5858

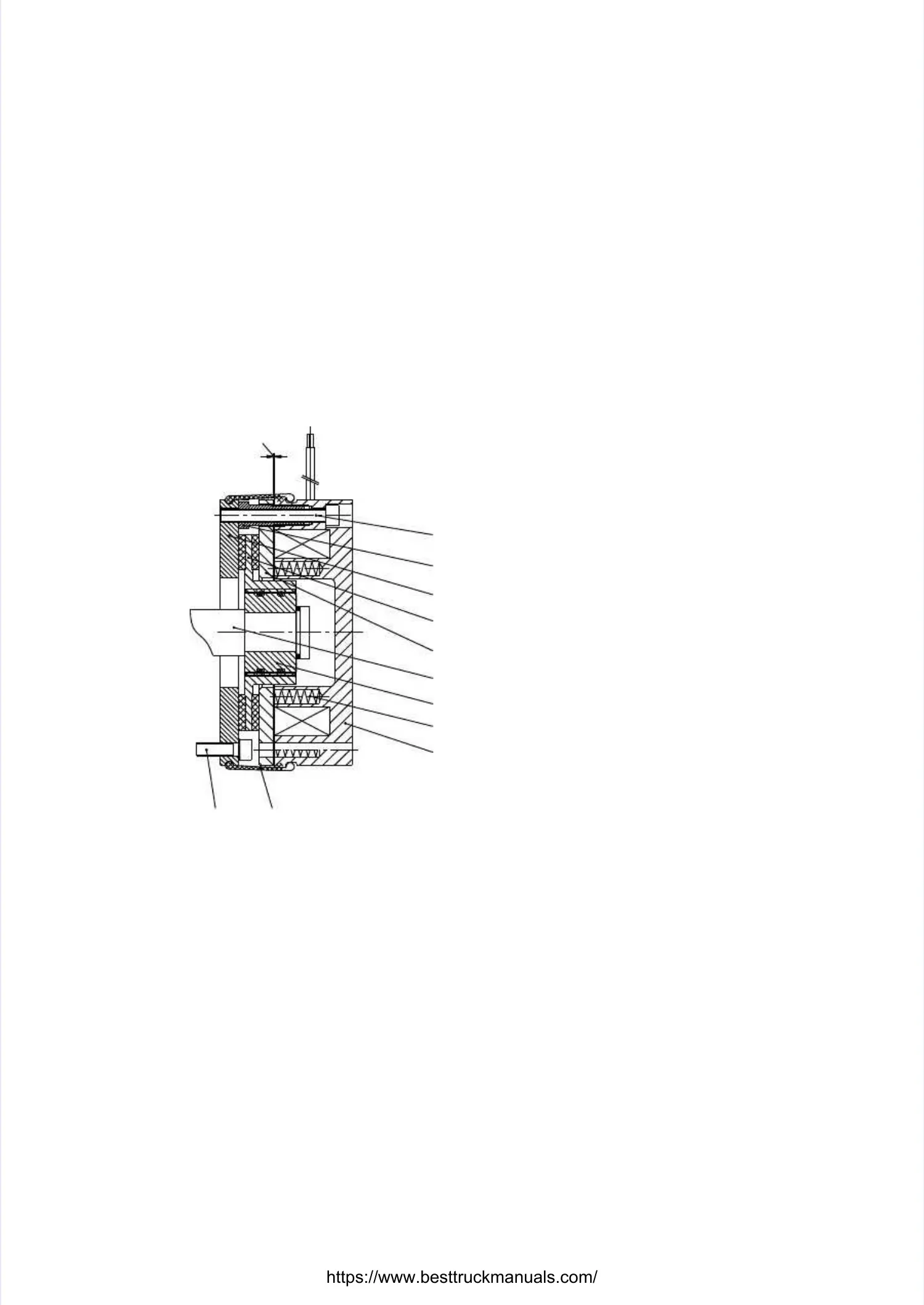

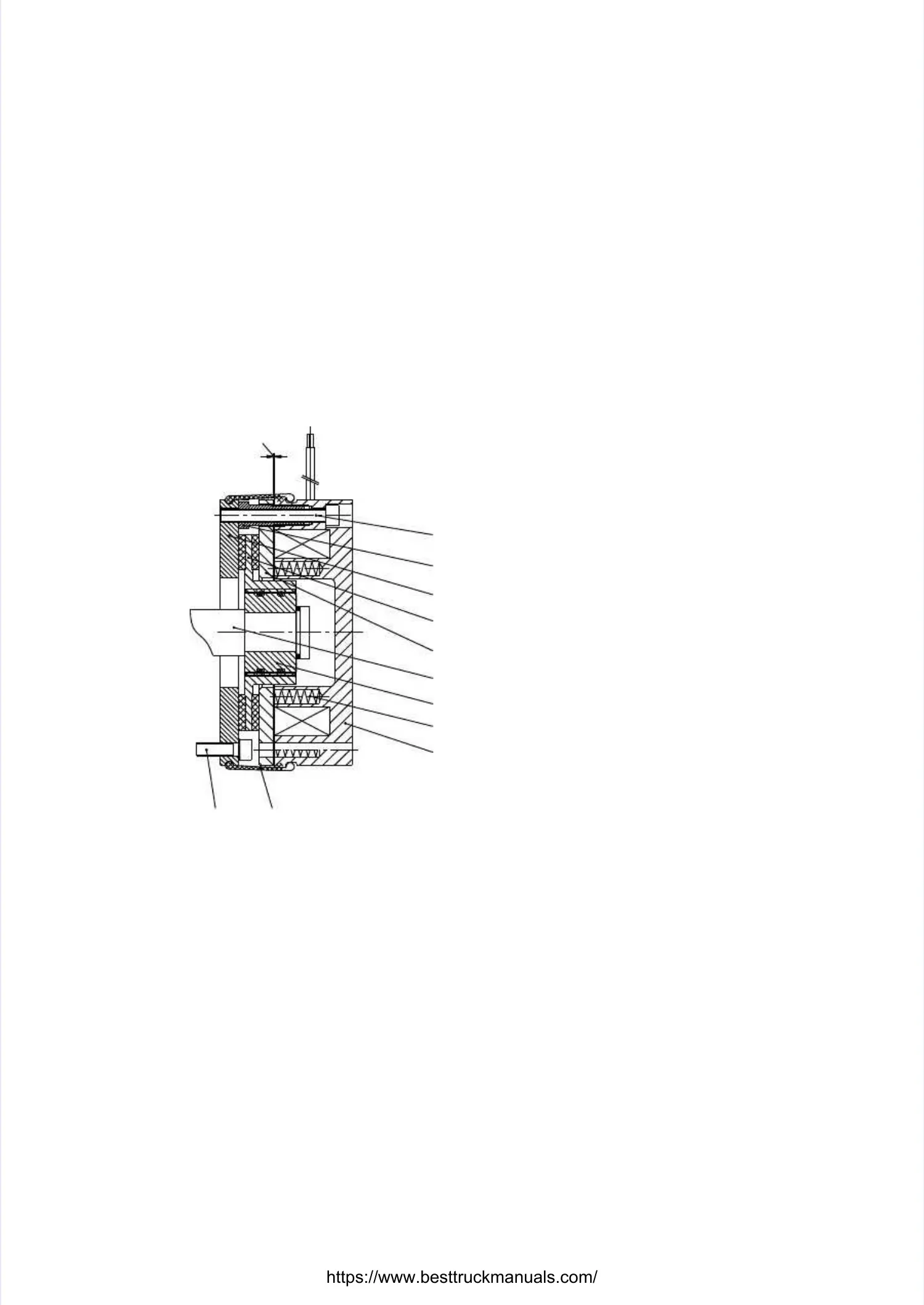

1.5.1 Electromagnetic brake working principle1.5.1 Electromagnetic brake working principle

Motor shaft (9) is connected with shaft sleeve (4) by passing through the flat key. And shaftMotor shaft (9) is connected with shaft sleeve (4) by passing through the flat key. And shaft

sleeve (4) is connected with brake pad (3) by passing through the splines. When the stator (11) issleeve (4) is connected with brake pad (3) by passing through the splines. When the stator (11) is

block out, the block out, the force produforce produced by the ced by the pressure spressure spring (10pring (10) ) would act on would act on the armaturthe armature (8) whe (8) whichich

makes rotated the brake pad (3) driven by the motor shaft connected closely between themakes rotated the brake pad (3) driven by the motor shaft connected closely between the

armature (8) and cover plate (5). As a armature (8) and cover plate (5). As a result the braking torque is created. There will be result the braking torque is created. There will be a air gapa air gap

Z between the armature and the stator at that Z between the armature and the stator at that moment. When the brake needs to be moment. When the brake needs to be relaxed, therelaxed, the

stator is applied with direct current and the magnetic field would attract the armature (8) to movestator is applied with direct current and the magnetic field would attract the armature (8) to move

towards the stator. The movement of armature compresses the pressure spring (10) which causetowards the stator. The movement of armature compresses the pressure spring (10) which cause

the loosening of the brake pad (3) by that time and the brake is released.the loosening of the brake pad (3) by that time and the brake is released.

1.Mounting Bolt of the Brake1.Mounting Bolt of the Brake

3. Brake Pad3. Brake Pad

4. Shaft Sleeve4. Shaft Sleeve

5. Friction Disk5. Friction Disk

6. Dustproof Cover6. Dustproof Cover

7. Hollow Screw7. Hollow Screw

8. Armature8. Armature

9. Motor Shaft9. Motor Shaft

10.Pressure Spring10.Pressure Spring

11.Stator11.Stator

12.Mounting Bolt of Friction Disk12.Mounting Bolt of Friction Disk

Z. Air GapZ. Air Gap

Fig.2-4 Fig.2-4 ElectromagnetElectromagnetic ic BrakeBrakeStructureStructure

Loading...

Loading...