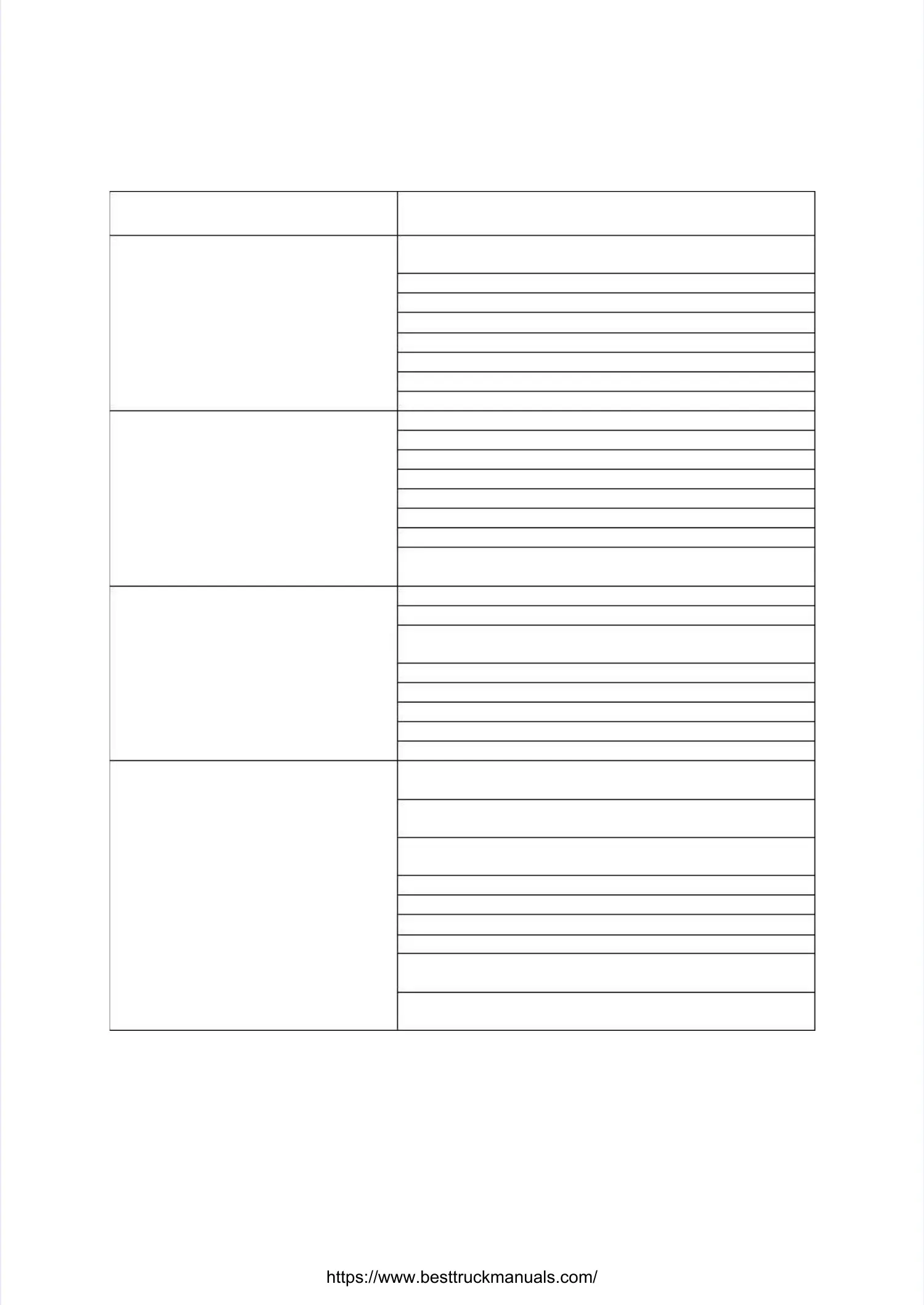

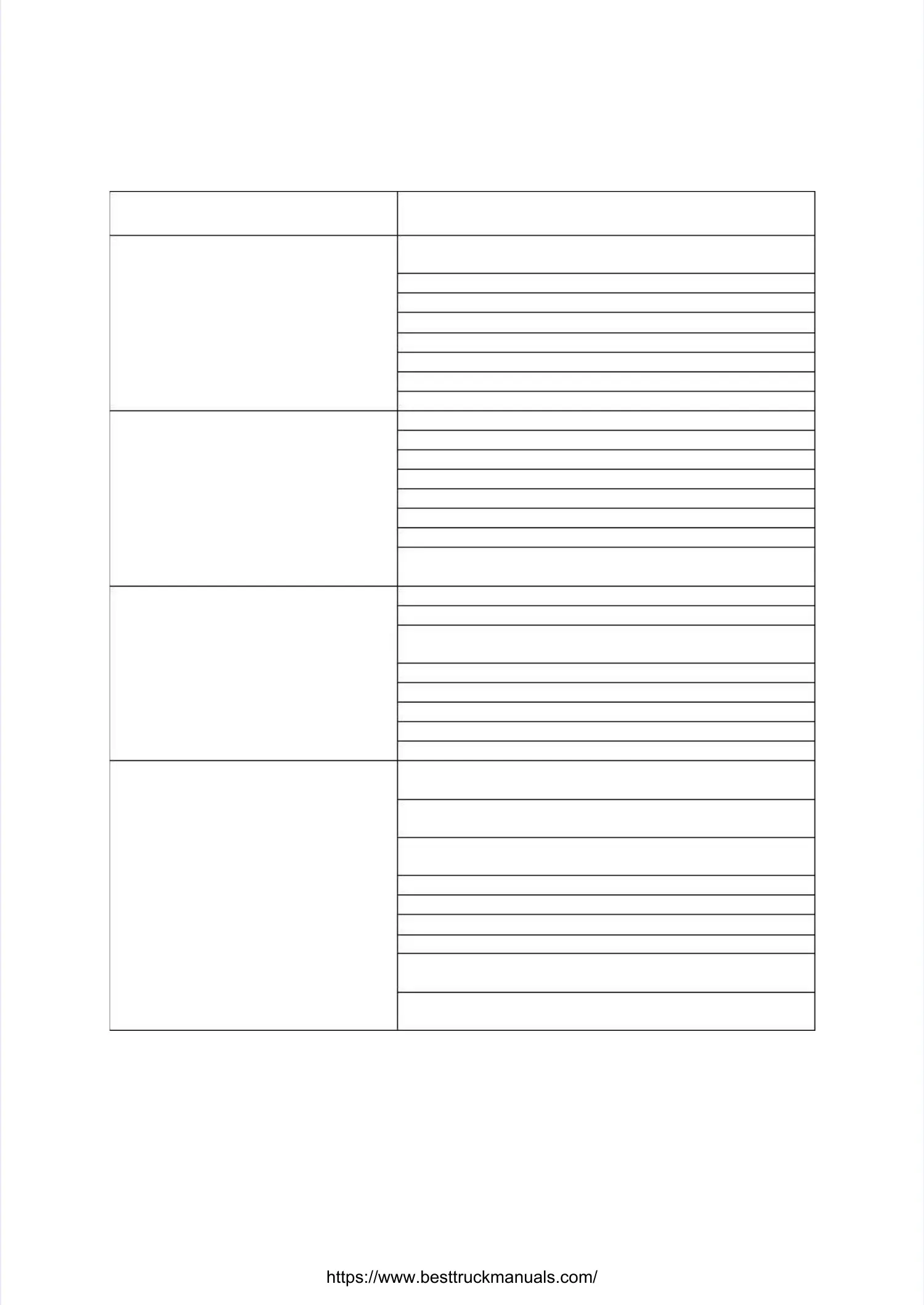

5656

Fault Fault Probable Probable causecause

AbnormaAbnormal noise when ml noise when motor runsotor runs

①①Insulation paper of rotor and stator or slot wedgeInsulation paper of rotor and stator or slot wedge

rubs.rubs.

②②There is foreign body as sand in oil or bearing wear.There is foreign body as sand in oil or bearing wear.

③③Stator and rotor core loosen.Stator and rotor core loosen.

④④Bearing lack oil.Bearing lack oil.

⑤⑤

Air duct stufAir duct stuffing or fan rubs fing or fan rubs the fan housinthe fan housing.g.

⑥⑥Stator and rotor core rub.Stator and rotor core rub.

⑦⑦

Power voltage too high or imbalance.Power voltage too high or imbalance.

⑧⑧Wrongly stator winding or short circuit.Wrongly stator winding or short circuit.

Big motor vibration during runningBig motor vibration during running

①①

Too big wear bearing clearanceToo big wear bearing clearance

②②Uneven air gapUneven air gap

③③

Rotor imbalanceRotor imbalance

④④Revolving shaft bend.Revolving shaft bend.

⑤⑤

Iron core deforms or loosens.Iron core deforms or loosens.

⑥⑥Housing or basic capacity is insufficient.Housing or basic capacity is insufficient.

⑦⑦

Motor foot screw loosenMotor foot screw loosen

⑧⑧Open circuit of cage rotor open welding, open circuitOpen circuit of cage rotor open welding, open circuit

of wound rotor, or winding fault with stator.of wound rotor, or winding fault with stator.

Bearing overheat.Bearing overheat.

①①

Over much or few greaseOver much or few grease

②②

Bad oil quantity and contains impurity.Bad oil quantity and contains impurity.

