9

Note: Float switches of the same type as Grundfos product

number 96003332 or 96003695, i.e. float switches with

gold-plated contacts suitable for low voltages and currents (40 V/

100 mA), must be used. All EEx-approved float switches are also

suitable.

The float switches must be connected as NO contacts, i.e. brown

and black leads, when float switches, Grundfos product number

96003332 or 96003695, are used.

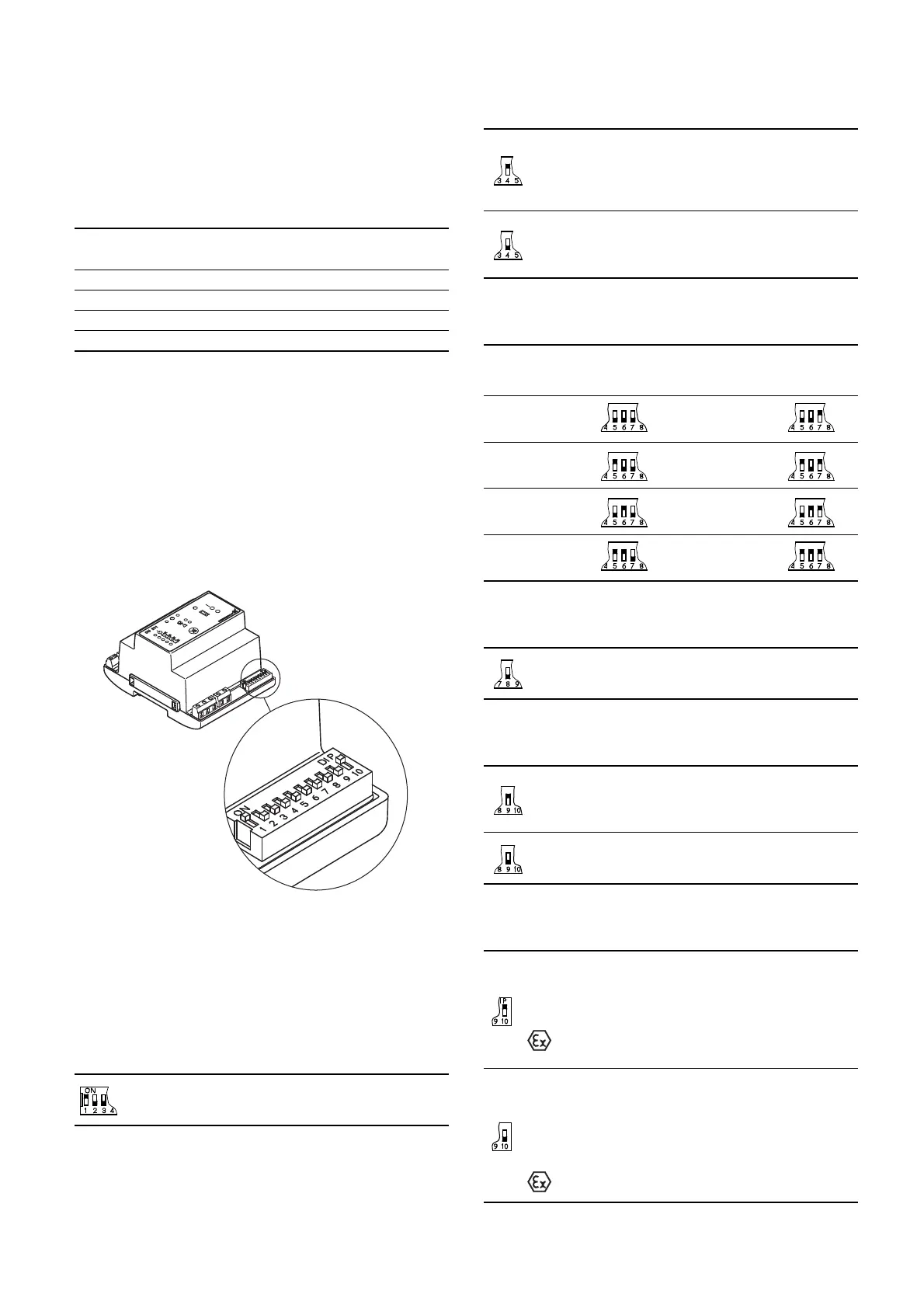

Key to the symbols in fig. B1 on page 25 and fig. B2 on

page 26:

4.2 Setting

Parallel operation with 4 float switches, pages 25 and 26.

