English (GB)

6

6.2.2 Pipe connection (self-priming pumps)

The pump must be installed correctly to ensure that it

can self-prime.

Take the following precautions:

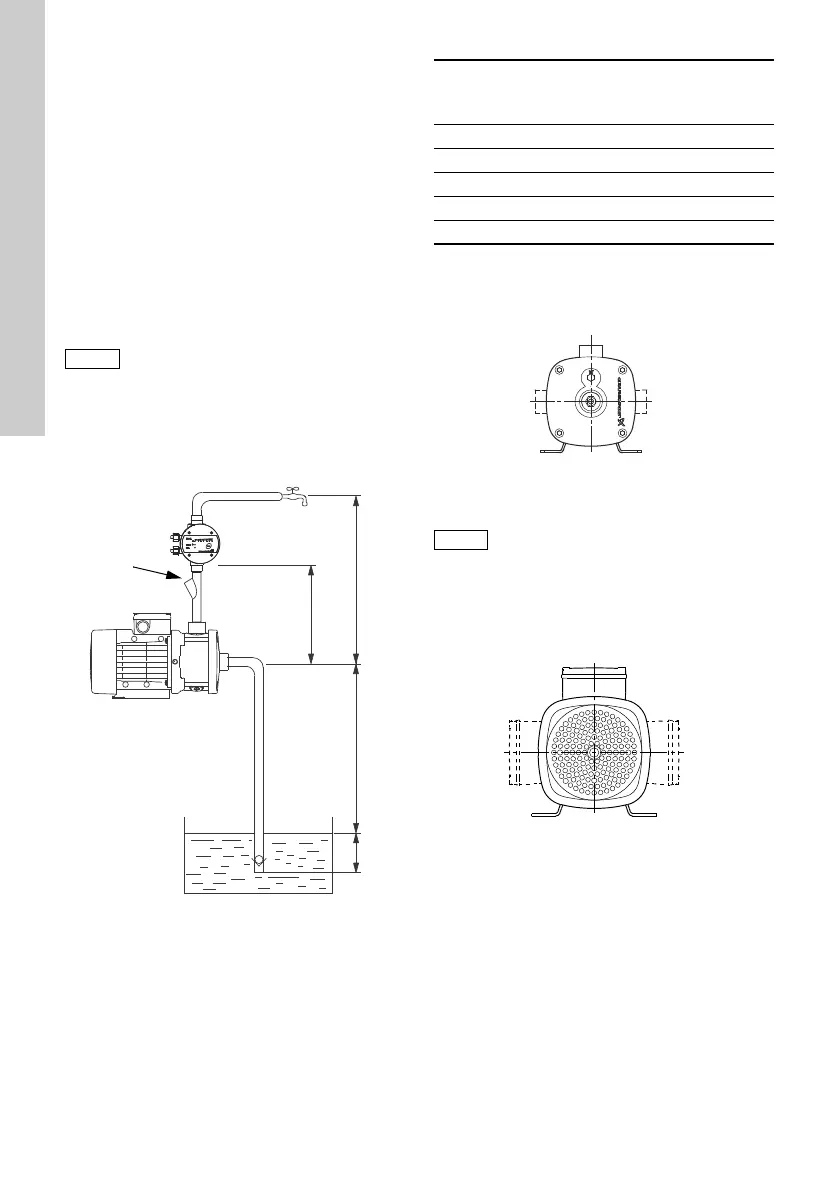

See fig. 4.

• The minimum height from the centre of the

suction port to the first tapping point (H

1

) must be

observed.

If a pressure manager is installed in the system,

H

1

is the height from the centre of the pump

suction port to the pressure manager.

Minimum heights appear from the table below.

• The suction pipe must be at least 0.5 metres

below the liquid level (H

3

).

We recommend that you install a filling plug in the

discharge pipe. This facilitates liquid filling before

startup. See fig. 4, pos. A.

