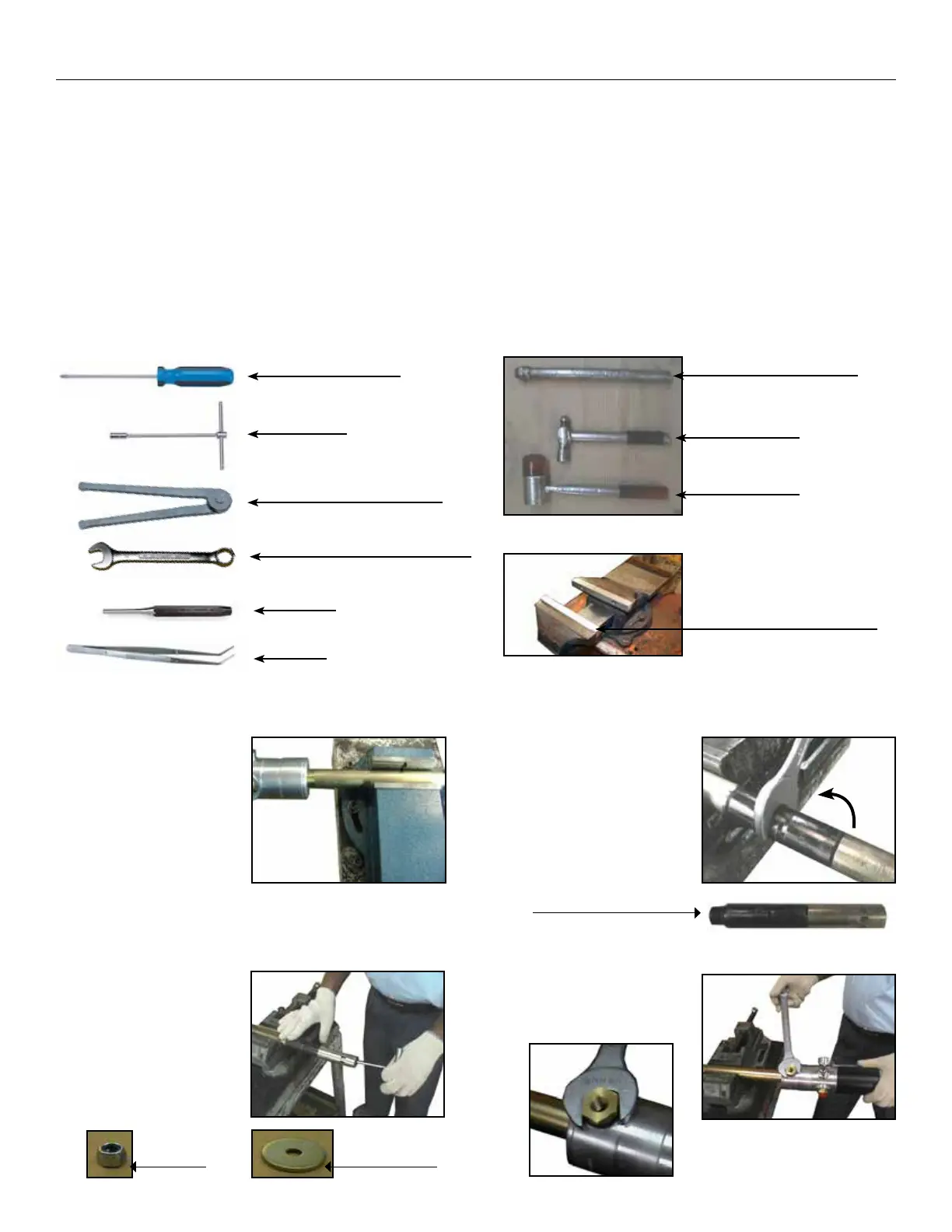

1. Hold Barrel (63) in a soft-

jaw vice. Pull out Filter

Cap (62) by hand.

2. Unscrew Nyloc Nut (61)

using T-handle (size 10

mm) & also remove

Piston Washer (60) from

the end of Filter Tube

(57).

3. Unscrew Top Coupler (52)

using wrench (size 28

mm) on the given flats.

Remove lower coupler

assembly.

4. Remove the outlet adapter

(35) using wrench (size 25

mm).

Lower Coupler Assembly

Nyloc Nut Piston Washer

Combination Wrench

Size 10, 14, 21, 25, 28 & 32 mm

Adjustable Caliper Wrench

Ball Pein Hammer

Plastic Mallet

A Soft - Jaw vice

(Aluminum or Copper Jaws)

Pin Punch

2 mm

Tweezer

T- Handle

Size 10 mm

1/2” Male Threaded Pipe

Phillips Screwdriver

Loading...

Loading...