English (GB)

6

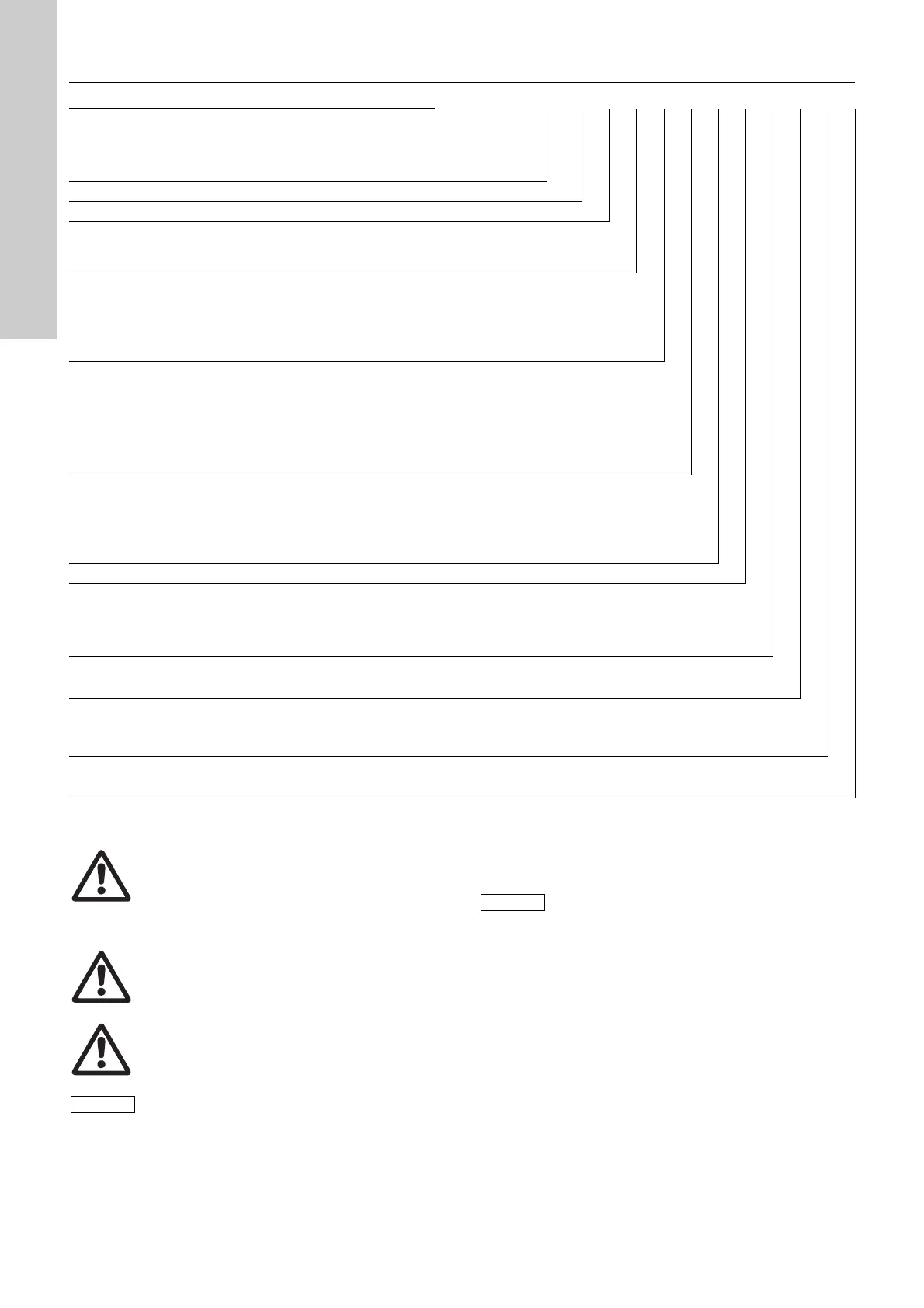

4.2 Type key

5. Mechanical installation

5.1 Handling

When lifting the motor, always use the eyebolts, if fitted.

Alternatively, lift the motor with both hands.

5.2 Mounting

The motor must be secured to a solid foundation by bolts through

the holes in the flange or the base plate.

5.3 Cable entries

The motor has four M20 screwed cable entries fitted with blind

plugs from factory. Various cable glands can be ordered from

Grundfos as accessory kits.

Code Example MG E 71 M A 2- 14 FT 85 -H A

[ ]

B

K

Type of motor unit

Complete motor with terminal box

Basic motor unit without terminal box

Kit for basic motor unit without terminal box

MG Motor Grundfos

E Electronic control

71

80

90

Frame size according to IEC (centre line height of motor shaft in mm, foot-mounted motor)

[ ]

S

M

L

Size of foot

Not defined for frame sizes 71 and 80

Small

Medium

Large

Length of

stator core

Rated motor power, P2 [kW]

1450-2000 min

-1

2900-4000 min

-1

4000-5900 min

-1

A

B

C

D

30 mm

45 mm

60 mm

85 mm

0.37

0.55

0.75

1.1

0.75

1.1

1.5

2.2

1.1

1.5

2.2

-

1

2

3

4

Maximum speed

5900 min

-1

4000 min

-1

3600 min

-1

2000 min

-1

Shaft end diameter [mm]

[ ]

FT

FF

Flange version

Foot-mounted (B3)

Tapped-hole flange

Free-hole flange

[ ]

Pitch circle diameter [mm], flange version

B3

H

I

Model designation

Single-phase

Three-phase

A

Version designation

First version

Warning

Installation and operation must comply with local

regulations and accepted codes of good practice.

Warning

Observe local regulations setting limits for

manual lifting or handling.

Warning

Before lifting the motor, pay attention to the

motor weight stated on the nameplate.

Do not lift the motor by the terminal box.

In order to maintain the UL mark, additional

installation procedures must be followed.

See page 35.

Loading...

Loading...