7

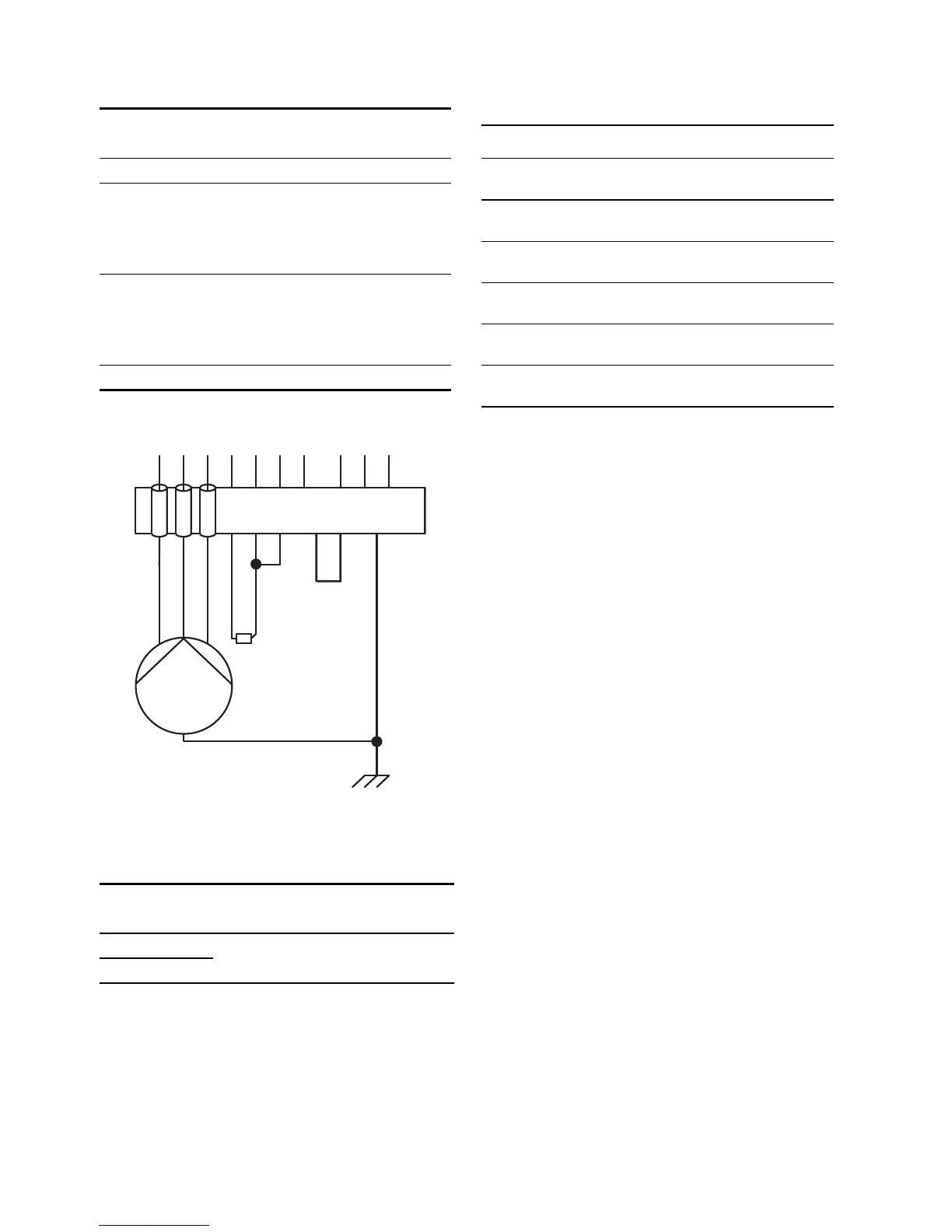

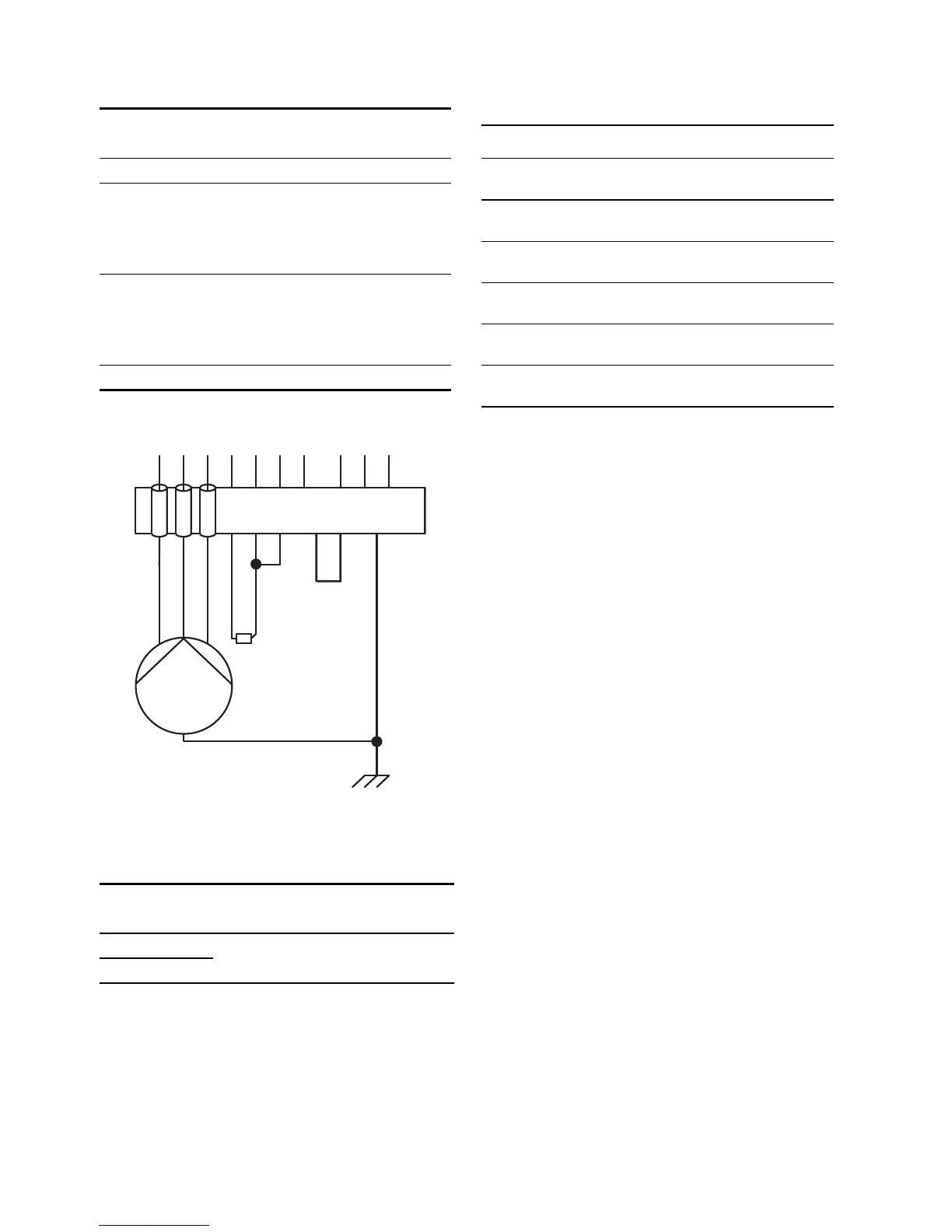

6.2 Input for Pt100/Pt1000

See fig. 6, pos. 5.

For examples of Pt100/Pt1000 connection,

see figs. 7 and 8.

Fig. 7 Two-core Pt100/Pt1000 connection

6.3 Input for PTC/thermal switch

See fig. 6, pos. 3.

If not used, short-circuit the PTC input using a wire,

or deactivate it with the R100. See section 9.4.11.

6.4 Back-up fuses

Maximum back-up fuse sizes which may be used for

the MP 204 appear from the table below:

At motor currents up to and including 120 A, the

cables to the motor can be taken direct through the

I1-I2-I3 of the MP 204.

At motor currents above 120 A, current transformers

must be used. See fig. 5, pos. 1.

Note: If back-up fuses above 50 A are used, the

L1-L2-L3 and "5" to the MP 204 must be protected

separately with max. 10 A fuses. See fig. 8.

If current transformers are used, the L1-L2-L3 and

"5" to the MP 204 must be protected with max. 10 A

fuses.

For installation examples, see figs. 8 to 12.

Terminal

designation

Description

+ Resistance input.

C

Correction for lead resistance.

To be connected by means of a

three-core Pt100/Pt1000 connec-

tion, otherwise the two "C" termi-

nals are to be short-circuited.

C

Correction for lead resistance.

To be connected by means of a

three-core Pt100/Pt1000 connec-

tion, otherwise the two "C" termi-

nals are to be short-circuited.

SH 0 V (screen).

TM03 1397 2205

Terminal

designation

Description

T1

Connection of PTC/thermal switch

T2

Loading...

Loading...