GSI Group - Laser Division

JK300HP/JK300P/JK125P

Pre-installation and User Manual Issue 2.0

Page 160 of 172 Part No: 1EA300E01

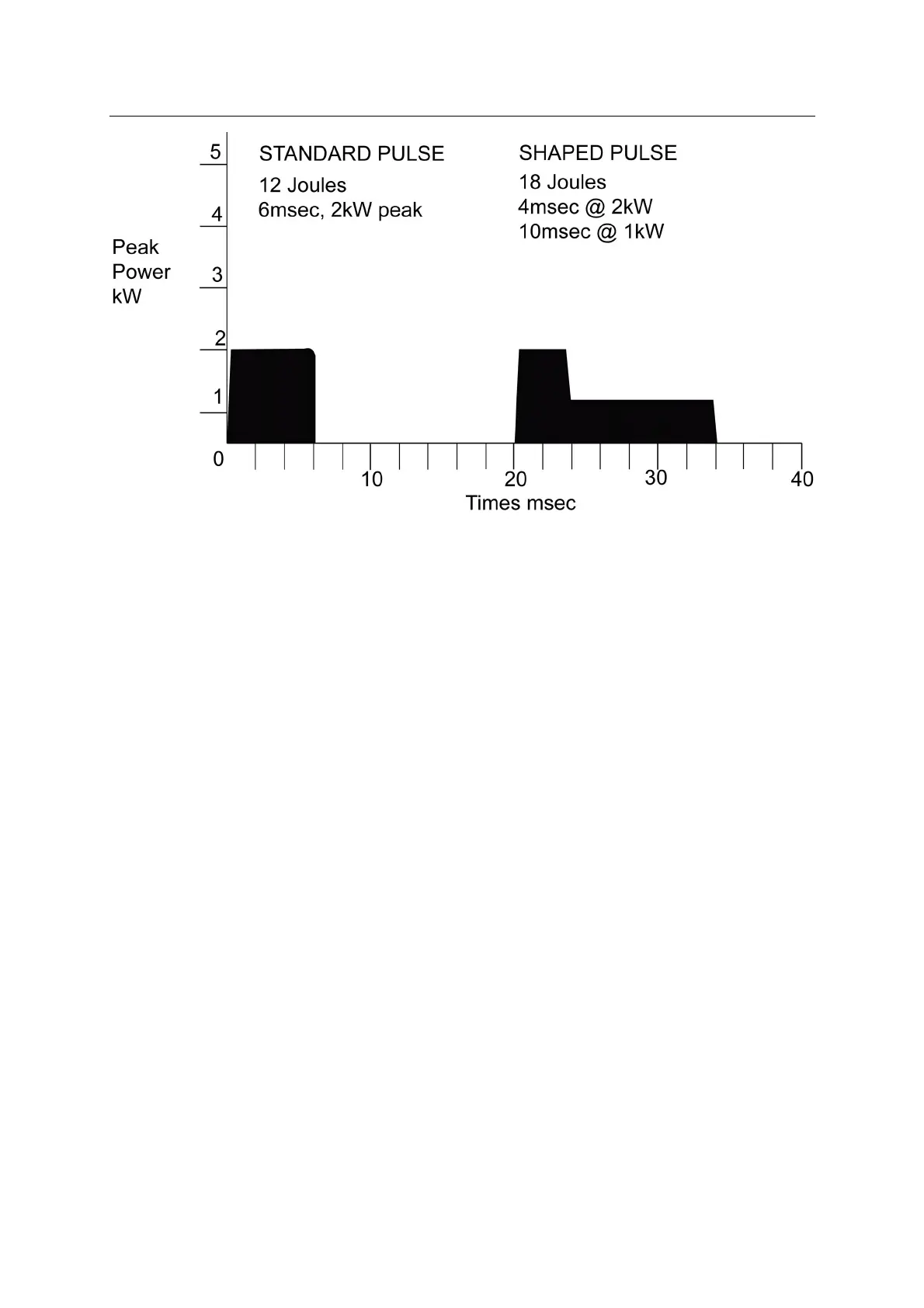

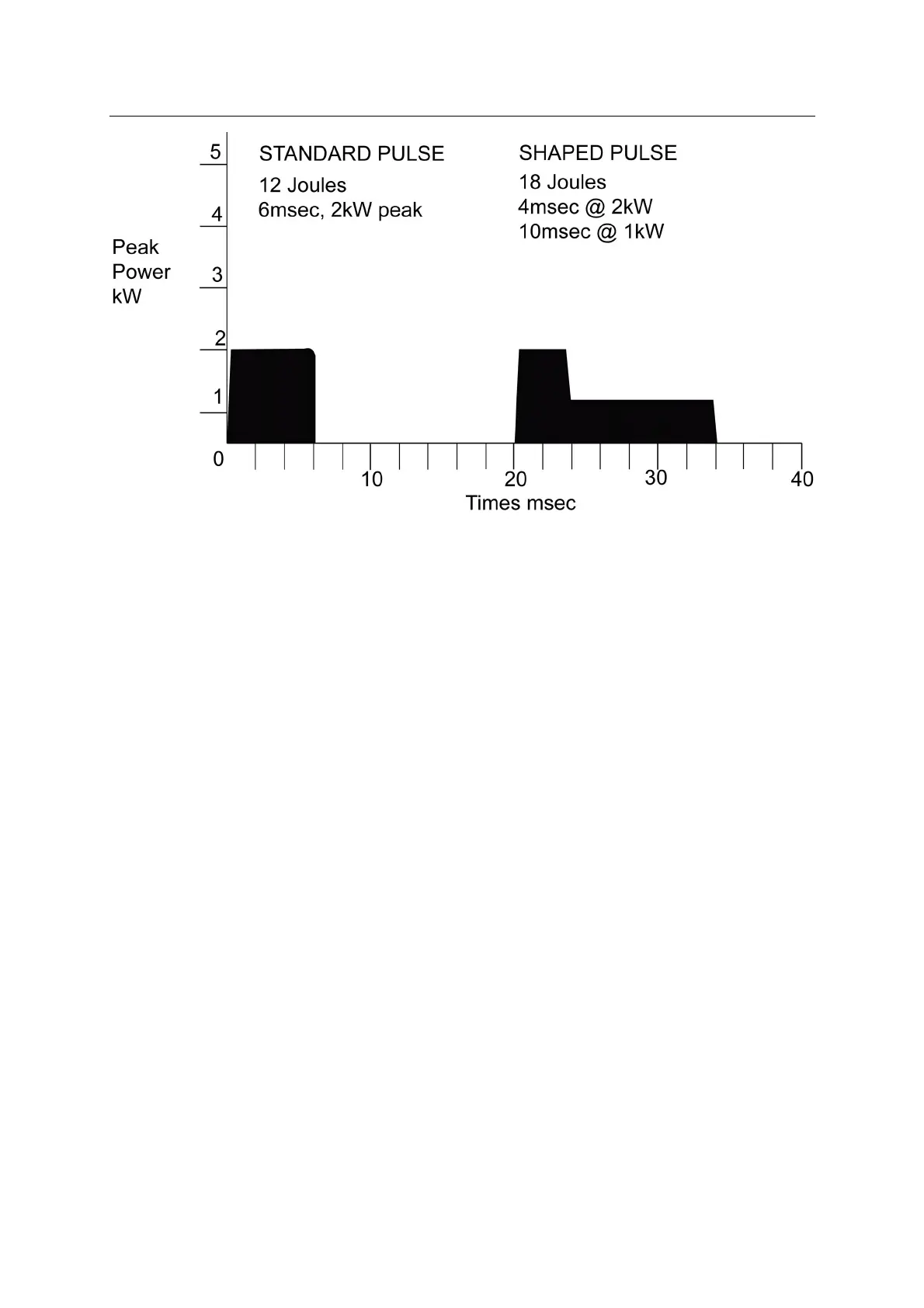

Figure 34 - Basic laser pulse and shaped pulse

The basic laser pulse from the pulsed laser is a rectangular pulse. Often the single sector

standard pulse is quite adequate when welding standard ferrous alloys without any coating

or carrying out standard pulsed YAG cutting applications. However, when welding reflective

or dissimilar materials, pulse shaping has a measurable effect on the quality and

consistency. Lasers are generally rated by their CW output, but pulsed lasers are discussed

in terms pulsed energy, peak power, pulse width and frequency.

10.2.1 Pulse energy

The volume of the melt puddle for each pulse is determined by pulse energy. There is a

minimum pulse energy required for weld penetration to a certain weld depth for a given

material. The energy per pulse, in Joules (E) is related to the average power (P) and the

pulse frequency (f) as follows:

E(Joules) = P (Watts) /f (Hz)

10.2.2 Peak Power

Refer to Figure 34, the height of the pulse is the peak power; peak power is required for

precious metal welding and a range of aluminium alloys. The peak power (P

p

) can be

calculated by the following:

P

p

(kW) = E (Joules) / t (seconds)

10.2.3 Pulse frequency and overlap

During pulsed ND: YAG welding, seam welds are produced by a series of spot welds. The

pulsing rate of the laser results in faster or slower seam welding as the rate is increased or

decreased. To produce hermetic welds, the pulse rate (f), spot diameter (d) and the weld

speed (v) have to be matched to produce the required percent overlap (%OL). In general,

typical values for hermetic welds are between 70 to 80 %OL and for non-hermetic welds are

between 50 to 60 %OL. The percent overlap can be calculated as follows:

%OL = 100[(d-v/f)/d]

Petitioners Canadian Solar Inc. and Canadian Solar (USA) Inc.

Ex. 1025, p. 160

Loading...

Loading...