English (GB)

13

Proceed as follows:

1. Remove the fuses, and check that the impeller

can rotate freely. Turn the grinder head by hand.

2. Check the condition of the oil in the oil chamber.

See also section 8.4 Oil check and oil change.

3. Check whether the monitoring units, if used, are

operating satisfactorily.

4. Check the setting of the air bells, float switches

or electrodes.

5. Open the isolating valves, if fitted.

Auto coupling: It is important to grease the

gasket of the guide claw before lowering the

pump into the pit.

6. Lower the pump into the liquid and insert the

fuses.

Auto coupling: Check that the pump is in the

right position on the auto-coupling base unit.

7. Check that the system has been filled with liquid

and vented. The pump is self-venting.

8. Switch on the power supply to the pump. When

power is on, the pump will start and pump down

to the dry-running level. This process can be

used to check that the pump functions correctly.

After one week of operation or after replacement of

the shaft seal, check the condition of the oil in the

chamber. See section 8. Servicing and maintaining

the product.

4.5 Resetting the pump

To reset the pump, switch off the power supply to the

pump for one minute, and switch it on again.

5. Handling and storing the product

5.1 Handling the product

Before handling the product, see section 3.1.1 Lifting

the product.

5.2 Storing the product

During long periods of storage, protect the pump

against moisture and heat.

After a long period of storage, inspect the pump

before putting it into operation. Make sure that the

impeller can rotate freely. Pay special attention to the

condition of the shaft seal and the cable entry.

