3.2.5.1 Preliminary alignment

DANGER

Electric shock

Death or serious personal injury

‐ Before starting work on the pump,

make sure that the power supply has

been switched off and that it cannot be

accidentally switched on.

The pump and motor are pre-aligned on the base

frame from the factory. Some deformation of the base

frame may occur during transport, and it is therefore

essential to check alignment at the installation site

before final grouting.

Inaccurate alignment results in vibration and

excessive wear on the bearings, shaft and wear rings.

Carry out alignment of the motor only, as

pipe strain will occur if the pump is shifted.

If the coupling guard is installed, remove it before the

alignment. For align methods, see sections Aligning

the pump and motor with a straightedge ruler,

Aligning the pump and motor with a dial indicator and

Aligning the pump and motor with a laser equipment.

Related information

4.5.4 Tightening torques

4.5.1 Aligning the pump and motor with a

straightedge ruler

4.5.2 Aligning the pump and motor with a dial

indicator

4.5.3 Aligning the pump and motor with a laser

equipment

4.5.5 Pin coupling air-gap width S2

3.2.5.2

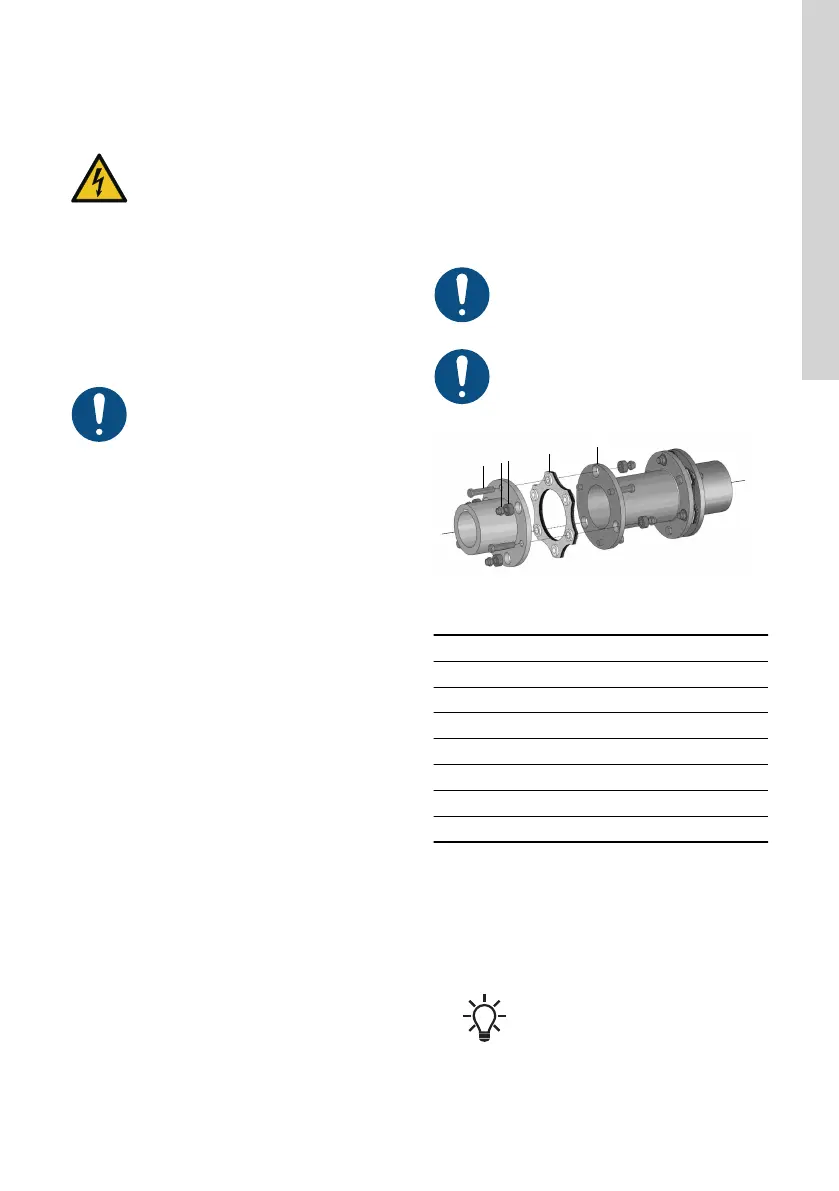

Spacer coupling installation

Preparation

• Check the spacer coupling for possible transport

damage and missing parts. Clean the spacer

coupling components.

• Proper lifting and assembling devices should be

on hand.

Installing the spacer coupling

Make sure the spacer coupling is clean.

Make sure the keys fit in key slots between

shafts and hubs properly with a small

clearance over the top to keep dynamic

balance.

TM082157

Spacer coupling

Pos. Description

1 Hub

2 Bolt

3 Lock nut

4 Sleeve

5 Disc pack

6 Spacer

7 Hub

1. Install the hub on the shaft. Make sure the shaft

end align with the hub end. If necessary, place

limit blocks to limit the gap between coupling and

shaft shoulder. Use shaft lock nut or end plate to

secure the hub axially. To achieve clearance fit,

install the hub on the shaft directly and use soft

hammer to hit the hub gently.

After the installation of hubs, apply rust

prevention to the hubs immediately.

9

English (GB)

Loading...

Loading...