105

Maintenance and Troubleshooting

15.3 TC sensor maintenance

15.3.1 Maintenance schedule

Service includes membrane replacement and external cleaning to restore the original sensor

sensitivity. This means low running costs and down time reduced to a minimum.

The membrane needs to be replaced once or twice a year depending on application conditions.

This can be tailored accordingly.

Note: If you are not familiar with ORBISPHERE sensor servicing, your Hach representative will be glad to

assist you

15.3.2 Testing the sensor condition

Periodically, inspect visually the sensor head for any deposits. Rinse it under clean tap water,

and dry with a clean tissue.

To verify the sensor, check measurements vs. a known standard sample value:

• If reading deviation is ±1% of the expected value, no action needs to be taken.

• If deviation exceeds ± 1%, perform a new calibration.

• If deviation exceeds 10% of the original values, replace the membrane.

15.3.3 Membrane replacement

To remove the membrane, follow the steps below:

1. Place the thermal conductivity sensor vertical with the head up. Remove the plastic storage

cap.

2. Unscrew the protection cap, using the tool provided in the maintenance kit.

3. Pay attention to the components inside the protection cap. Refer to TC sensor protection

caps and related part kits on page 113. Note the assembly order of each item.

Note: The illustration is an example only. Your configuration may differ.

4. Pull up the membrane holding ring with the tool provided in the maintenance kit. Remove

membrane(s).

Note: For correct membrane selection. Refer to TC sensor on page 14.

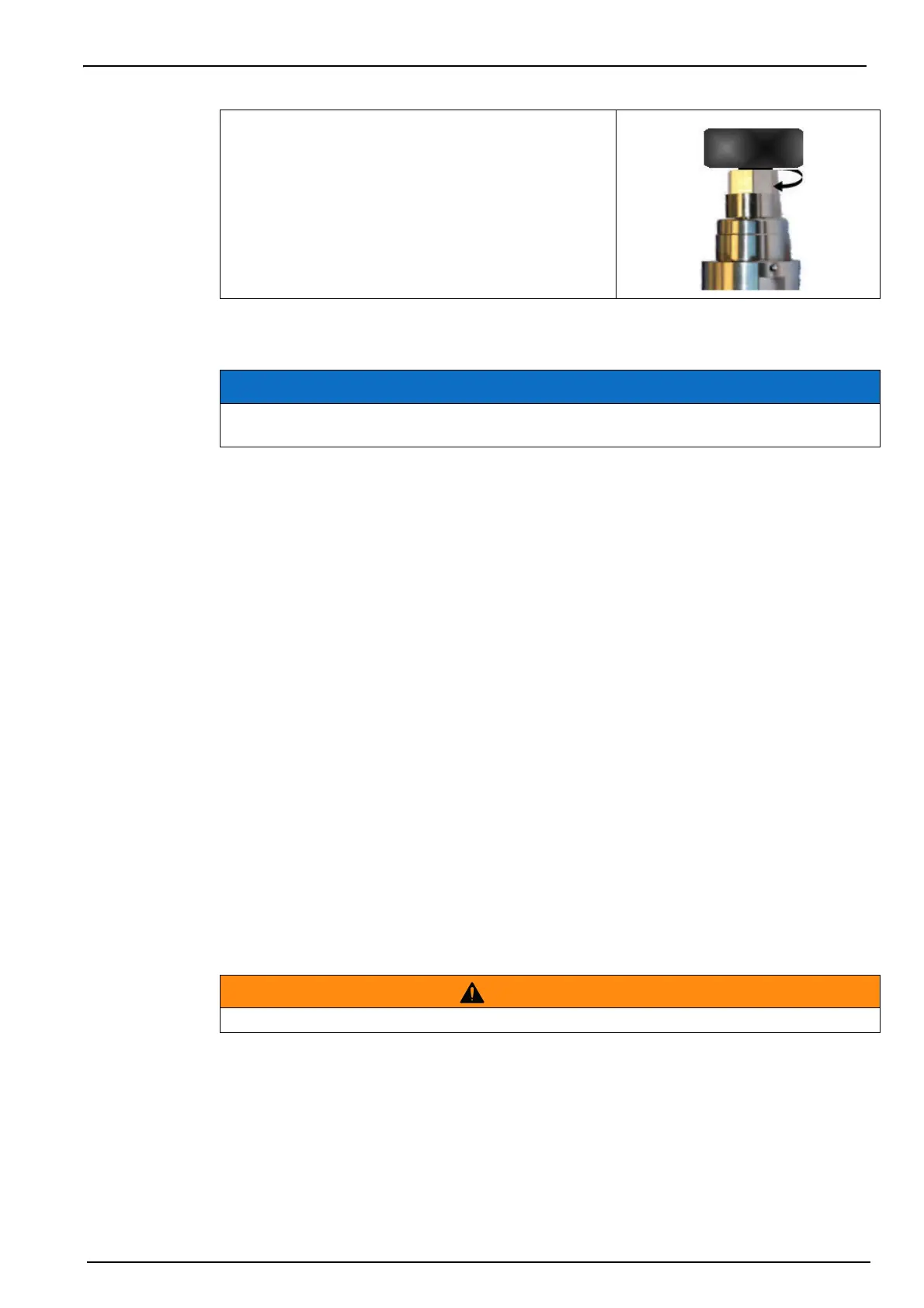

4. Turn the tool clockwise to screw in the new sensor

spot, finger tight. Do not overtighten. Once secure,

pull off the maintenance tool.

NOTICE

Carry out the maintenance in a clean dry place in order to avoid damaging the sensor's

precision components, and also to prevent water or humidity from getting into the sensor.

CAUTION

Never remove the protection cap, unless you plan to replace the membrane.

Loading...

Loading...