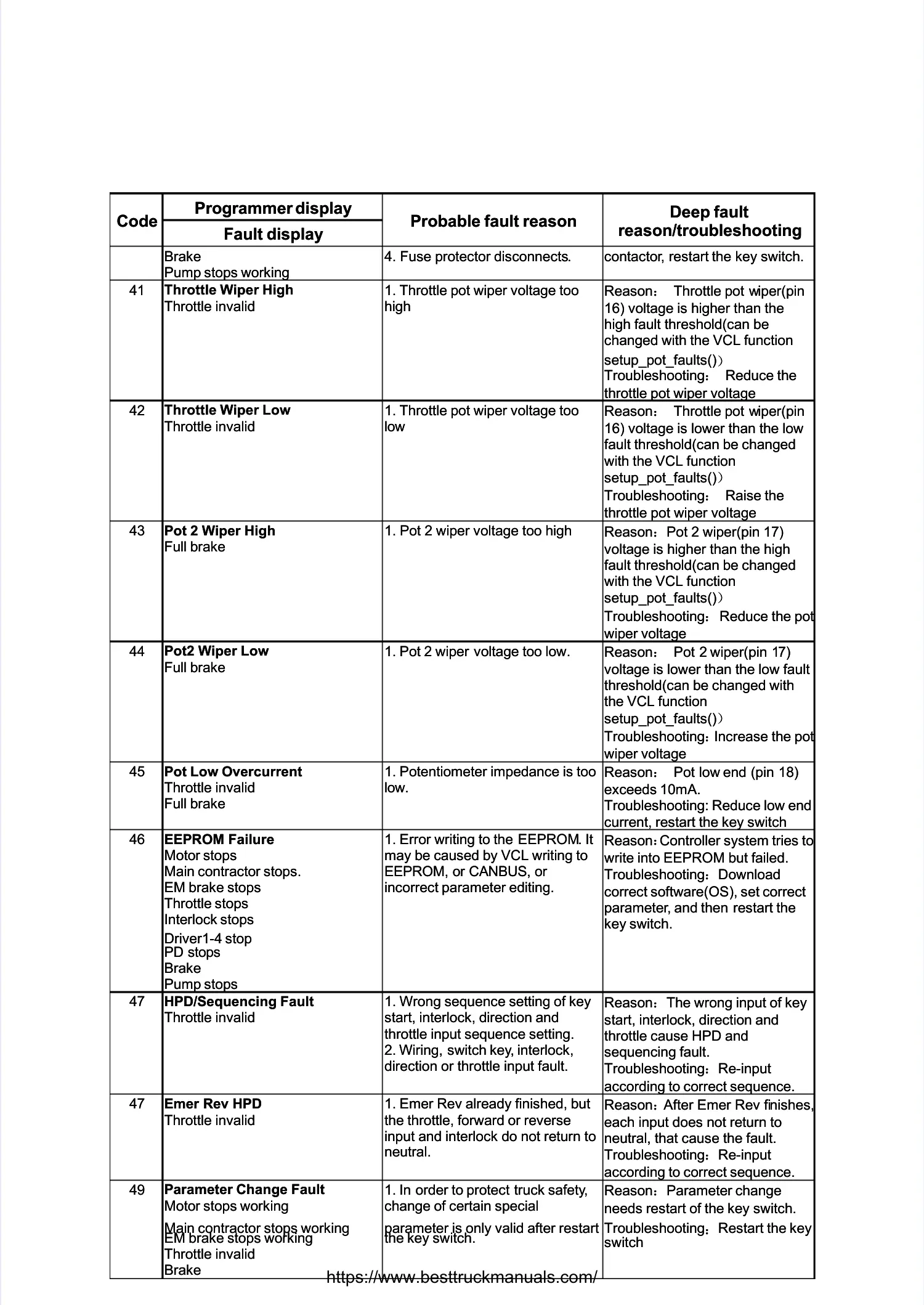

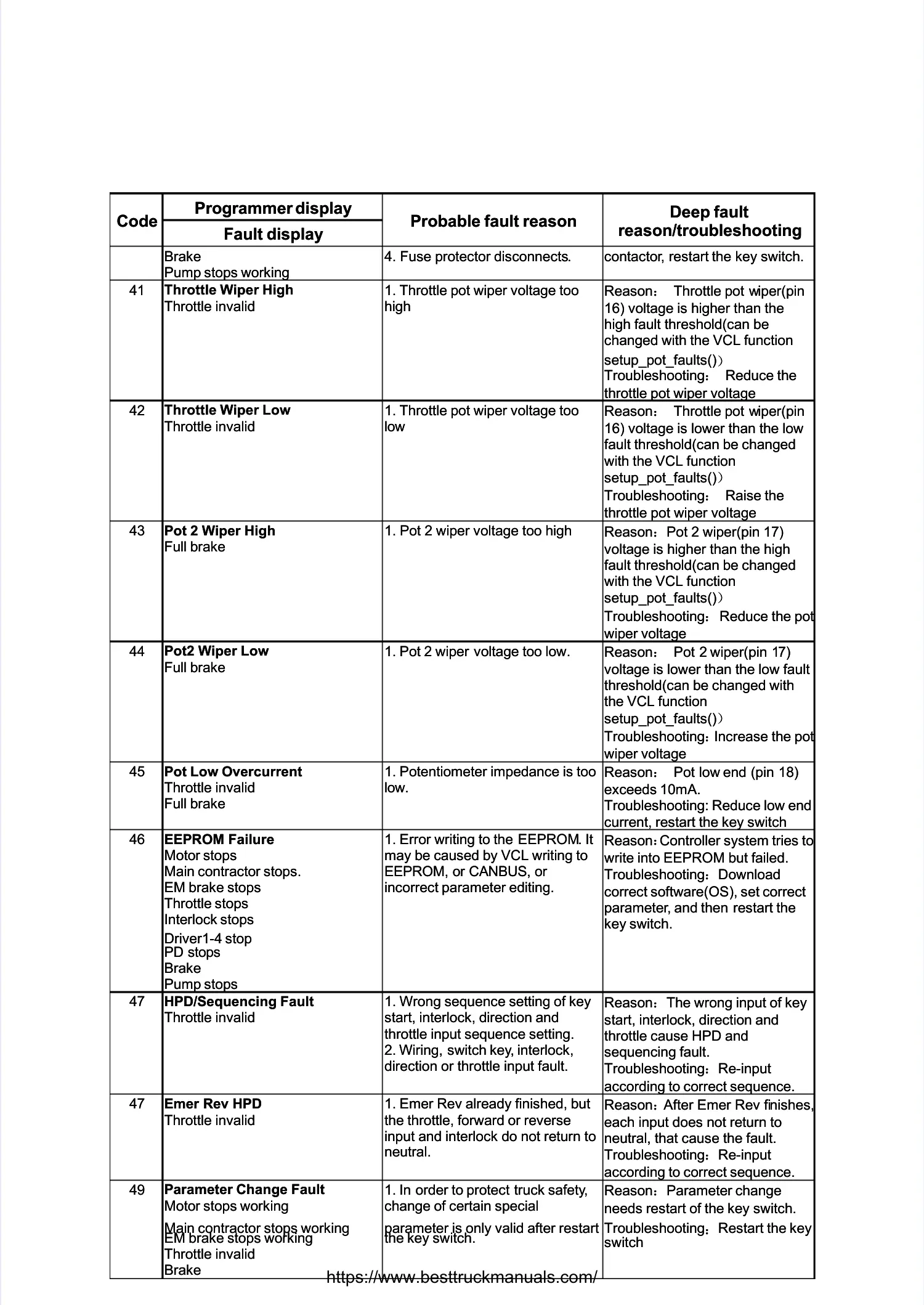

CodeCode

Programmer displayProgrammer display

Probable fault reasonProbable fault reason

Deep faultDeep fault

reason/troubleshootingreason/troubleshooting

Fault displayFault display

BrakeBrake

Pump stops workingPump stops working

4. 4. Fuse Fuse protector protector disconnectsdisconnects. . contactorcontactor, , restart restart the the key key switch.switch.

4141

Throttle Wiper HighThrottle Wiper High

Throttle invalidThrottle invalid

1. Throttle pot wiper voltage too1. Throttle pot wiper voltage too

highhigh

ReasonReason:: Throttle Throttle pot wpot wiper(piniper(pin

16) voltage is higher than the16) voltage is higher than the

high fault threshold(can behigh fault threshold(can be

changed with the VCL functionchanged with the VCL function

setup_pot_faults()setup_pot_faults()

))

TroubleshootingTroubleshooting:: Reduce Reduce thethe

throttle pot wiper voltagethrottle pot wiper voltage

4242

Throttle Wiper LowThrottle Wiper Low

Throttle invalidThrottle invalid

1. Throttle pot wiper voltage too1. Throttle pot wiper voltage too

lowlow

ReasonReason

::

Throttle Throttle pot wpot wiper(piniper(pin

16) voltage is lower than the low16) voltage is lower than the low

fault threshold(can be changedfault threshold(can be changed

with the VCL functionwith the VCL function

setup_pot_faults()setup_pot_faults()))

