IV) OPERATION

Temperature Adjustment

The National Plumbing code requires that the temperature

of residential electric service water heaters be set at 60°C

(140°F) (Canada), 49°C (120°F) (U.S.A.). The maximum

outlet temperature of some bath fixtures must be tempered

to 49°C (120°F) to reduce risk of scalding. Higher tempera-

tures increase the risk of scalding. The thermostats operate

automatically. They can be adjusted to provide warmer or

cooler water temperature. Set both thermostats to the

SAME setting (if applicable).

If water temperature adjustment is required:

1. Turn the electrical supply to the water heater "OFF".

2. Remove the access door(s) and insulation pad(s).

3. Check with a voltage tester at terminal 1 and 3 of the

limit control that power is indeed "OFF".

4. Adjust the thermostat(s) to the water temperature

desired (if a two-thermostat system exists, set both ther-

mostats at the same temperature).

5. Ensure insulation pad is in the door cavity. Replace

access door(s).

6. Turn the electrical supply to the water heater "ON".

Temperature Limit Control

For safety, a non-adjustable high limit temperature switch

will shut off the power when excessive water temperatures

are reached. This switch must be re-set manually. See

“Trouble-Shooting” section.

V) MAINTENANCE

Temperature & Pressure Relief Valve

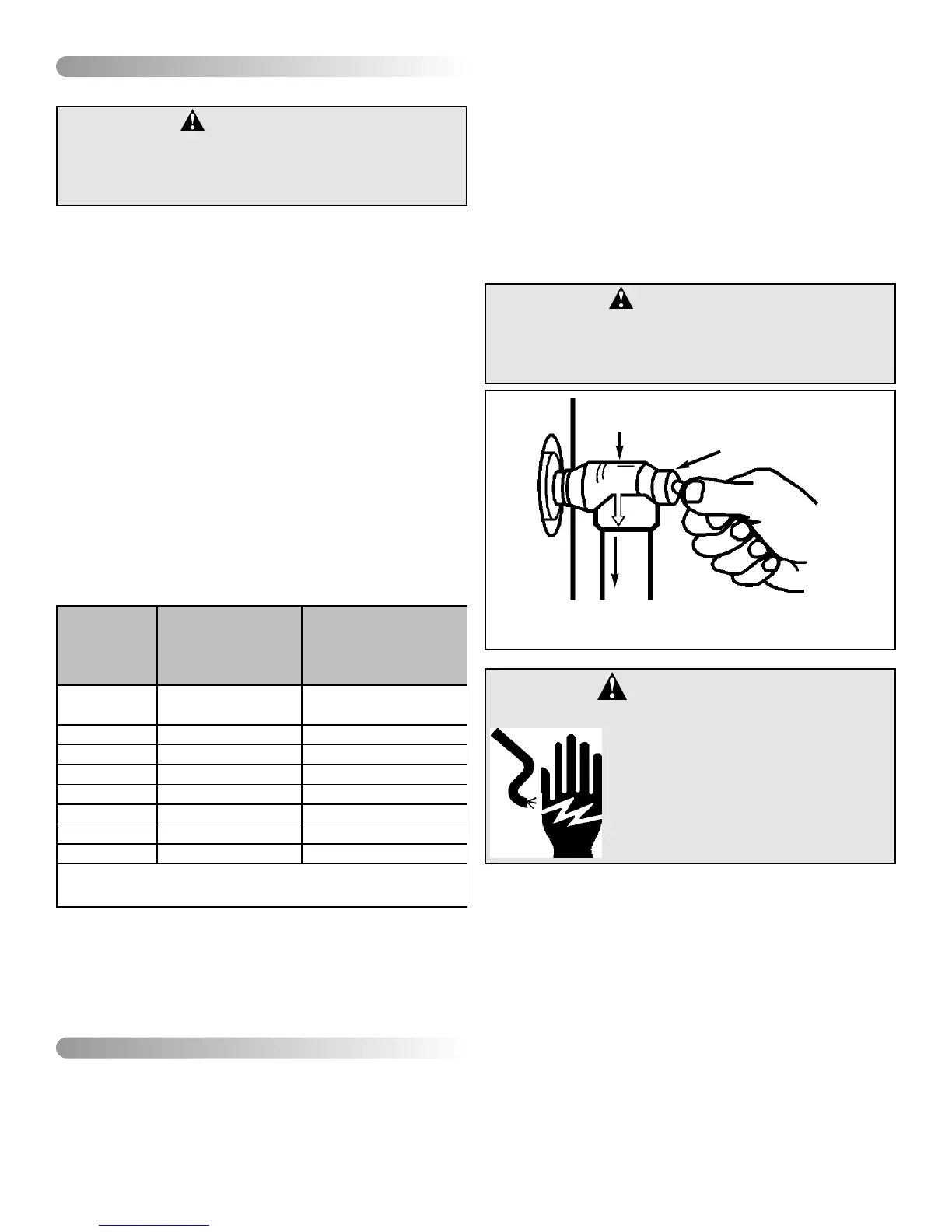

Manually operate the temperature and pressure relief valve

at least once a year to make sure it is working properly and

that there are no blockages. To prevent water damage, the

valve must be properly connected to a discharge line that

terminates at an adequate drain. Standing clear of the

outlet (discharged water may be hot), slowly lift and

release the lever handle on the temperature and pressure

relief valve (see Figure 3) to allow the valve to operate freely

and return to its closed position. If the valve fails to com-

pletely reset and continues to release water, immediately

turn "OFF" the electrical supply to the tank, and close the

cold water supply valve and call a qualified service techni-

cian. In systems where the relief valve discharges periodi-

cally, this may be due to thermal expansion causing pres-

sure build up. See “Pressure Build-Up (Thermal

Expansion)” section.

Element Replacement

1. See “Draining the Tank” section to remove water from

the heater.

2. Turn the electrical supply to the water heater "OFF".

3. Remove the access door(s) and insulation pad(s).

4. Disconnect wires from heating element terminals.

5. Unscrew the element using a 1-1/2 in. socket wrench or

tool number S1008, available from your water heater

distributor.

6. Replace element with new one, taking care that sealing

gasket is in the groove of element flange.

7. Re-connect wiring, and replace Di-Electric shields.

8. Ensure insulation pad is in the door cavity. Replace

access door(s).

9. Fill tank with water BEFORE turning ELECTRICITY on.

See “Filling the Tank” section.

– 7 –

WARNING:

Risk of scalding

There is a hot water scald potential if the

thermostat is set too high.

Loading...

Loading...