6. Product introduction

6.1 Product description

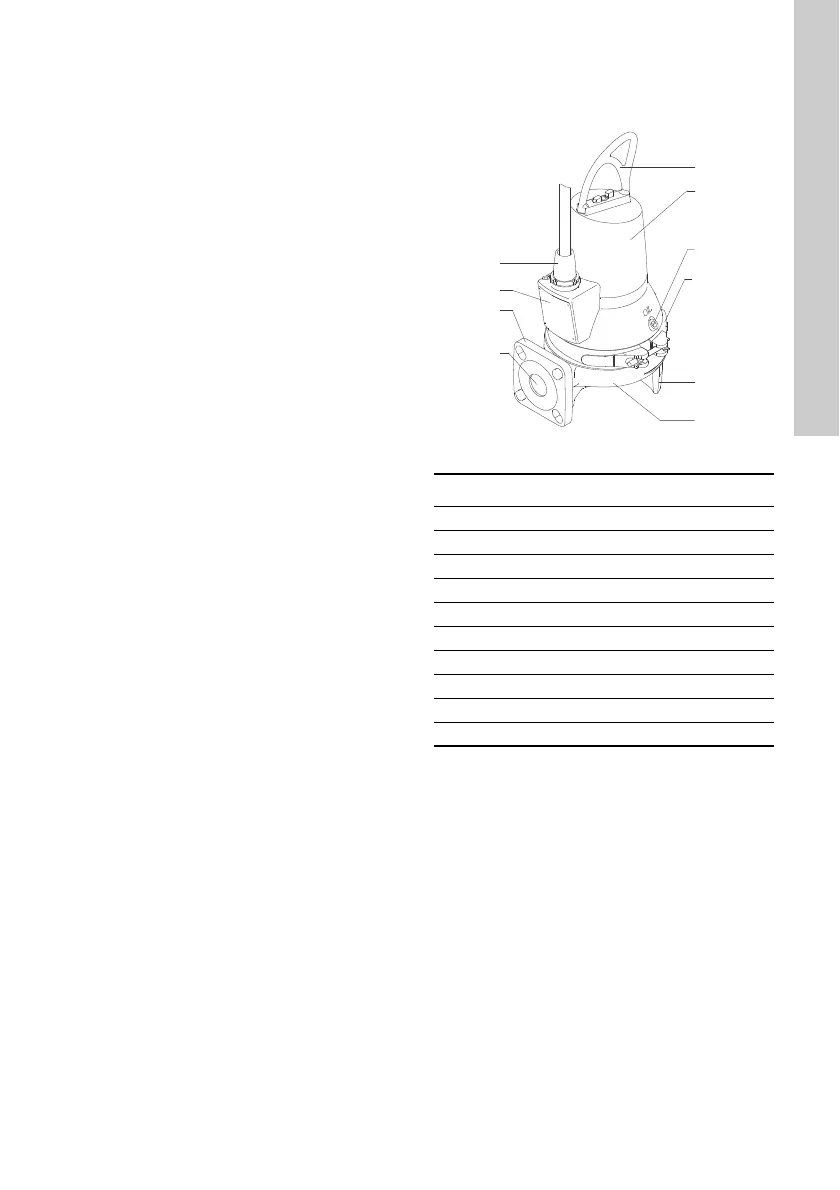

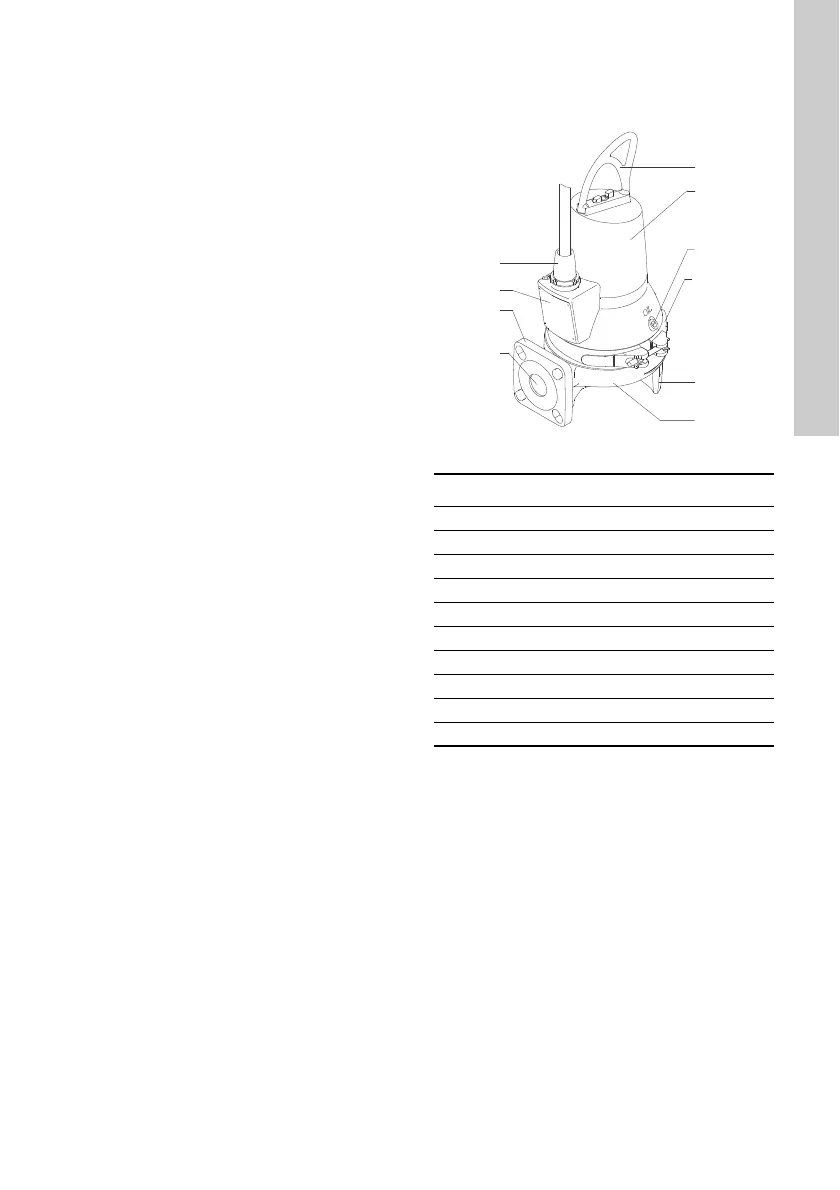

Fig. 9 SEG pump

TM06 5740 0116

Pos. Designation

1 Cable plug

2Nameplate

3 Outlet flange DN 40 and 50

4 Outlet port

5 Lifting bracket

6 Stator housing

7Oil screw

8 Clamp

9 Pump foot

10 Pump housing

Loading...

Loading...