2. Use dial indicator to check hub circumference and

end face. Adjust the hub alignment according to

the measurements. The deviation of hub

circumference and end face mustn't exceed 0.05

mm. For hub flange diameter bigger than 250 mm,

the maximum deviation is 0.08 mm. Reinstall the

hub if the deviation exceeds the limit. Refer to

section Tightening torques for spacer coupling.

3. Place the motor and the pump in working position

and measure the distance F between the two hub

surfaces of the motor and pump. Take four

readings along circumference with 90° interval

and calculate the average value. Adjust the

position of the motor and pump until the value of F

meets the dimension Ls in the assembly drawing,

Ls is the distance between pump shaft end and

motor shaft end. The deviation should be from 0

mm to 0.4 mm.

TM082166

4. Choose one of the following methods that suits

best for the installation:

a. Use professional aligning apparatus.

b. Use the dial indicator to measure the deviation

of the circumference and the end face.

Determine the location of shafts by analyzing

the measurements, and then adjust the shafts

based on the results. See section on Accepted

misalignment.

In order to improve the precision, use two dial

indicators that locate equidistant to axis to

measure the deviation of the end face.

TM082161

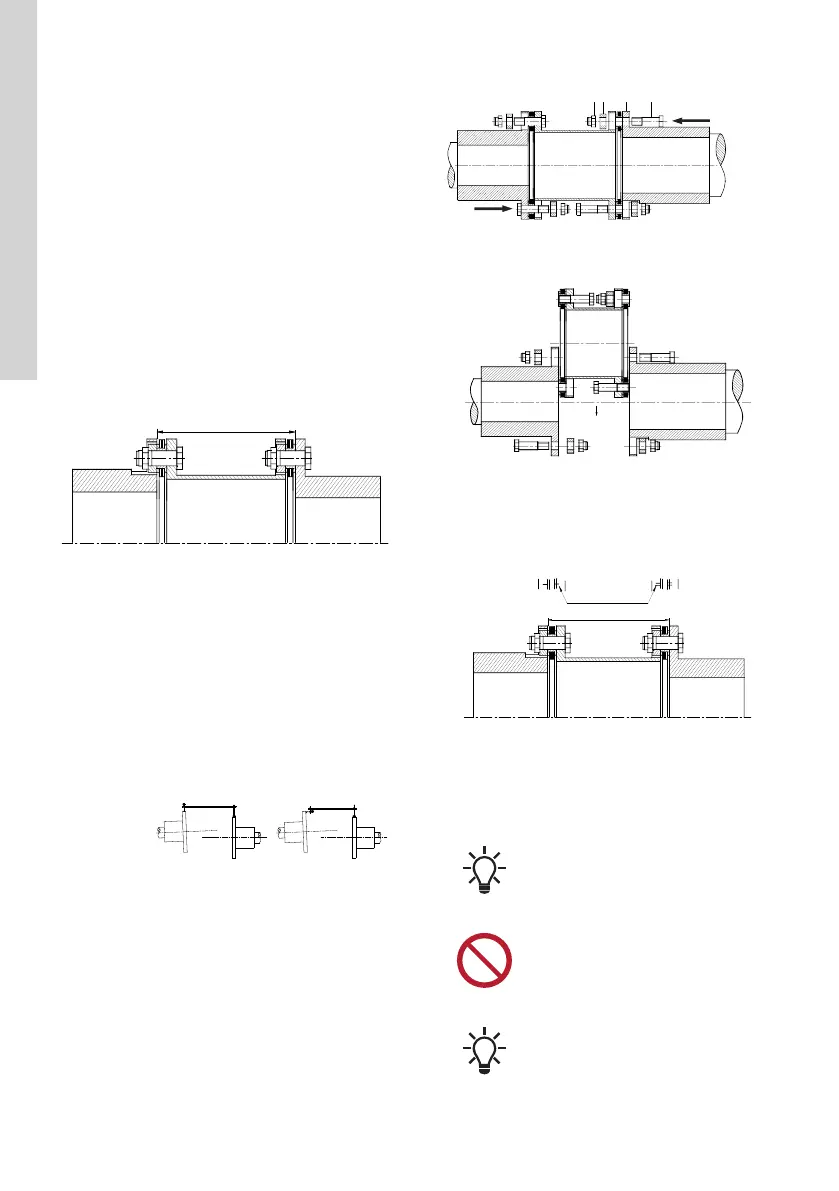

5. Place the disc packs and the spacer between the

hubs, tighten with bolts, sleeves and self-locking

nuts or slotted nuts. The hexagon bolts (2) must

be installed next to flanges (8). The sleeves (4)

and the nuts (3) must be installed next to each

other. Reversion is prohibited.Refer to the figure

below.

