17V3.0

DMX model 227

4 Installation

4.1 Installation Information

1

2

3

4

5

6

7

9

10

8

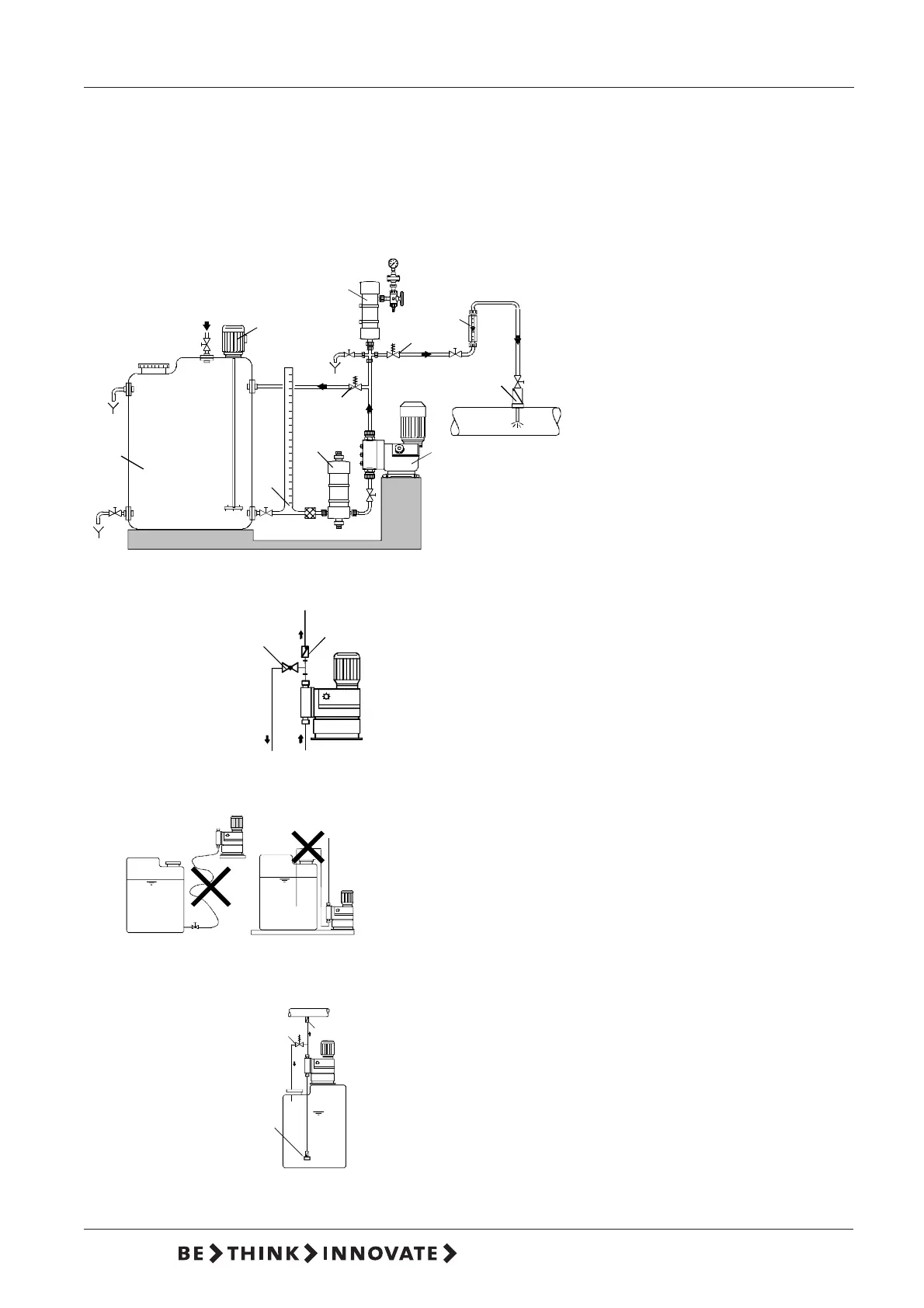

Picture of optimal installation:

