English (GB)

5

6. Mechanical installation

Before installing the pump, check that the pump type

and parts are as ordered.

6.1 Installation of pump

Install the pump on a plane surface using the

mounting holes in the motor base plate and a

minimum of four bolts. Tighten each of the four bolts

to a torque of 10 Nm.

Install the pump so that air locks are avoided in the

pump housing and pipework.

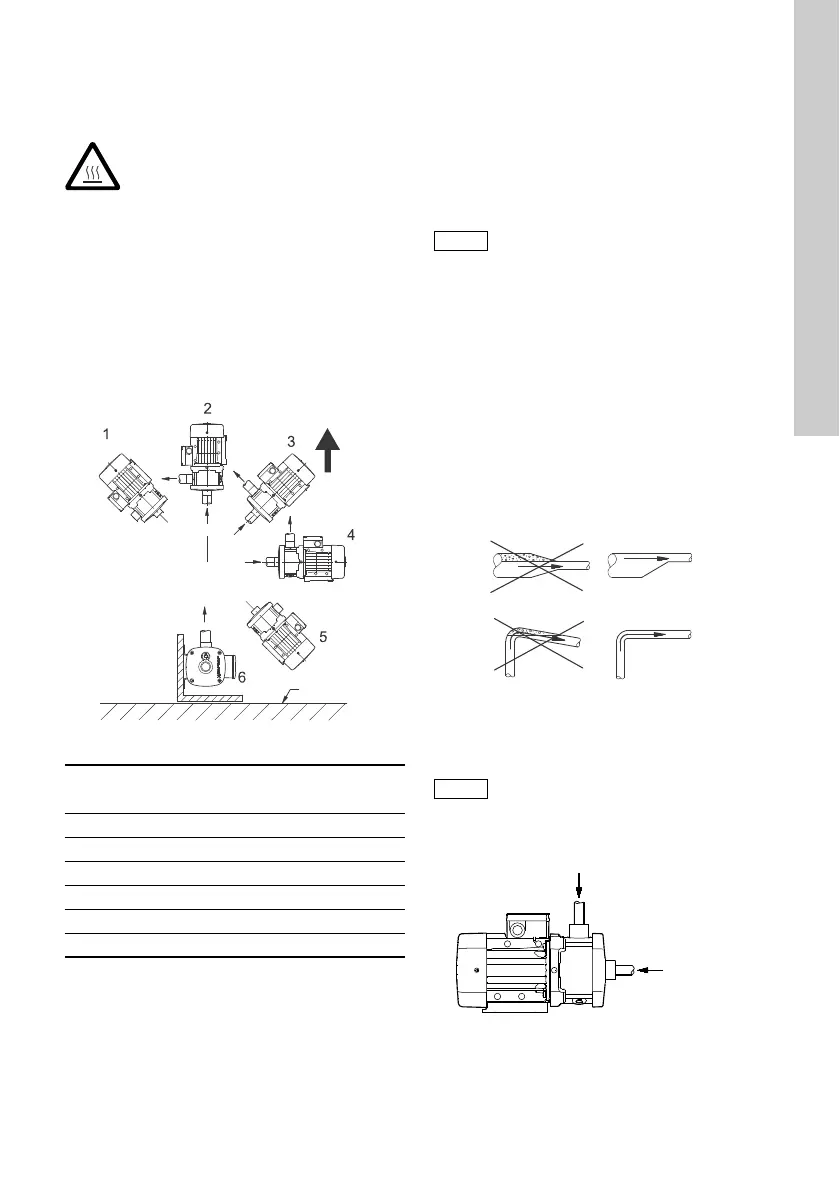

Figure 1 and the table below show the permissible

pump positions.

Fig. 1 Pump positions

● Mounting in this position is allowed.

Install the pump so that inspection, maintenance and

service can easily be performed.

Install the pump in a well-ventilated location.

6.2 Pipework

We recommend that you fit isolating valves on either

side of the pump. It is thus not necessary to drain the

system if the pump needs service.

If the pump is installed above the liquid level, a

non-return valve must be fitted in the suction pipe

below the liquid level. See fig. 4.

If the pump is to be used for pumping rainwater or

well water, we recommend that you fit a filter to the

inlet of the suction pipe.

The pump must not be stressed by the pipework.

Install the pipes according to the design

requirements given in EN ISO 13480-3:2012.