TroubleshootingTroubleshooting:: Raise Raise thethe

throttle pot wiper voltagethrottle pot wiper voltage

4343

Pot 2 Wiper HighPot 2 Wiper High

Full brakeFull brake

1. Pot 2 wiper voltage too high1. Pot 2 wiper voltage too high

ReasonReason::Pot 2 wiper(pin 17)Pot 2 wiper(pin 17)

voltage is higher than the highvoltage is higher than the high

fault threshold(can be changedfault threshold(can be changed

with the VCL functionwith the VCL function

setup_pot_faults()setup_pot_faults()

))

TroubleshootingTroubleshooting:: Reduce the potReduce the pot

wiper voltagewiper voltage

4444

Pot2 Wiper LowPot2 Wiper Low

Full brakeFull brake

1. Pot 2 wiper 1. Pot 2 wiper voltage too low.voltage too low.

ReasonReason

::

Pot 2 Pot 2 wiper(pin 1wiper(pin 17)7)

voltage is lower than the low faultvoltage is lower than the low fault

threshold(can be changed withthreshold(can be changed with

the VCL functionthe VCL function

setup_pot_faults()setup_pot_faults()))

TroubleshootingTroubleshooting::Increase the potIncrease the pot

wiper voltagewiper voltage

4545

Pot Low OvercurrentPot Low Overcurrent

Throttle invalidThrottle invalid

Full brakeFull brake

1. Potentiometer impedance is too1. Potentiometer impedance is too

low.low.

ReasonReason

::

Pot low Pot low end (pin 18)end (pin 18)

exceeds 10mA.exceeds 10mA.

Troubleshooting: Reduce low endTroubleshooting: Reduce low end

current, restart the key switchcurrent, restart the key switch

4646

EEPROM FailureEEPROM Failure

Motor stopsMotor stops

Main contractor stops.Main contractor stops.

EM brake stopsEM brake stops

Throttle stopsThrottle stops

Interlock stopsInterlock stops

Driver1-4 stopDriver1-4 stop

PD stopsPD stops

BrakeBrake

Pump stopsPump stops

1. Error writing to the 1. Error writing to the EEPROMEEPROM. It. It

may be caused by VCL writing tomay be caused by VCL writing to

EEPROM, or CANBUS, orEEPROM, or CANBUS, or

incorrect parameter editing.incorrect parameter editing.

ReasonReason

::

Controller system tries toController system tries to

write into EEPROM but failed.write into EEPROM but failed.

TroubleshootingTroubleshooting::DownloadDownload

correct software(OS), set correctcorrect software(OS), set correct

parameterparameter, and then , and then restart therestart the

key switch.key switch.

4747

HPD/Sequencing FaultHPD/Sequencing Fault

Throttle invalidThrottle invalid

1. Wrong sequence setting of key1. Wrong sequence setting of key

start, interlock, direction andstart, interlock, direction and

throttle input sequence setting.throttle input sequence setting.

2. Wiring, 2. Wiring, switch keyswitch key, interlock,, interlock,

direction or throttle input fault.direction or throttle input fault.

ReasonReason

::

The wrong input of keyThe wrong input of key

start, interlock, direction andstart, interlock, direction and

throttle cause HPD andthrottle cause HPD and

sequencing fault.sequencing fault.

TroubleshootingTroubleshooting::Re-inputRe-input

according to correct sequence.according to correct sequence.

4747

Emer Rev HPDEmer Rev HPD

Throttle invalidThrottle invalid

1. Emer Rev already finished, but1. Emer Rev already finished, but

the throttle, forward or reversethe throttle, forward or reverse

input and interlock do not return toinput and interlock do not return to

neutral.neutral.

ReasonReason::After Emer Rev fiAfter Emer Rev finishes,nishes,

each input does not return toeach input does not return to

neutral, that cause the fault.neutral, that cause the fault.

TroubleshootingTroubleshooting

::

Re-inputRe-input

according to correct sequence.according to correct sequence.

4949

Parameter Change FaultParameter Change Fault

Motor stops workingMotor stops working

Main contractor stops workingMain contractor stops working

EM brake stops workingEM brake stops working

Throttle invalidThrottle invalid

BrakeBrake

1. In 1. In order to protect order to protect truck safetytruck safety,,

change of certain specialchange of certain special

parameter is only valid after restartparameter is only valid after restart

the key switch.the key switch.

ReasonReason::Parameter changeParameter change

needs restart of the key switch.needs restart of the key switch.

TroubleshootingTroubleshooting

::

Restart the keyRestart the key

switchswitch

Loading...

Loading...