English (GB)

22

8.6 Replacing the grinder system

For position numbers in brackets, see fig, D in

Appendix.

Proceed as follows:

Dismantling

1. Loosen the screw (188a) in one of the pump feet.

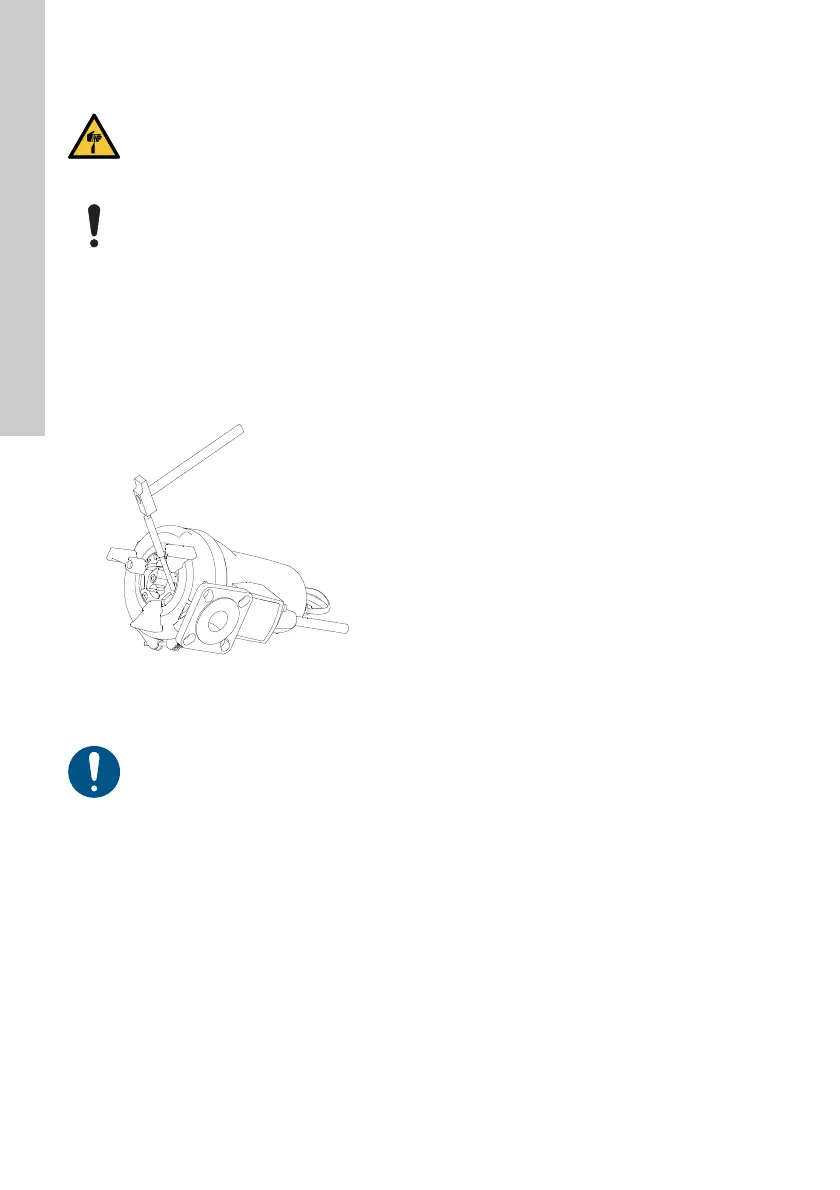

2. Loosen the grinder ring (44), and open the

bayonet socket by knocking or turning the grinder

ring 15 to 20 ° clockwise. See fig. 13.

Fig. 13 Removing the grinder ring

3. Gently prise the grinder ring (44) out of the pump

housing with a screwdriver.

4. Insert a punch into the hole in the pump housing

to hold the impeller.

5. Remove the screw (188a) in the shaft end and

the locking ring (66).

6. Remove the grinder head (45).

Assembly

1. When fitting the grinder head (45), the

projections on the back of the grinder head must

engage with the holes in the impeller (49).

2. Tighten the screw (188a) for the grinder head to

20 Nm. Do not forget the lock washer.

3. Fit the grinder ring (44).

4. Turn the grinder ring (44) 15 to 20 ° counter-

clockwise until it is tightened.

5. Check that the grinder ring does not touch the

grinder head.

6. Tighten the screw (188a) to 16 Nm.

8.7 Cleaning the pump housing

For position numbers in brackets, see fig. D in

Appendix.

Proceed as follows:

Dismantling

1. Stand the pump upright.

2. Loosen and remove the clamp (92) joining the

pump housing and the motor.

3. Lift the motor out of the pump housing (50). As

the impeller and grinder head are fastened to the

shaft end, the impeller and the grinder head will

be removed together with the motor.

4. Clean the pump housing and the impeller.

Assembly

1. Place the motor with the impeller and the grinder

head in the pump housing.

2. Fit and tighten the clamp (92).

See also section 8.8 Checking or replacing the shaft

seal.

CAUTION

Sharp element

Minor or moderate personal injury

- Beware of the sharp edges on the

impeller, grinder head and grinder ring.

During service the painted surface may be

damaged. Remember to restore the

painted surface by applying new paint.

TM06 5746 0116

Make sure that the grinder ring does not

get stuck against the grinder head.

Loading...

Loading...