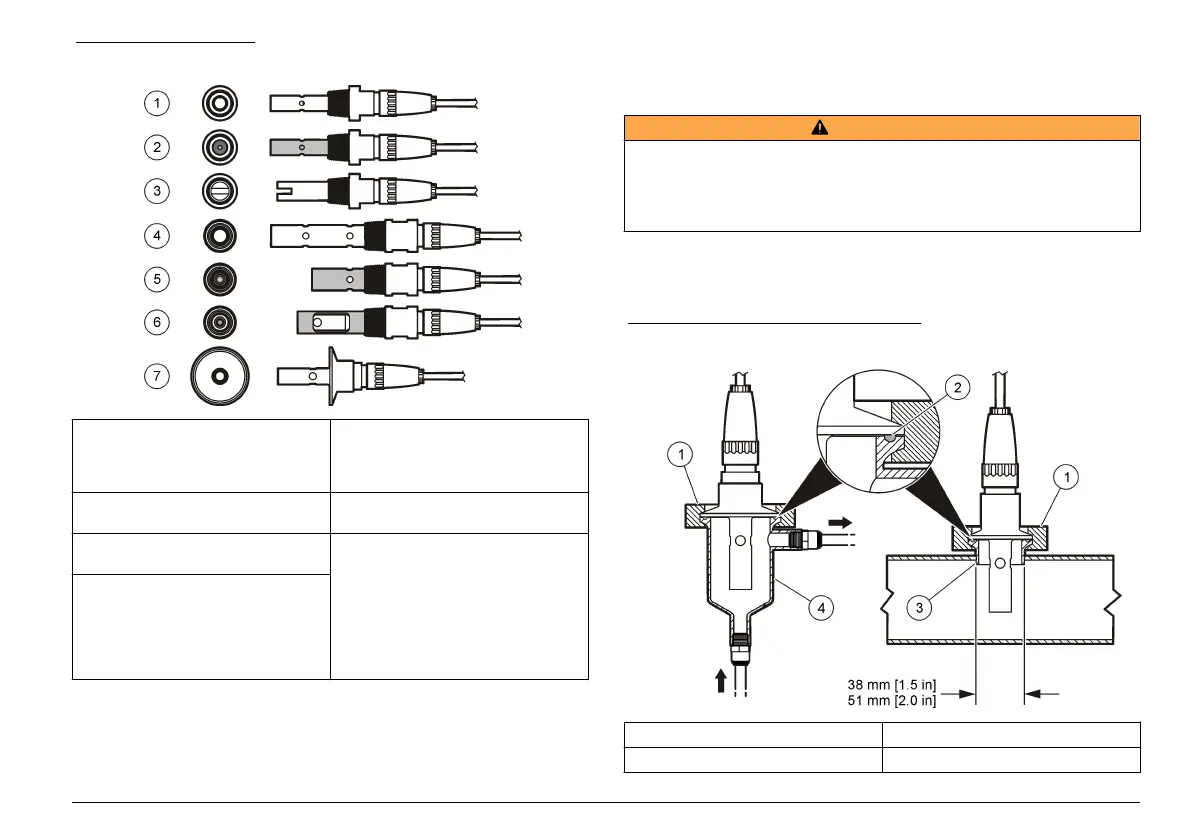

Figure 1 Sensor styles

1 8310, k = 0.01; applications include

drinking water, wastewater

treatement, chemical processes,

demineralized and softened water

5 8316, k = 0.1; same applications as

8315

2 8311, k = 0.1; same applications as

8310

6 8317, k = 1; same applications as

8315

3 8312, k = 1; same applications as

8310

7 8394, k = 0.01; sanitary style; 1.5-

or 2-in. diameter; applications

include ultrapure water monitoring

in pharmaceutical and food

industries and suitable for CIP-SIP

processes

4 8315, k = 0.01; applications include

pure water production monitoring

(ion exchangers and distillators)

and process water monitoring

(condensates, cleaning cycles and

heat exchangers)

