18 15.720023-V3.0

DMX model 227

14

p

1

p

2

p

2

- p

1

1 bar

>

_

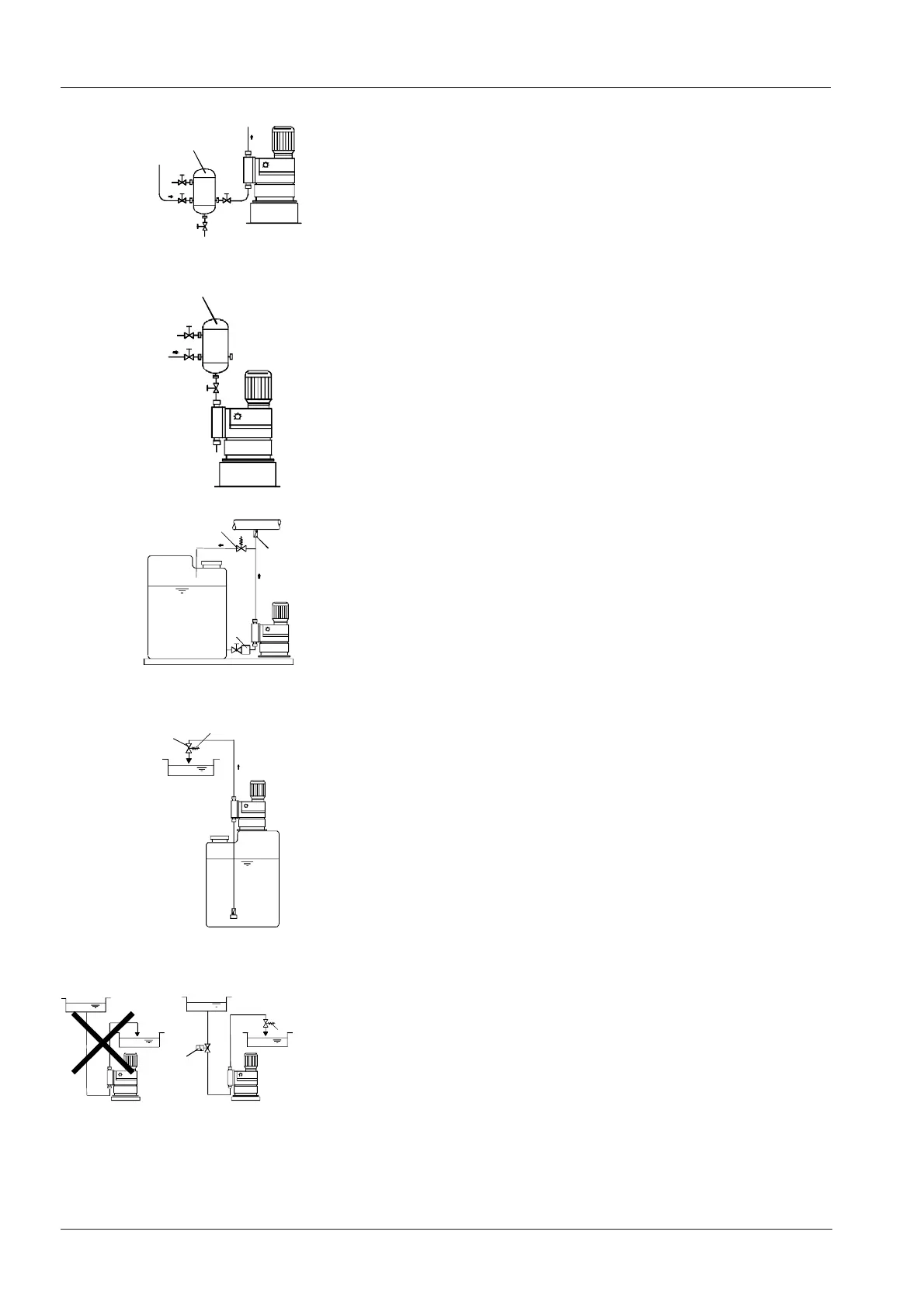

● Note for pressure side installation:

to protect the piping use pulsations damper (8) for rigid piping longer than

3m and tubing longer than 5m.

8

6

10

p

4

● In dosing systems that require a long suction line:

Provide a properly dimensioned pulsation damper (4) directly in front of the

suction valve of the dosing pump.

● For outgassing and viscous media: flooded suction

● To protect the dosing pump and the pressure line agains: excessive

development of pressure: Install an overflow valve (6) in the pressure line.