1 Dosing tank 502

2 Electric agitator 509

3 Extraction device 521

4 Suction pulsation damper 516

5 Dosing pump

6 Overflow valve 525

7 Pressure retention valve 525

8 Pulsation damper 517

9 Measuring glass

10 Injection unit 522

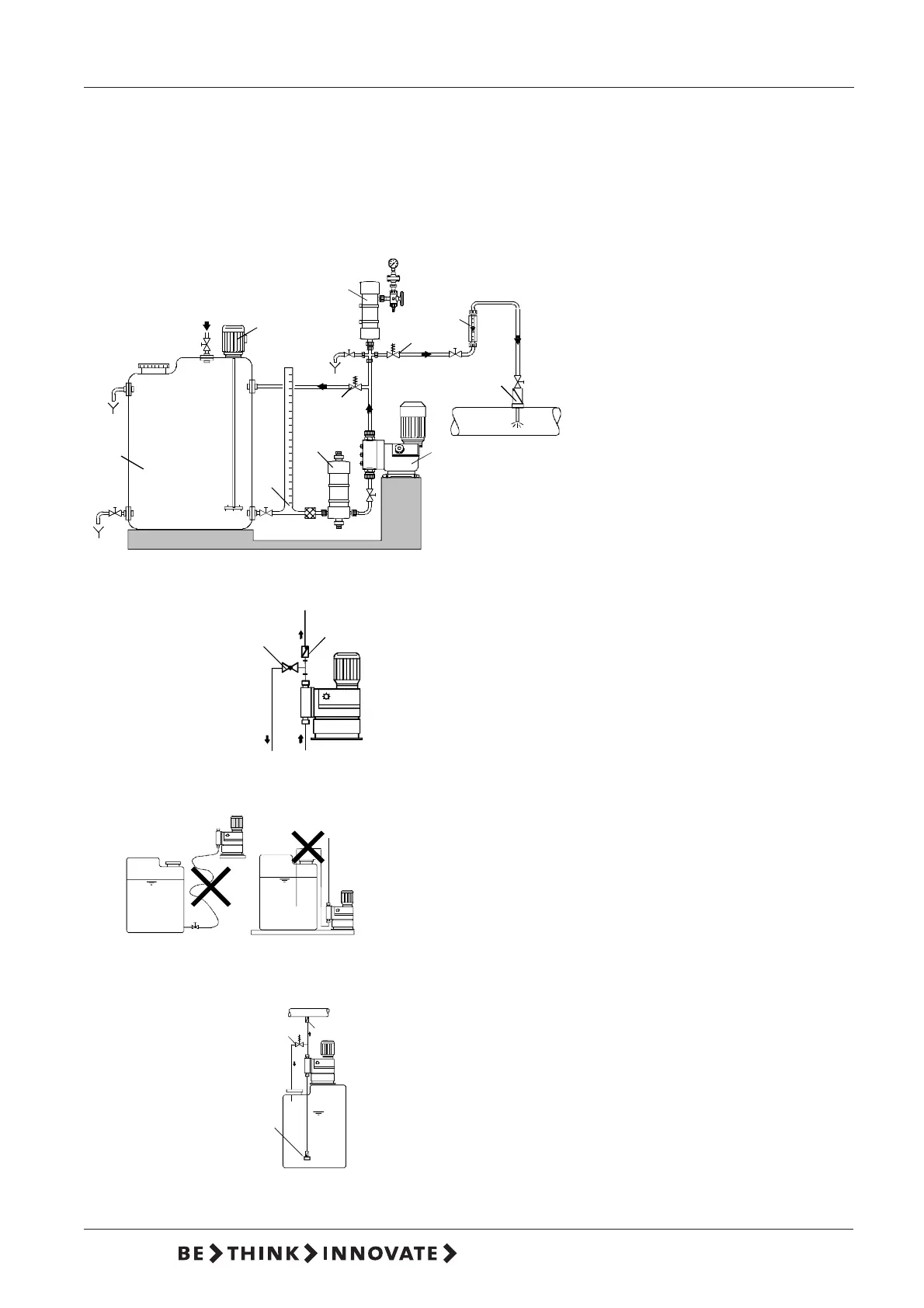

p

10

6

13

11

12

For easy deaeration of the pump:

● Install a ball valve (11) with bypass line (back to the dosing tank)

immediately behind the pressure valve

In case of long pressure lines:

● Install a check-back valve (12) into the dosing line.

● Keep the suction line as short as possible, avoid a tangled suction

line

• If necessary, use swept bends instead of elbows.

● Always lay the suction line rising to the suction valve of the dosing

pump.

• Avoid loops which cause air bubbles.

● For non-degassing media with viscosity similar to water, the pump

can be mounted onto the tank (observe the admissible suction

height). Preferably flooded suction.

For dosing media which tend to sedimentation:

● Install a suction line with filter (13) in a way ensuring that the suction

valve remains several centimetres a bove the botton of the tank.

6 Overflow valve

10 Injection unit

Loading...

Loading...