32

Installation and Maintenance Manual, Compact CA

3.1.11 Mounting MDA 5, 7 & 10

3.1.11 Reduction of brake torque

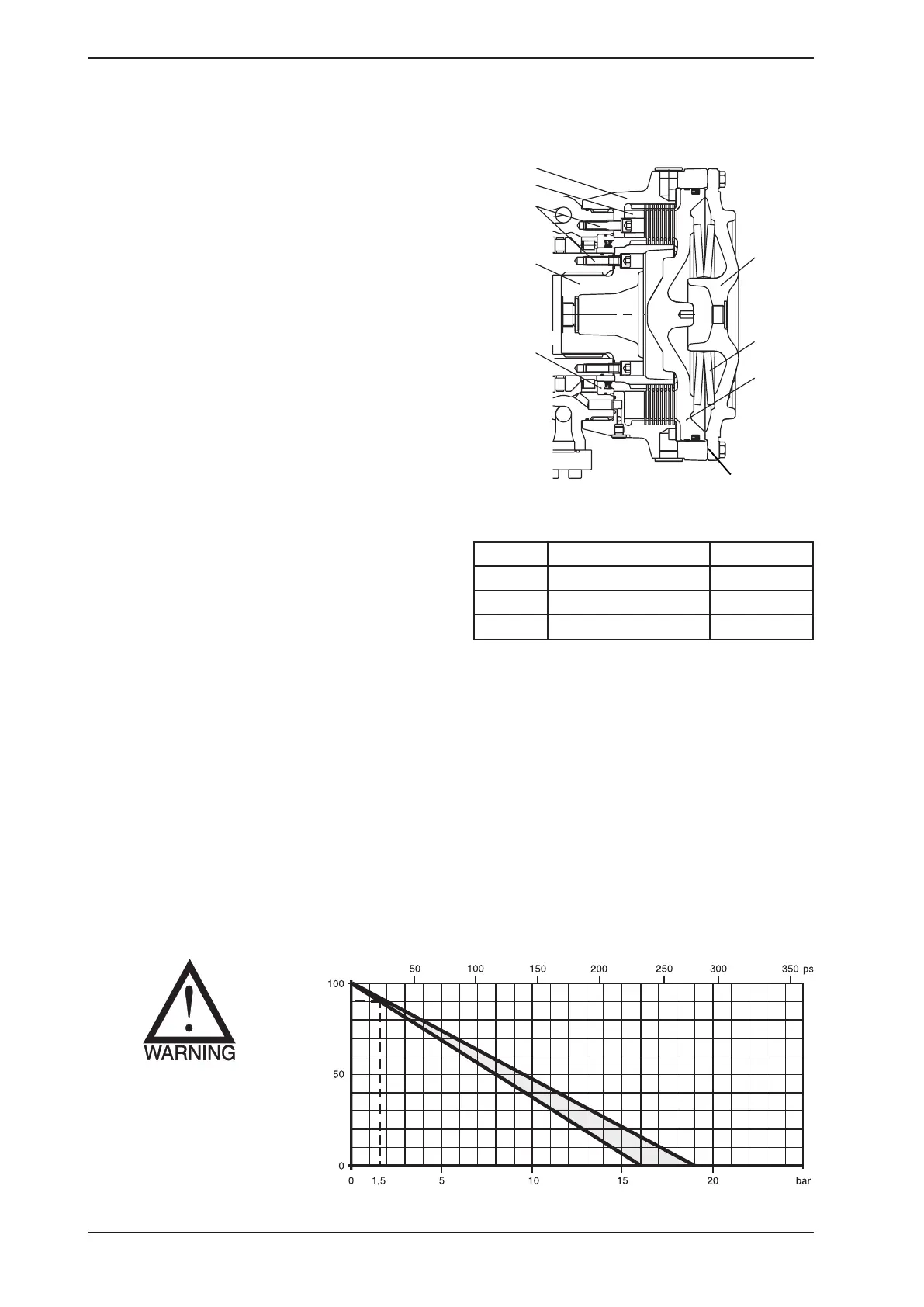

Figure 3.27

The brake is normally mounted on the motor

at the factory. If the brake is disassembled and

shall be mounted on a motor, it must be done

according to following.

1. Control that seal and Seal retainer (25) is

mounted according to figure 3.27.

2. Mount Disc centre (302) on the cylinder

block. Oil the screws (43) and assemble with

torque 136 Nm (100 lbf·ft).

3. Put the Brake housing (305) on the motor,

and mount the right spacer (3xx). Oil the

screws and mount them with tightening

torque 136 Nm (100 lbf·ft). See table 3.12.

4. Mount first one outer disc. Then mount inner

disc, outer disc until all discs are mounted.

