44

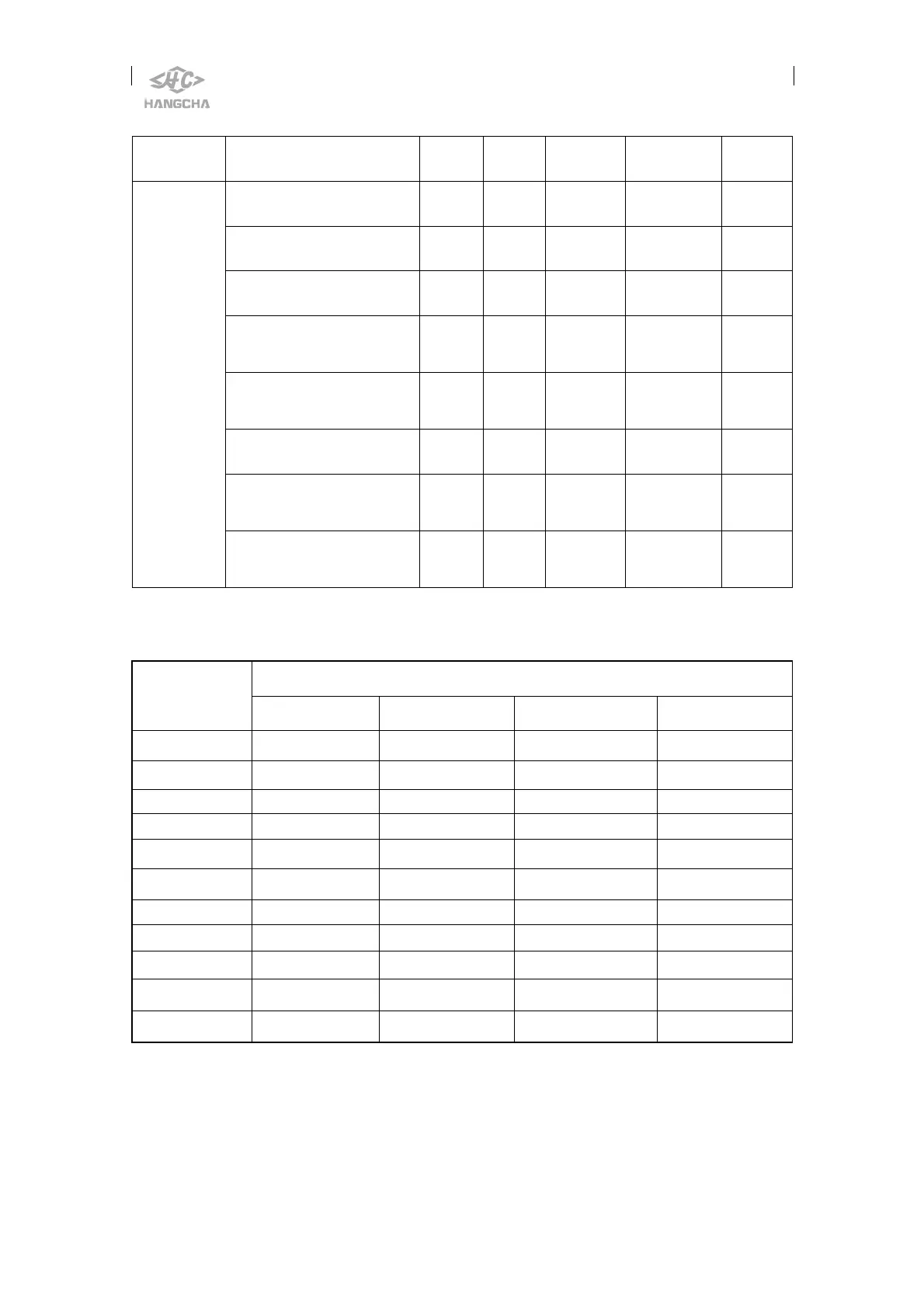

Checking

Item

Service required Tools

Monthly

(180-200hrs)

Trimonthly

(500 hrs)

Semiannually

(1000 hrs)

Annually

(2000hrs)

