For worn ropes, when rope diameter

is < 10 mm or < 7.4 mm:

Replace the rope!

Oil level in inspection

glass

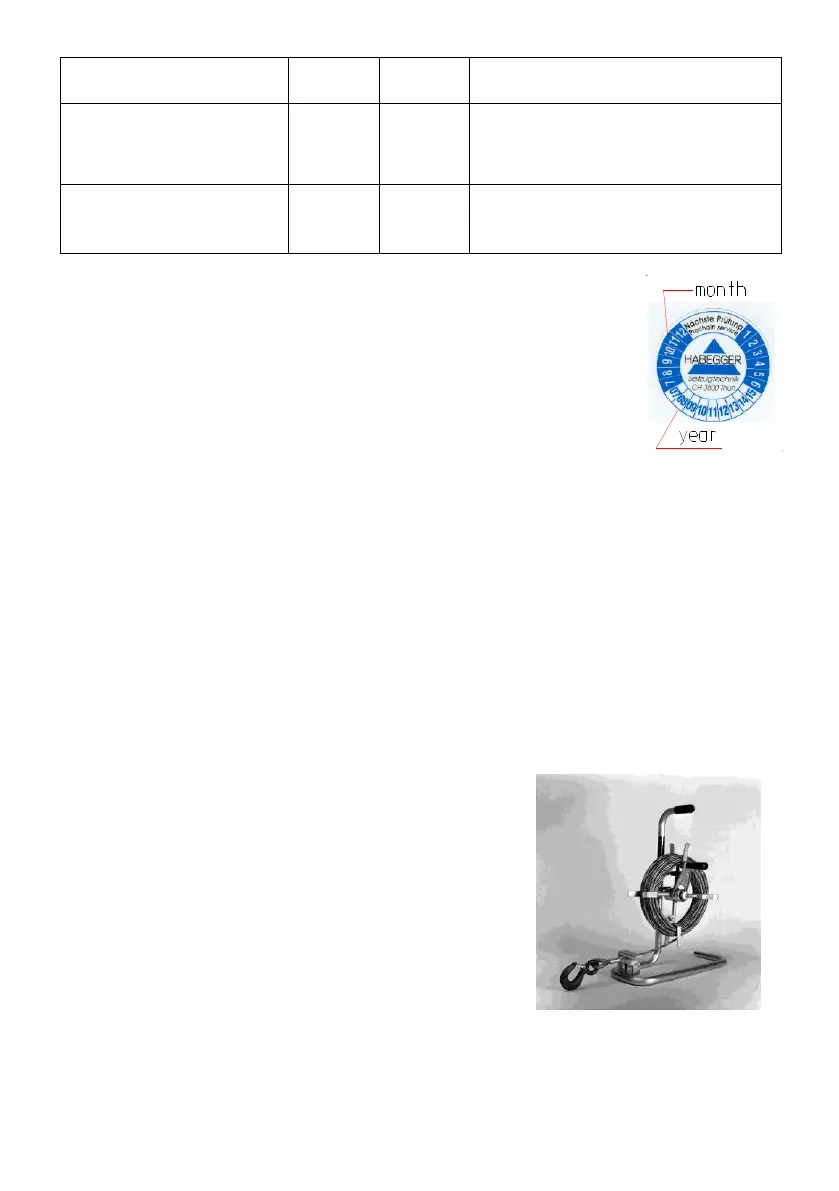

The machine, rope and accessories have to be checked at least

every 2 years (see label on the control box) by the manufacturer or an

authorized site. During this inspection, all parts are checked for

deformation, wear and tears.

Furthermore, an expert should also carry out inspections between the

annual inspections, depending on the operating and application

conditions.

8 List of spare parts

The spare parts list can be found on pages 74 - 77

9. Accessories

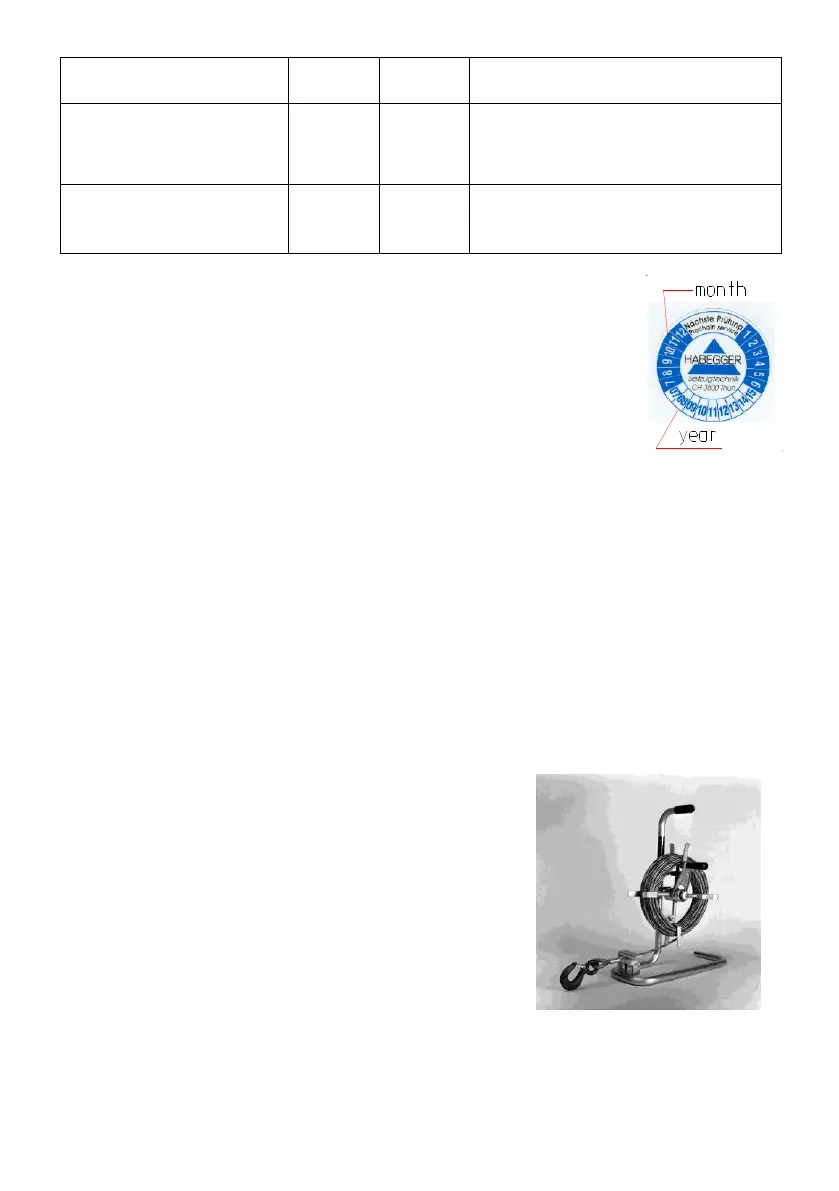

9.1 Reel drive

9.1.1 Rope coiler

The rope coiler is used to wind and unwind the rope on and off the reel easily.

1. Remove crank handle

2. Push reel onto the hub and clamp tightly into

place with the star grip.

3. Place rope below the rope guide.

4. Unwind the rope.

5. To wind up the rope, clamp the crank handle

onto the reel.

For ropes longer than 50 m we recommend to use the reel drive in

order to avoid malfunctions or accidents caused by the loose rope

which! Is lying around

Loading...

Loading...