TM082160

• With short shafts distance, pre-install the bolts

into spacer and then perform the step above.

TM082159

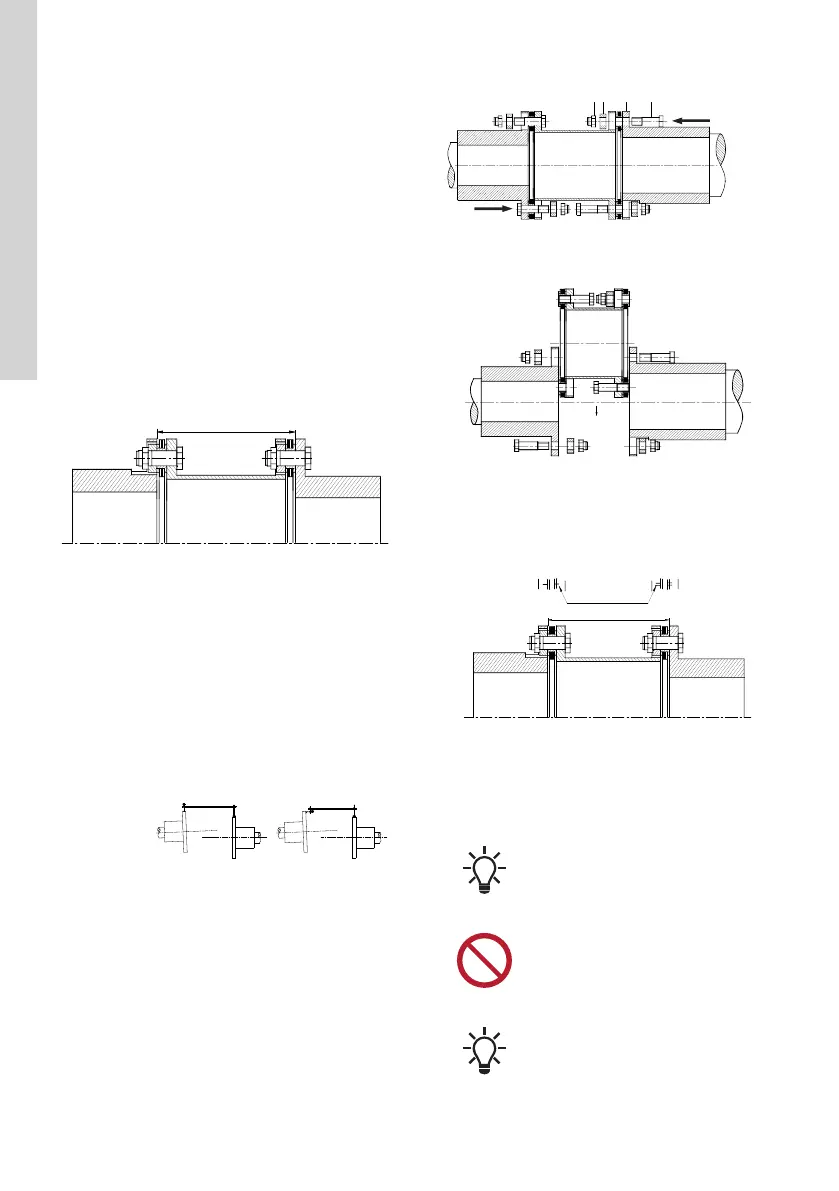

• The dynamically balanced coupling parts must

be installed according to the position mark (M)

on the coupling. Fasteners with the same

specification in the same set of coupling can

be replaced with each other.

TM082158

6. Tighten the nuts diagonally and evenly and make

sure the bolts won't rotate when tightening. Use

the torque wrench to achieve the required

tightening torque at least in two rounds. See

section on Torque.

Apply a little grease to the nut thread

before the installation.

Self-locking nuts can be used

repeatedly. But if the nuts can be freely

tighten to bolts manually or the nuts

have defects, the users mustn't use

them.

For slotted nuts, insert a cotter pin to

secure and make sure it won't loosen

when operating.

10

English (GB)

Loading...

Loading...