Tolerances must comply with EN ISO 13920:1996,

class C.

The pipework must be correctly sized taking due

account of the pump inlet pressure.

Install the pipes so that air locks are avoided,

especially on the suction side of the pump. See fig.

2.

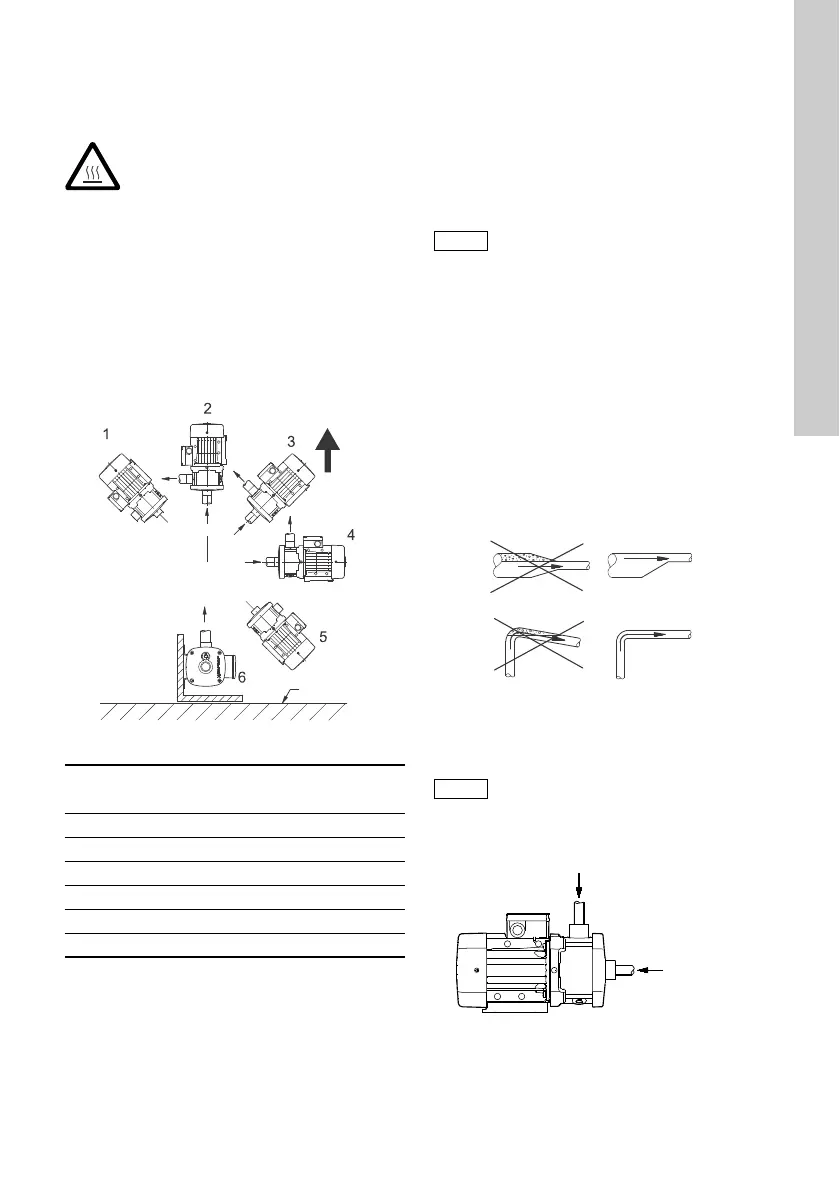

Fig. 2 Pipework

6.2.1 Pipe connection (non-self-priming pumps)

Fig. 3 Suction and discharge ports

Warning

When pumping hot or cold liquids, make

sure that persons cannot accidentally

come into contact with hot or cold

surfaces.

TM05 6389 4712

Pump

position

Non-self-priming

pumps

Self-priming

pumps

1- -

2 -

3 -

4

5- -

6

Self-priming pumps:

We recommend an opening pressure of

the non-return valve which is lower than

0.05 bar. Otherwise the additional

resistance will reduce the suction

capability of the pump.

TM04 0338 0608

Take care not to damage the pump when

connecting the suction and discharge

pipes.

Torque: 50-60 Nm. The stated torque must

not be exceeded.

TM04 0358 1008

Discharge port

Suction port

Loading...

Loading...