English (US)

12

Oil lubrication

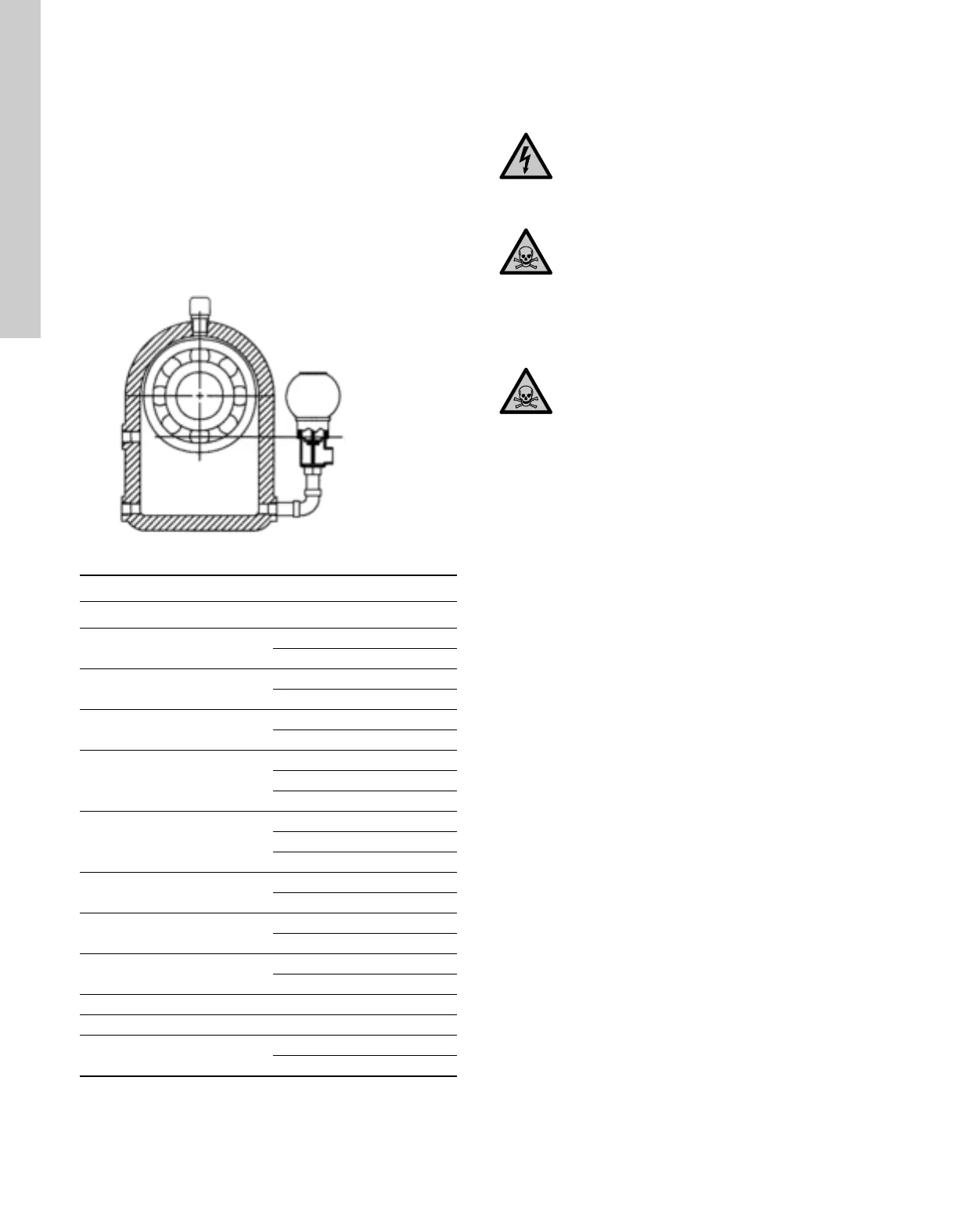

LF pumps with oil lubricated bearings are fitted with a transparent

reservoir, a constant-level oiler, that maintains the oil level about

the centerline of the bearing. See fig. 7.

• Follow a regular oil maintenance program. When necessary,

renew the oil supply in the reservoir of the constant-level oiler.

• Change the oil after the first 200 hours of operation. To change

the oil, remove the drain plug at the bottom of the bearing

cover and the filler plug, that also acts as a vent plug, at the

top of the bearing frame. After draining the oil, replace the

drain plug and refill the reservoir with an oil from the table List

of acceptable oil lubricants on page 12. After the first oil

change, the oil must be changed again at 2000 hours and then

at intervals of 8000 hours or once a year, thereafter.

Fig. 7 Oil lubrication

8.3 Disassembling the pump

8.3.1 Preparations before disassembling the pump

Complete disassembly instructions are outlined below. Proceed

only as far as required to perform the maintenance work needed.

1. Switch off the power supply.

2. Drain the system.

3. Flush the system, if necessary.

4. For close-coupled pumps: Remove the motor fixation bolts.

TM05 4793 2613

List of acceptable oil lubricants

Lubricant manufacturer Bearing oil brand name

Aral Refining Co.

Aral Oil CMU

Aral Oil TU 518

British Petroleum Co.

BP Energol

TH 100-HB

Calypsol Oil Co.

Calypsol Bison Oil

SR 25 or SR 36

Standard Oil Co.

Chevron

Hydraulic Oil 11

Circulating Oil 45

Esso Corp

Esso-Mar 25

Teresso 47

Esstic 50

Fina Oil Co.

Fina Hydran 34

Fina Cirkan 32

Gulf Refining Co.

Gulf Harmony 47

Gulf Paramount 45

Socony Mobil Oil Co.

Vac hlp 25

Mobulix D.T.E. 25

Shell Oil Co. Shell Tellus Oil 29

Sundco Oil Co. Sunvis 821

The Texas Co.

Texaco Ursa Oil P 20

Dea Viscobil Sera 4

DANGER

Electric shock

Death or serious personal injury.

- Before starting any work on the product, make

sure that the power supply has been switched off

and that it cannot be accidentally switched on.

CAUTION

Toxic material

Minor or moderate personal injury.

- Wash down the pump before doing any work on it.

DANGER

Hot, caustic, flammable or toxic materials,

including vapors

Death or serious personal injury.

- Be extremely cautious when venting and/or

draining hazardous liquids.

Wear protective clothing when there are caustic,

corrosive, volatile, flammable, or hot liquids.

Do not breathe toxic vapors.

Do not allow sparks, open fire, or hot surfaces

near the equipment.

LC_LCV_LF_LCS_1 language_US Eng.book Page 12 Thursday, August 24, 2017 4:08 PM

Loading...

Loading...