Installation

Mounting

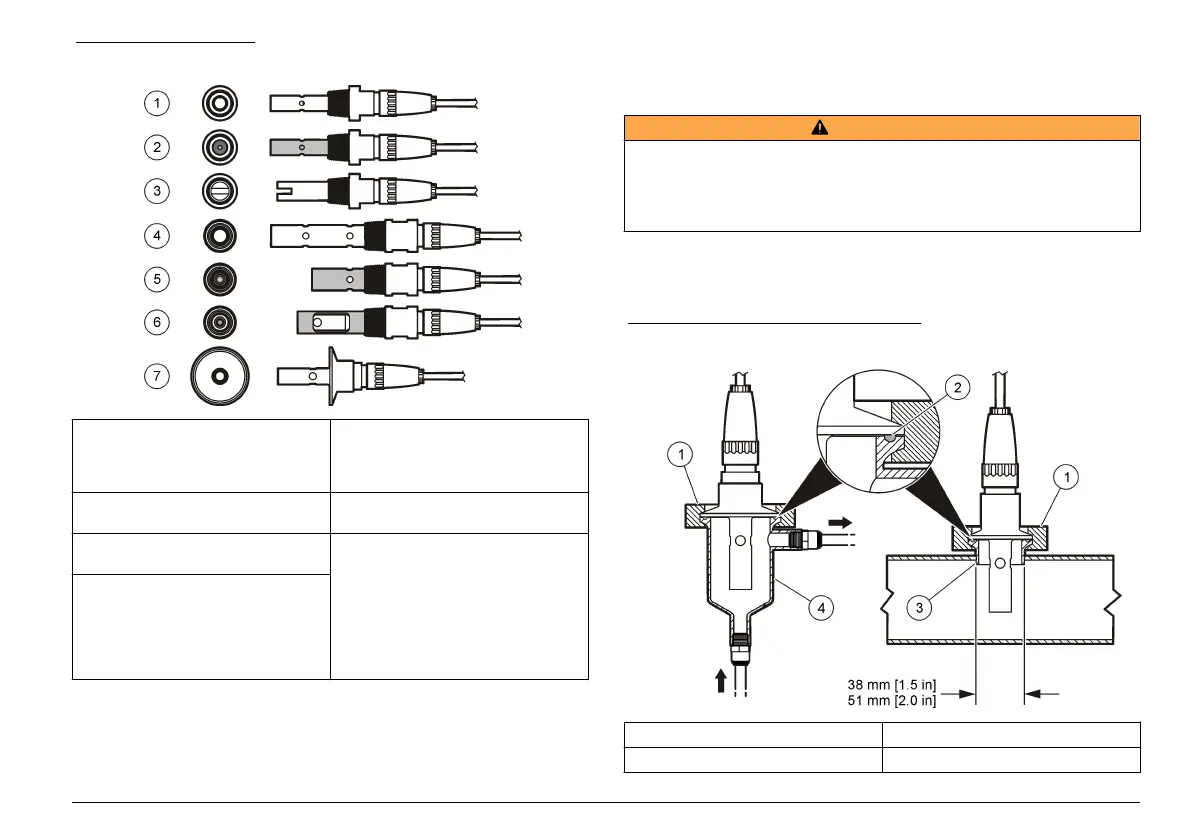

W A R N I N G

Personal injury hazard. Removal of a sensor from a pressurized vessel can be

dangerous. Installation and removal of these sensors should be done by

individuals trained in proper high pressure and temperature installation. Always

use industry approved hardware and safety procedures when dealing with high

pressure and/or temperature fluid transport systems.

For examples of sensors in different applications, refer to Figure 2 or

Figure 3. The sensor must be calibrated before use. Refer to Calibrate

the sensor on page 11.

Figure 2 Sanitary mounting examples

1 Sanitary clamp 3 Ferrule (welded to pipe)

2 Gasket 4 Flow-thru chamber

English 5

Loading...

Loading...