10 Injection unit

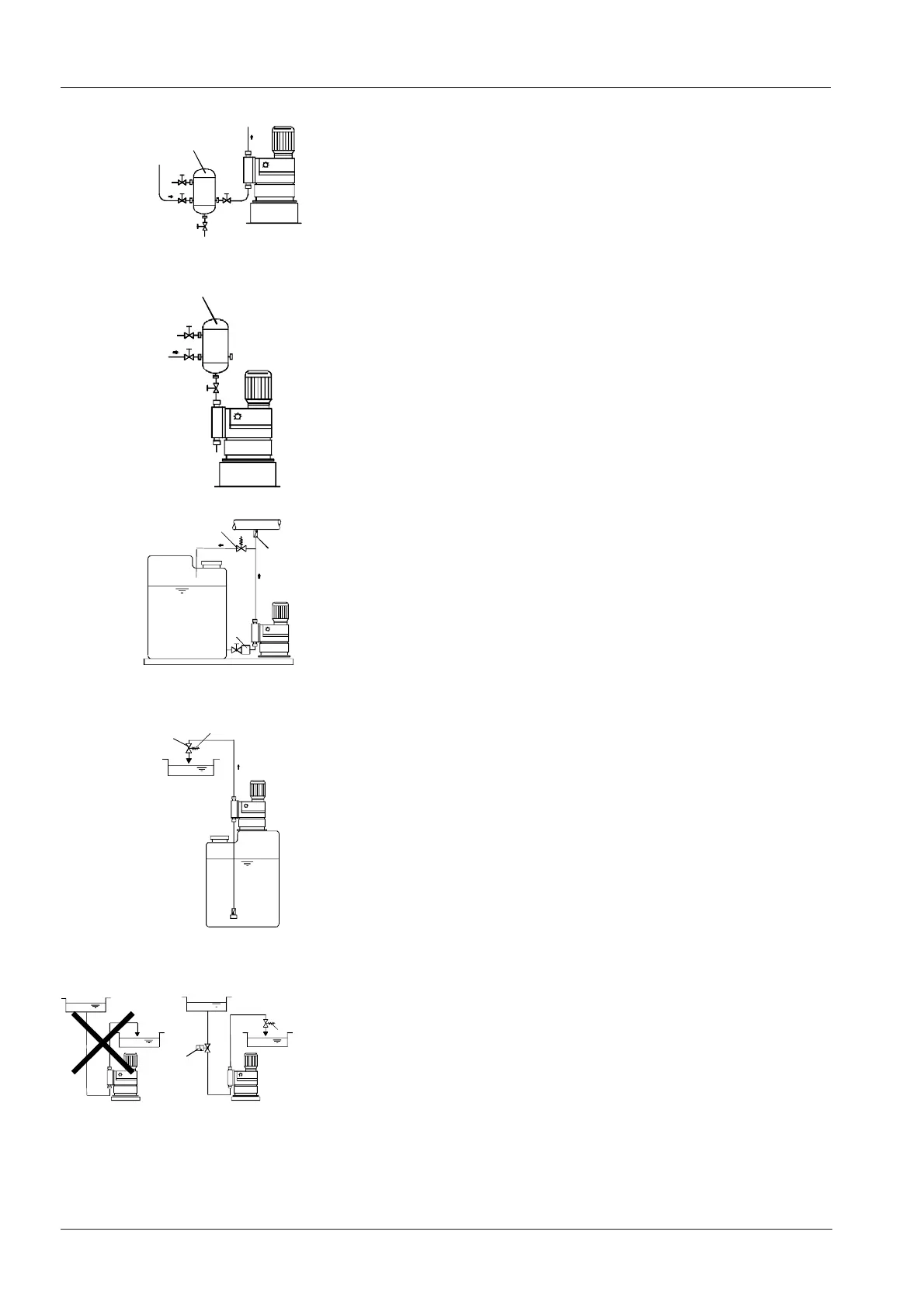

● With open outflow of the dosing medium or a counterpressure below 1 bar:

Install a pressure retention valve (7) directly in front of the outlet or the

injection unit.

A positive pressure difference of at least 1 bar has to exist between the

counterpressure at the injection point and the pressure of the dosing medi-

um at the suction valve of the dosing pump. If this cannot be guaranteed:

• Install a pressure retention valve (7) in the pressure line

To avoid the siphon effect:

● Install a pressure retention valve in the dosing line and, if necessary, a

solenoid valve (14) in the suction line.

7

p

≥

2 bar

Loading...

Loading...