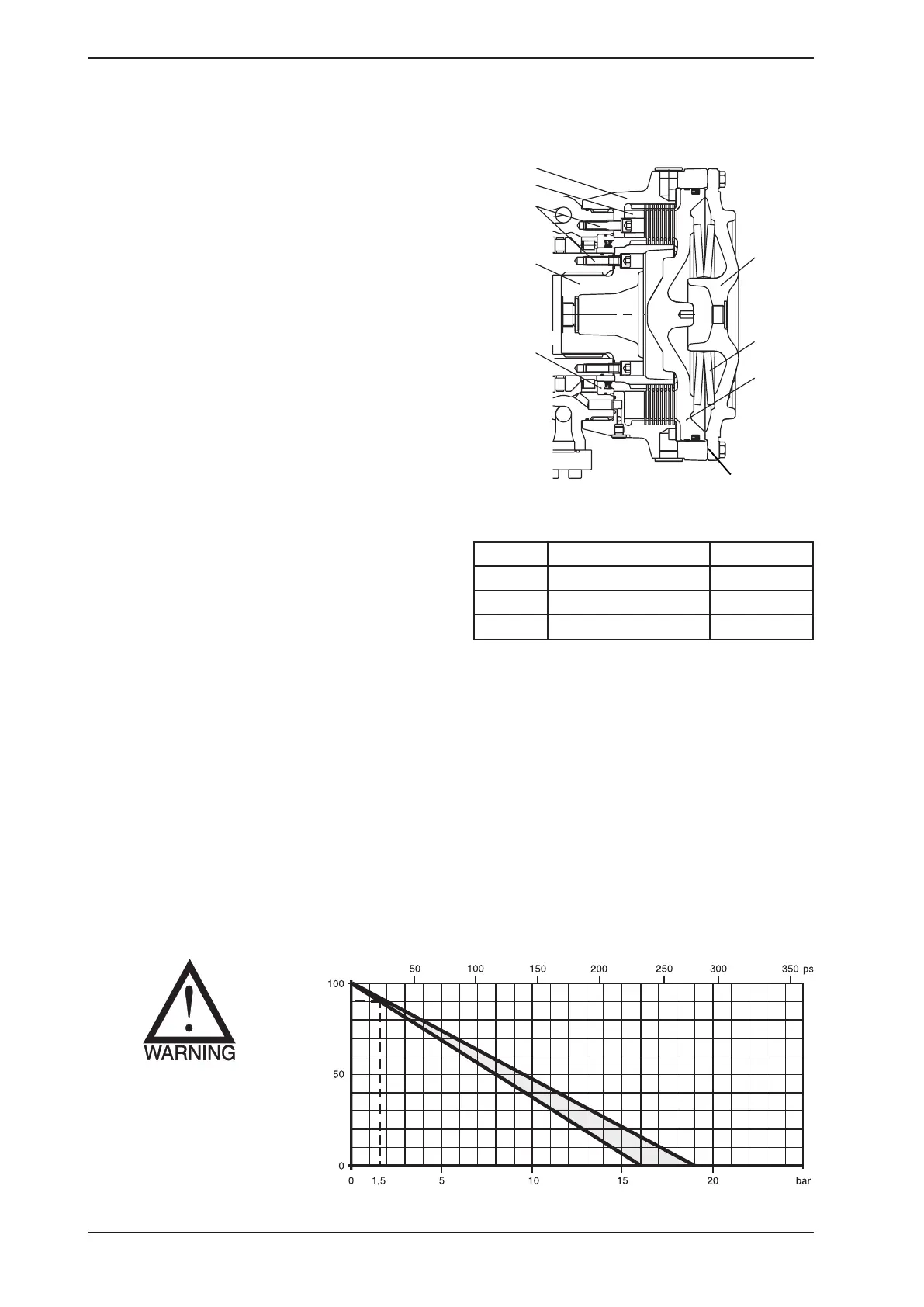

The diagram 3.1 below shows the falling brak-

ing torque M

max

for increasing pressure in the

brake cylinder drain.

Example: MDA 10 has a dynamic braking

torque of 41500 ± 2000 Nm (30600 ± 1480

lbf·ft), when the brake is not under pressure.

Assume that the pressure in brake cylinder

drain is 1.5 bar / 21.75 psi. The diagram shows

that the actual brake torque (M

act

) corresponds

to only 90% of M

max

.

Motors with SPECIAL

brakes may have differ-

ent working operation.

Please make sure that

you check the Ordering

code on your brake.

Diagram 3.1

Installation

Back pressure in brake cylinder drainage line.

MDA5 has 6 outer discs and 5 inner discs.

MDA7 has 8 outer discs and 7 inner discs.

MDA10 has 11 outer discs and 10 inner discs.

% Braking torque

Brake Screws (ISO 89811) Spacer

MDA 5 MC6S 12x50 12.9 t=54 (2.13)

MDA 7 MC6S 12x50 12.9 t=42.4 (1.67)

MDA 10 MC6S 12x50 12.9 t=25 (0.98)

Grease with

Hylomar

Table 3.12

5. Grease the seals with Texaco multifak or an

equivalent grease without solid additives and

mount the piston (313).

6. Grease the springs (315) with MoS

2

Mo-

lykote or an equivalent grease. Put the

springs on the Brake cover (314). The

springs shall be mounted against each other

on the inner diameter.

7. Grease Brake cover, contact surface be-

tween Brake cover and Brake housing with

a thin layer of Hylomar. Mount Brake cover

(314) on the brake. Oil the screws and as-

semble the screws. Start mounting by slightly

tightening the screws, no more than 1 turn

each. Continue with one turn of each screw

around the cover. Tightening torque is 114

Nm (84 lbf·ft).

Loading...

Loading...