③③Mismatch between bearing and journal or endMismatch between bearing and journal or end

cap(too loose or too tight)cap(too loose or too tight)

④④

Eccentricity of bearing bore, rub with the axle.Eccentricity of bearing bore, rub with the axle.

⑤⑤Motor end cap or bearing cap not even assembledMotor end cap or bearing cap not even assembled

⑥⑥

Coupling between motor and load not adjustCoupling between motor and load not adjust

⑦⑦Too large or too small bearing clearanceToo large or too small bearing clearance

⑧⑧

Motor axle bend.Motor axle bend.

Motor overheating or smokingMotor overheating or smoking

①①Too high power voltage, greatly increase the coreToo high power voltage, greatly increase the core

heating.heating.

②②

Too low power voltage, the motor drives rated load,Too low power voltage, the motor drives rated load,

over large current heats the winding.over large current heats the winding.

③③When remove winding for overhaul, use improperWhen remove winding for overhaul, use improper

way that burn the iron core.way that burn the iron core.

④④Rotor and stator core rub.Rotor and stator core rub.

⑤⑤

Motor overloads or start up frequently.Motor overloads or start up frequently.

⑥⑥Cage rotor break.Cage rotor break.

⑦⑦

Motor lacks phase, two phases run.Motor lacks phase, two phases run.

⑧⑧After After rewinding, rewinding, dipping dipping paint paint of of stator stator winding winding isis

improper.improper.

⑨⑨

In high temperature, much dirt on the motor surfaceIn high temperature, much dirt on the motor surface

or ventilation duct block.or ventilation duct block.

Loading...

Loading...