English (US)

10

5.3 Motor direction of rotation

After the product has been wired and checked to ensure that all

components in the system, such as disconnect devices, magnetic

starters, pilot devices and motors, are properly connected, check

the motor direction of rotation as follows:

• For three-phase products only, momentarily energize the

motor to ensure that the direction of rotation is correct as

indicated by the arrow cast into the pump housing.

If direction of rotation is incorrect, interchange two wires at the

motor starter terminals T1 and T2.

5.4 Starting the pump

1. Install a coupling guard on coupled products.

2. Fully open the gate valve (if any) in the inlet line, and close

the gate valve in the outlet line.

3. Fill the inlet line with liquid and completely prime the pump.

4. Start the pump.

5. Immediately make a visual check of the pump and inlet pipe

for pressure leaks.

6. Immediately after the pump has reached full operating speed,

slowly open the outlet gate valve until complete system flow is

achieved.

7. Check the outlet pipe for pressure leaks.

8. If the pump is fitted with pressure gauges, open gauge cocks

and record pressure readings for future reference. Verify that

the pump is performing in accordance with the parameters

specified in the performance curves.

9. Check and record voltage, amperage per phase, and

kilowatts, if a wattmeter is available.

5.5 Voltage and frequency variation

The motor will operate satisfactorily under the following voltage

and frequency variations, but not necessarily in accordance with

the standards established for operation under rated conditions:

• The voltage variation must not exceed 10 % above or below

the rating specified on the motor nameplate.

• The frequency variation must not exceed 5 % above or below

the motor rating.

• The sum of the voltage and frequency variations must not

exceed 10 % above or below the motor rating, provided the

frequency variation does not exceed 5 %.

6. Storing and handling the product

See sections 3.3 Temporary storage after delivery, 9.2 Short-time

shutdown and 9.3 Long-term shutdown.

7. Product introduction

7.1 Applications

We recommend the L pumps for these applications:

• commercial and industrial cooling systems

– pumping both primary and secondary cooling water

• condenser water systems

• district cooling systems

• water distribution systems

• irrigation systems.

7.2 Pumped liquids

Clean, thin, non-aggressive liquids, not containing solid particles

or fibers. Do not pump liquids that will attack the pump materials

chemically.

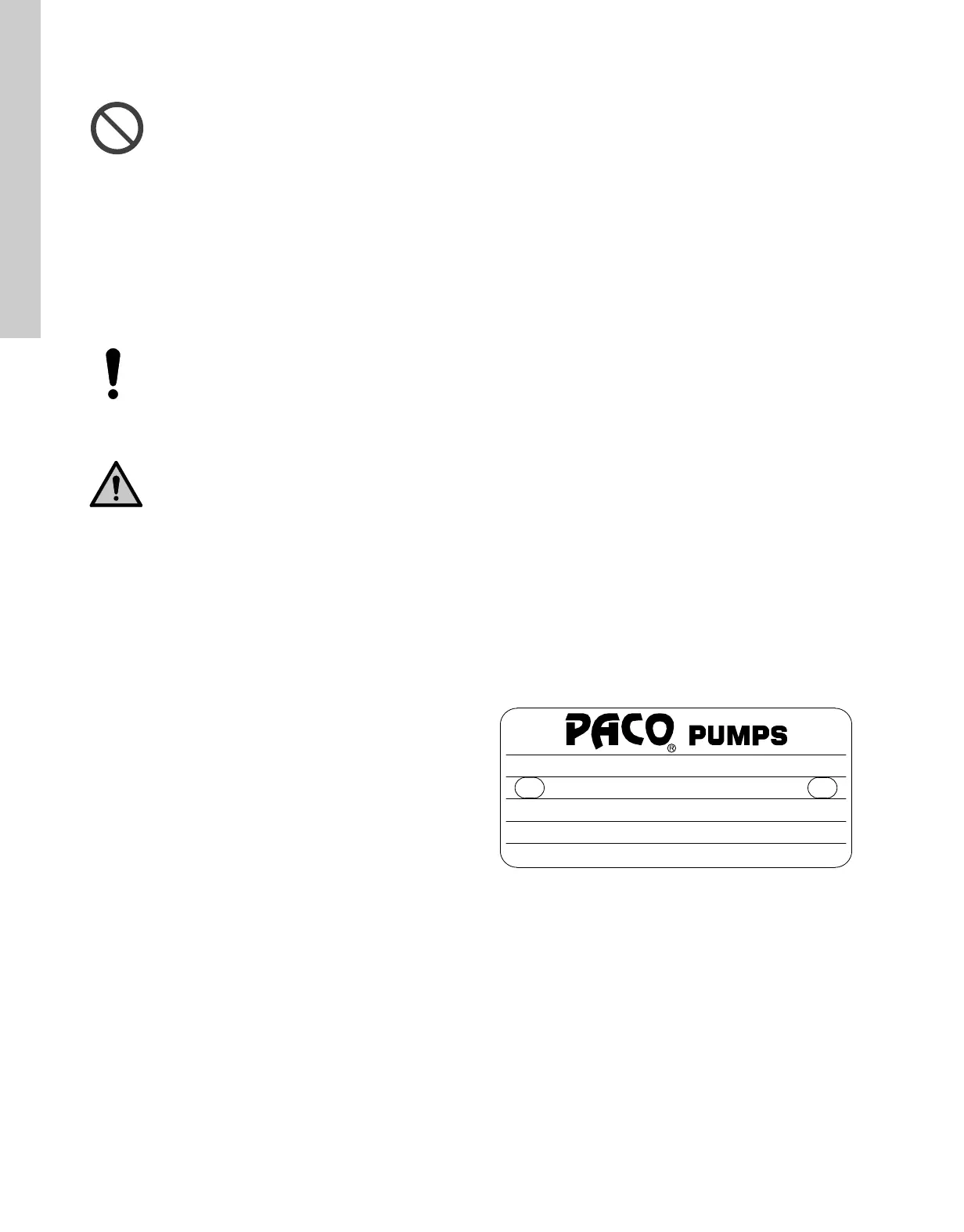

7.3 Pump identification

All pumps are identified by catalog and serial numbers. These

numbers are stamped on the pump nameplate, as shown in fig. 6,

affixed to the pump housing. Refer to these numbers in all

correspondence with Grundfos.

Fig. 6 Nameplate

Never check the motor direction of rotation unless

the pump and motor couplings have been

disconnected and physically separated. Failure to

follow this instruction can result in serious damage

to the pump and the motor if the direction of rotation

is wrong.

The pumps must not be operated while dry.

Use extreme caution that motors are energized only

momentarily to determine proper direction of rotation.

DANGER

Moving machine parts

Death or serious personal injury.

- Mount an approved coupling guard before

operating the product.

TM06 6128 0616

CAT#: 10-20707-130101-1741

STOCK#:

SER#: 97R12345

GPM: 234

TDH: 88

MFD BY GRUNDFOS CBS INC 34014412

IMP

DIA

5.11

:

LC_LCV_LF_LCS_1 language_US Eng.book Page 10 Thursday, August 24, 2017 4:08 PM

Loading...

Loading...