13

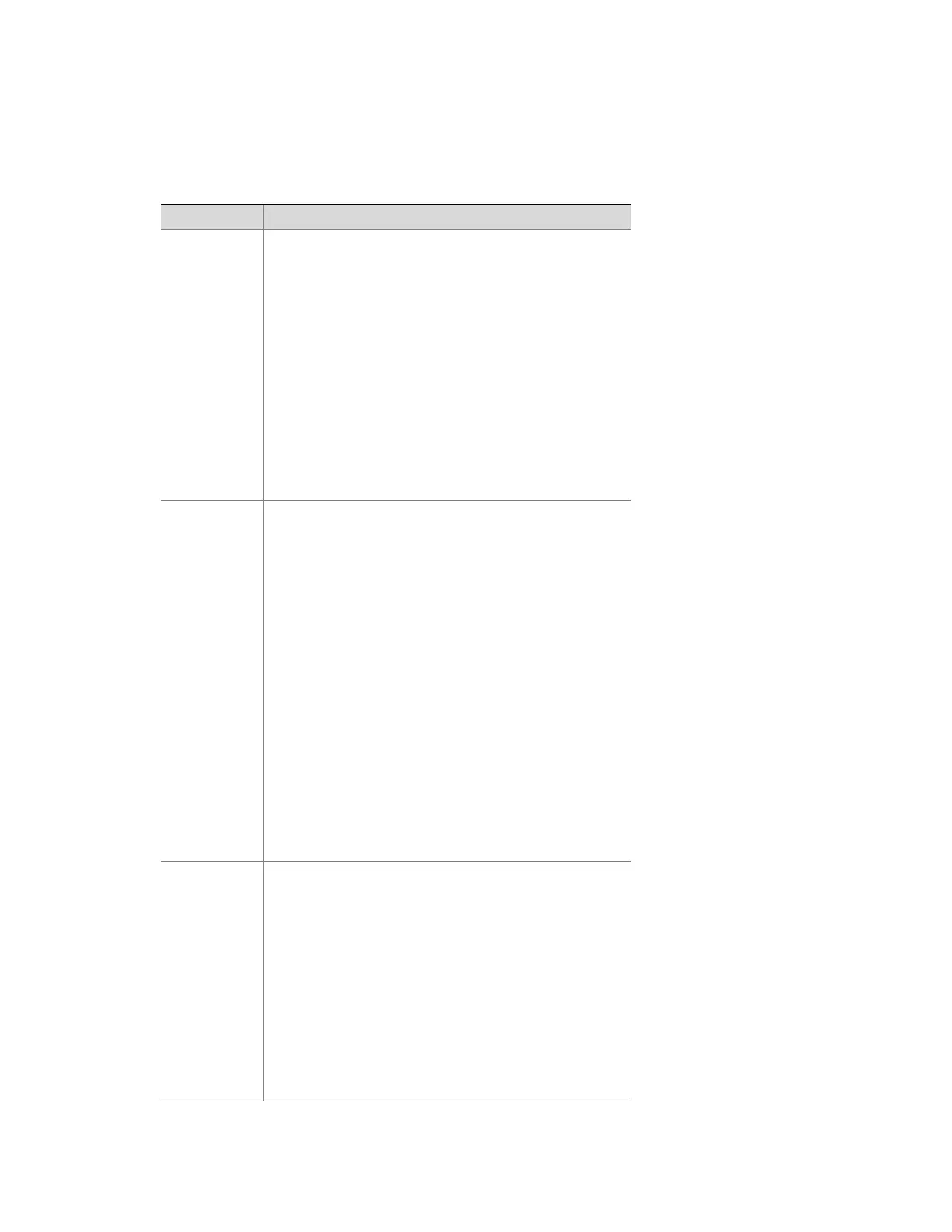

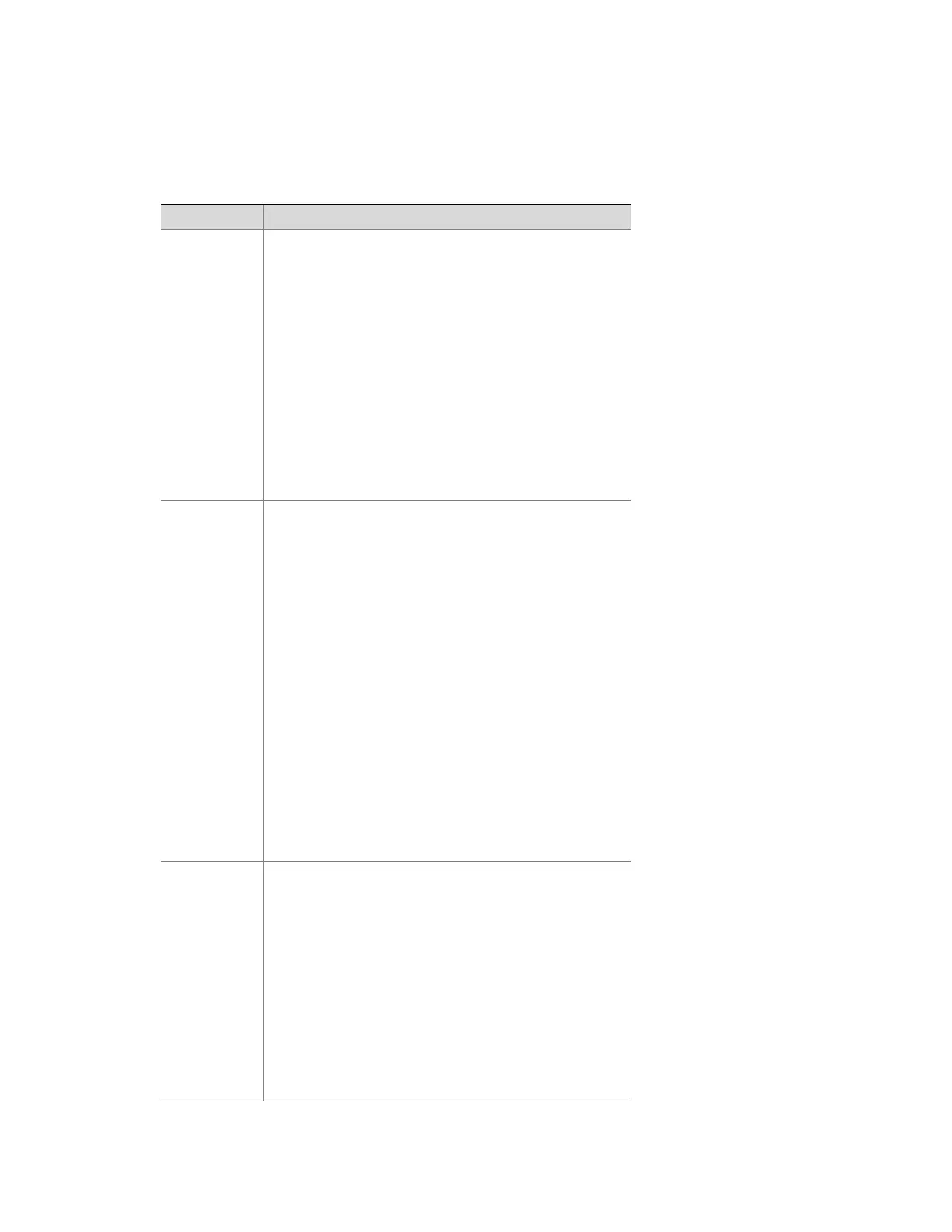

Grounding and lightning protection

Table 8 Grounding and lightning protection requirements

The grounding resistance is typically required to

be less than 5 ohms, and less than 10 ohms in an

area that has less than 20 thunderstorm days a

year. If an angle iron is to be buried into the

earth as the earthing conductor, the grounding

resistance is required to be less than 10 ohms. If

the installation site has a high earth resistance

rate, it is recommended to spray some salt water

or resistance-reducing agent on the earth

around the buried earthing conductor to

reduce the resistance rate of the earth.

The top of the earthing conductor should be at

least 0.7 m (2.30 ft) away from the ground

surface. In cold areas, the earthing conductor

should be buried below the frozen soil layer.

If a grounding strip is available at the site, attach

the yellow-green PGND cable of the AP to the

grounding strip. The PGND cable must have a

cross-section area of at least 6 mm

2

(0.01 in

2

)

and a length not longer than 3 m (9.84 ft).

If no grounding strip is available at the site,

hammer a 0.5 m (1.64 ft) or longer angle iron or

steel tube into the earth. The angle iron should

be sized at least 50 × 50 × 5 mm (1.97 × 1.97 ×

0.20 in.); the steel tube should have a wall

thickness of at least than 3.5 mm (0.18 in.) and

be zinc-plated. Weld the yellow-green

grounding cable to the angel iron or steel tube

and treat the joint for corrosion protection. With

a cross-section area of at least 6 mm

2

(0.01 in

2

),

the grounding cable should be as short as

possible. Do not coil the cable.

Make sure the lightning arresters of all devices

and the peering devices connected to these

devices are well grounded.

The grounding lead is a metal conductor

connecting the grounding strip to the

grounding grid. The PGND cable of the device

should be attached to the grounding strip. The

grounding lead should not be longer than 30

m (98.43 ft). H3C recommends a zinc-plated

flat steel with a cross-section area of 40 × 4 mm

(1.57 × 0.16 in) or 50 × 5 mm (1.97 × 0.20 in)..

The grounding strip and the grounding lead

should be jointed using a 35 mm2 yellow-green

PGND cable or directly welded together with

the joint treated for corrosion protection.

Loading...

Loading...