24

15.720017-V6.0

DMX model 226 en

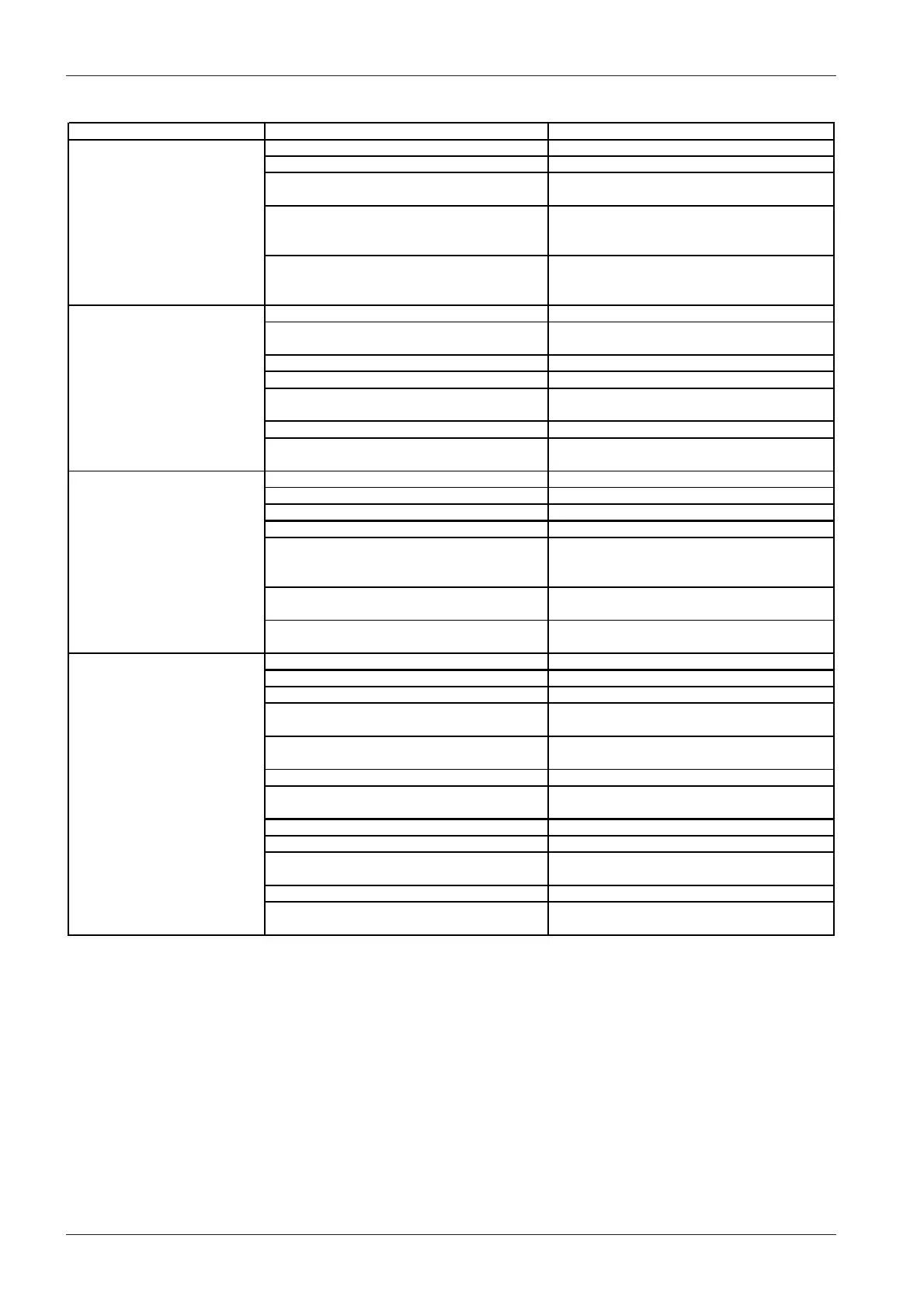

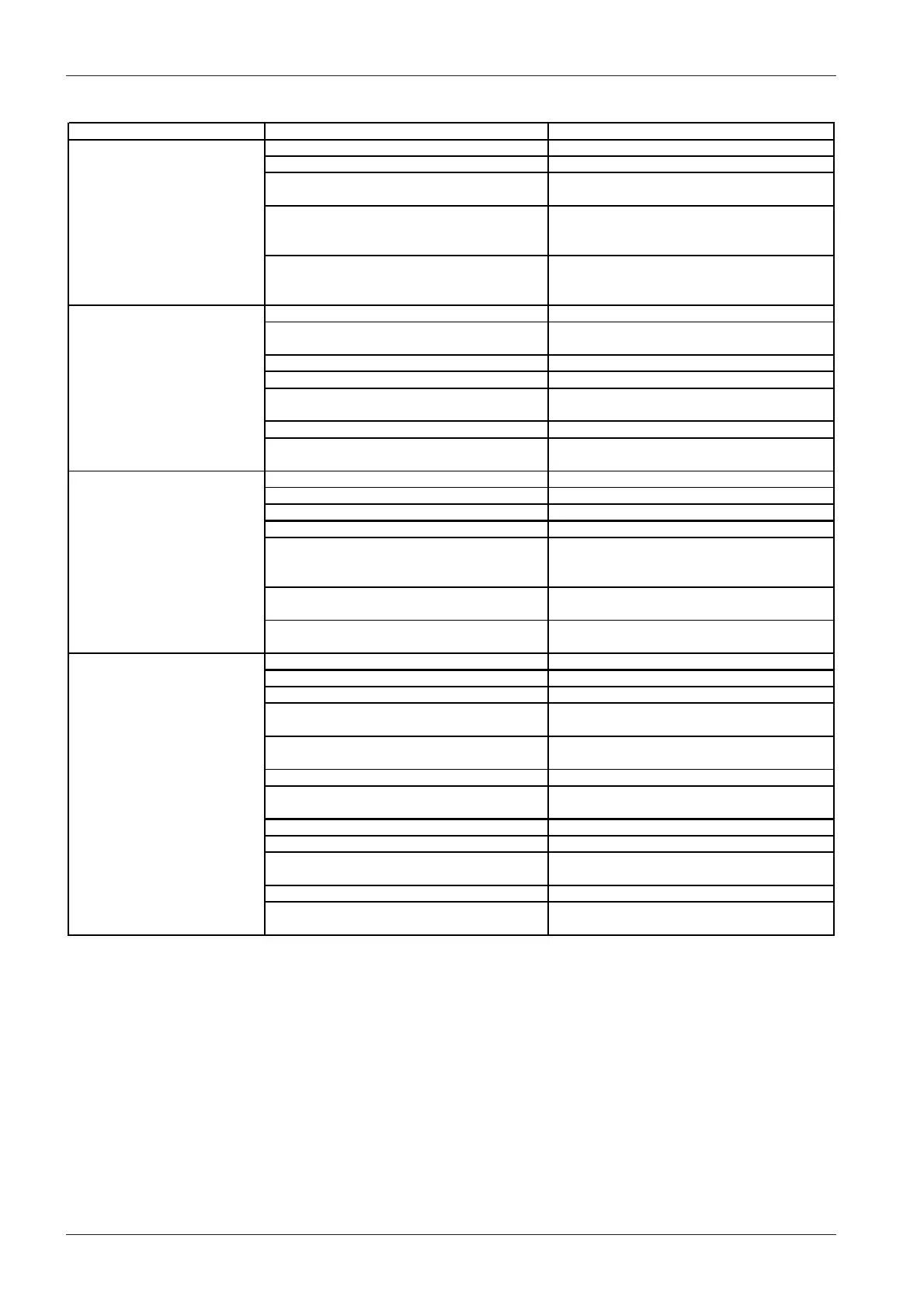

6.5 Possible Failures

Failure Cause Correction

Not connected to mains Connect the mains line

Wron

mains volta

e Re

lace the dosin

um

Electrical failure Return the dosing pump to the works for repair

The empty indication has responded. The

empty indication symbol blinks in the display

Remove the cause

The diaphragm breakage indication has

responded. ERROR and MBS are blinking in

the dis

la

.

Replace the diaphragm.

Leak

suction line Exchan

e or seal the suction line

Cross-section of the suction line too narrow or

or suction line too lon

Check with specification of Grundfos

Clo

ed suction line Rinse or re

lace the suction line

Foot valve covered b

sediment Sus

end the suction line at a hi

her

osition

Buckled suction line Lay the suction line correctly, check for

dama

e

Cr

stalline de

osits in the valves Clean the valves

Diaphragm broken or diaphragm tappet torn

out

Exchange the diaphragm

ir in the suction line and dosin

head Wait, until the

um

has deaerated

Stroke ad

ustment set to zero Turn the ad

ustment knob in the "+" direction

Medium too viscous or densit

too hi

h Check the installation

Cr

stalline de

osits in the valves Clean the valves

Valves not correctly assembled Assemble the valve inside parts in the right

order and check or possibly correct the flow

direction

Injection point blocked Check and possibly correct the flow direction,

or remove the occlusion

Inexpert installation of lines and peripheral

e

ui

ment

Check for perviousness and correct installation

Dosin

head not full

deaerated Re

eat deaeration

De

assin

medium Check the installation

Valves

artiall

soiled or incrusted Clean the valves

Zero-point misadjusted Adjust the zero-point to the actual back

ressure

Fluctuations of back pressure Application of a pressure retention valve and a

ulsation dam

er

Fluctuations of suction hei

ht Kee

the suction level constant

Siphon effect (admission pressure higher than

back

ressure

Install a pressure retention valve

Leak

or

orous suction line or

ressure line Re

lace the suction line or

ressure line

Parts in contact with media not resistant Re

lace with resistant materials

Dosing diaphragm worn out (incipient tears) Replace the diaphragm, also observe

maintenance instructions

Fluctuations of mains volta

e Decrease the back

ressure of the

um

Variation of the dosing medium (density,

viscosit

Examine the concentration, possibly employ an

a

itator

Dosing output of the pump

inaccurate

Dosing pump does not suck in

Dosing pump does not run

Dosing pump does not dose

Loading...

Loading...