Fig. 4 Recommended pipework for a

self-priming pump

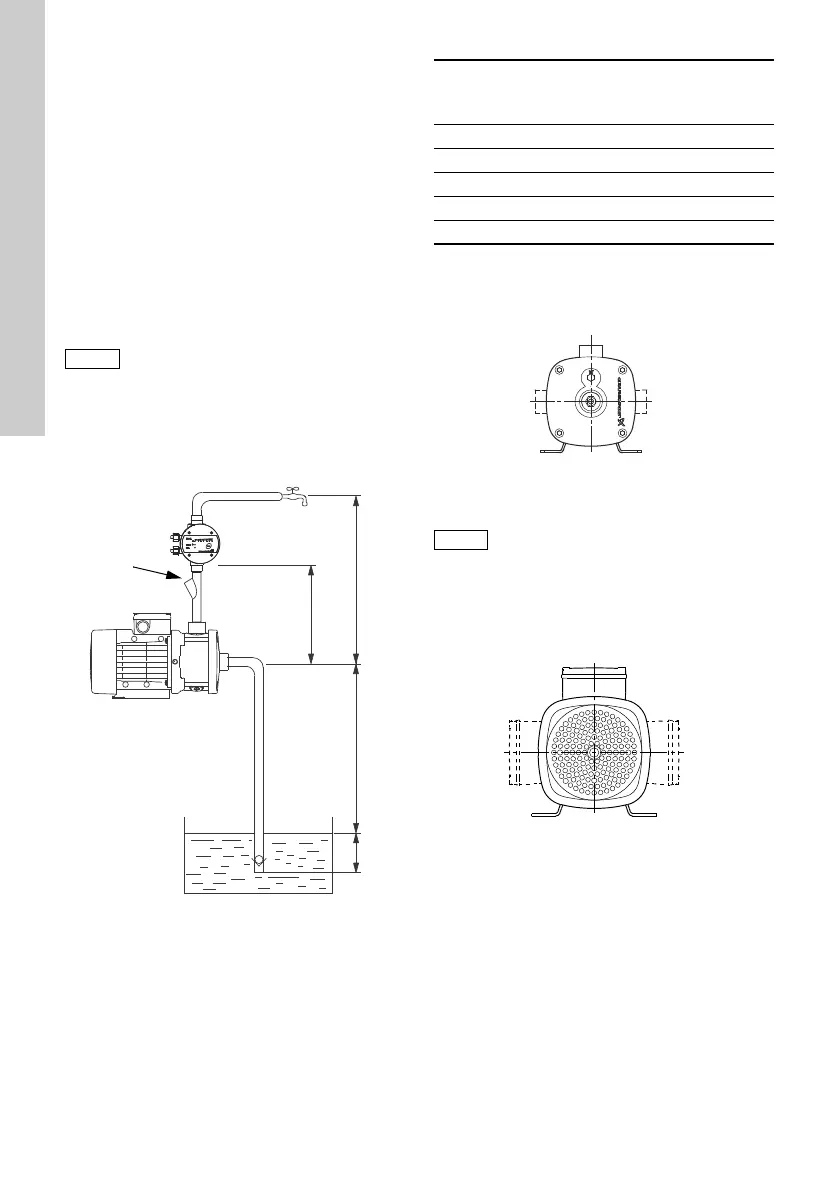

6.3 Alternative connection positions

The pump is available with various connection

positions on special request. See fig. 5.

Fig. 5 Alternative connection positions

6.4 Terminal box positions

The pump is available with various terminal box

positions on special request. See fig. 6.

Fig. 6 Terminal box positions

For optimum suction capability, the pump

must be located near the well or tank to

ensure that the suction pipe is as short as

possible. This will reduce the self-priming

time, especially in the case of a high

suction lift.

TM05 8415 2313

Suction lift

(H

2

)

[m]

Minimum height

(H

1

)

[m]

40.2

50.35

60.5

70.6

80.7

TM03 8709 1008

Self-priming pumps:

These pumps are only available with the

discharge port pointing upwards, i.e. in the

same direction as the filling hole.

TM04 0357 1008

Loading...

Loading...