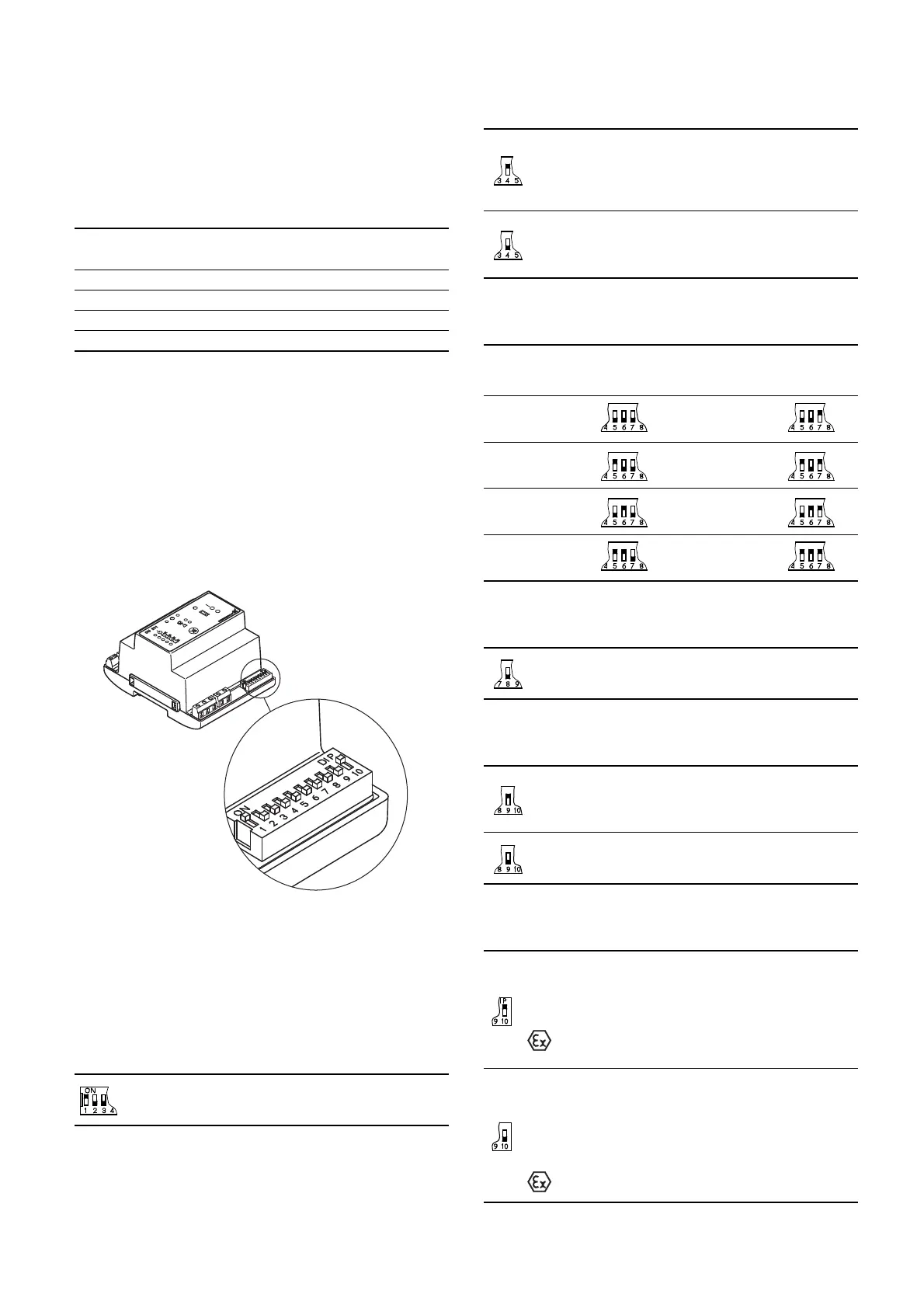

The module CU 212 has a 10-pole DIP switch in the bottom right

corner, see fig. 5.

Note: The controller must be off circuit to ensure the correct

configuration during start-up after change of the DIP switch

setting.

The DIP switch setting offers the following possibilities:

• selection of starting delay and automatic test run (switch 4),

• setting of stop delay (switches 5, 6 and 7),

• selection of automatic alarm resetting (switch 9),

• selection of automatic restarting (switch 10).

Fig. 5

Set the DIP switch as shown in fig. 5. Each individual switch (1 to

10) of the DIP switch can be set to position OFF or ON.

Note: The DIP switch must not be set to other switch

combinations than those described in this section.

Set the switches 1 to 10 as follows:

•Switches 1, 2 and 3, application type:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

•Switch 4, starting delay and automatic test run

(only in the case of battery back-up):

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

• Switches 5, 6 and 7, stop delay:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

•Switch 8:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

•Switch 9, automatic alarm resetting:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

•Switch 10, automatic restarting:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

Pos. Description

Terminal

number

1 Float switch for common stop. 11-12

2 Float switch for start of the first pump. 21-22

3 Float switch for start of the next pump. 31-32

4 Float switch for high-level alarm. 41-42

TM04 2341 2308

This setting determines the actual application type

(parallel operation with 4 float switches, pages 25 and

26).

At this setting, the start-up is delayed within the range

from 0 to 255 sec. (random) after the electricity supply

has been switched on when the liquid level is

sufficiently high.

Automatic test run carried out every 24 hours.

After the electricity has been switched on, the pump will

start immediately when the liquid level is sufficiently

high.

No automatic test run.

The stop delay is the time from the stop signal is given until the

pump is stopped.

It must be ensured that the pump is not running dry.

0 sec. 60 sec.

15 sec. 90 sec.

30 sec. 120 sec.

45 sec. 180 sec.

Switch 8 has no function in connection with the actual

application (parallel operation with 4 float switches,

pages 25 and 26), but this setting must be maintained!

This setting ensures automatic resetting of alarm

signals to external alarm devices and the built-in

buzzer. However, an alarm signal will only be reset if

the cause of the fault no longer exists.

At this setting, the alarm signal must be reset manually

by means of the reset button (the reset button is

described in section 4.5).

This setting enables automatic restarting after the PTC

resistance/thermal switch of the motor has cut out the

pump. Restarting will not be carried out until the motor

has cooled to normal temperature.

When the pumps connected are used in explosion

hazard areas, switch 10 must not be in this

position!

At this setting, the pump must be restarted manually after

the PTC resistance/thermal switch of the motor has cut

out the pump. To restart the pump, push the ON-OFF-

AUTO selector switch into position OFF for a short period

(the ON-OFF-AUTO selector switch is described in

section 4.5).

When the pumps connected are used in explosion

hazard areas, switch 10 must be in this position!

Loading...

Loading...