Check chain for tension ○ ○ ○ ○

Lubrication of chains ○ ○ ○ ○

Check chain and bearing for

damage or deformation

○ ○ ○ ○

Check lifting cylinders for

proper operation and

connection

○ ○ ○ ○

Check tilting cylinders for

proper operation and

connection

○ ○ ○ ○

Check for forks and stopper

pins for damage or wear

○ ○ ○ ○

Check fork base and hook

welding for defective cracks

or wear

○ ○ ○ ○

Lifting

system

Check roller of mast and

lifting bracket parts for

cracks or damage

○ ○ ○

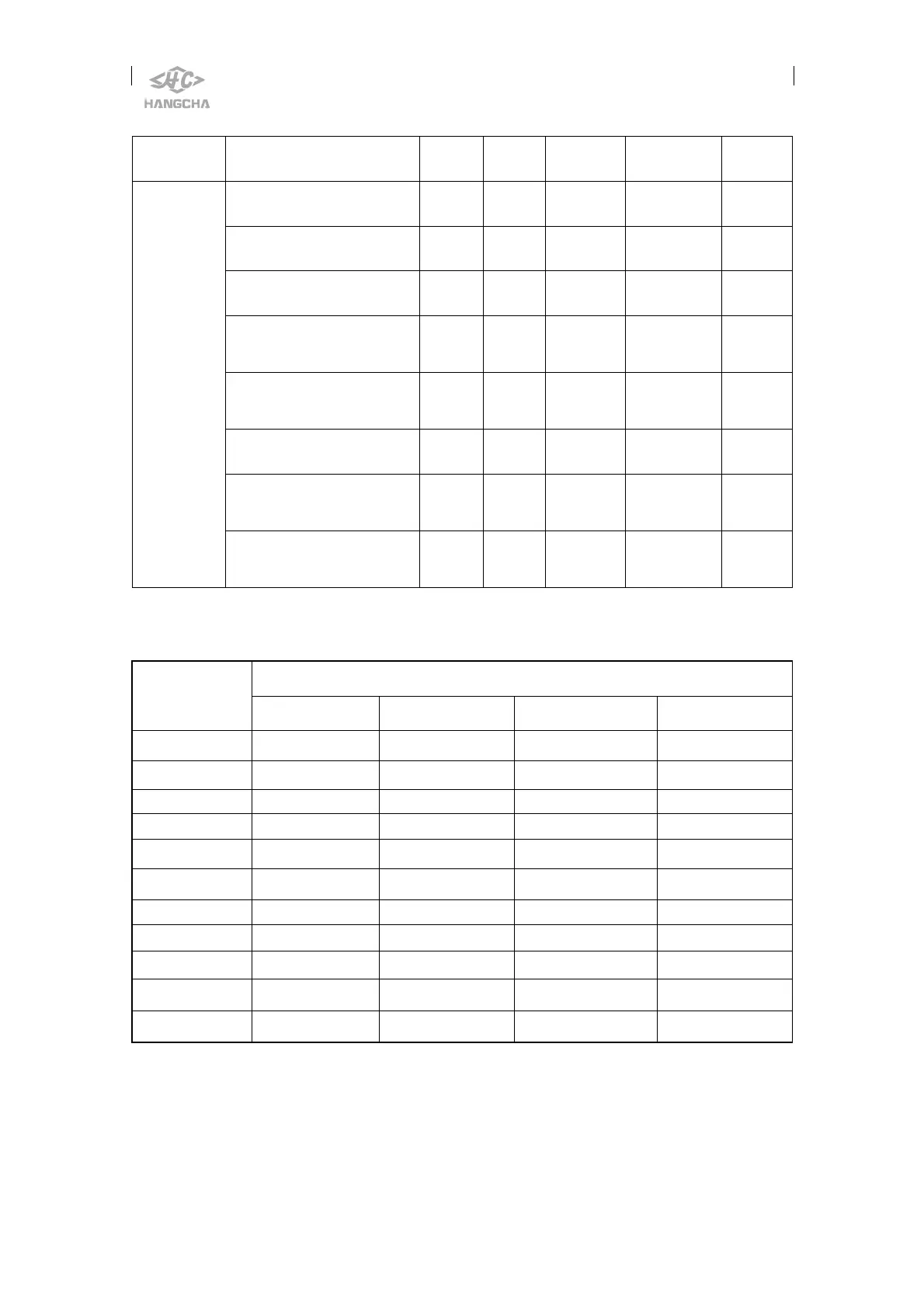

Table for bolt’s tight moment unit:N•m

Grade

Bolt’s

diameter

4.6 5.6 6.6 8.8

6 4~5 5~7 6~8 9~12

8 10~12 12~15 14~18 22~29

10 20~25 25~31 29~39 44~58

12 35~44 44~54 49~64 76~107

14 54~69 69~88 83~98 121~162

16 88~108 108~137 127~157 189~252

18 118~147 147~186 176~216 260~347

20 167~206 206~265 245~314 369~492

22 225~284 284~343 343~431 502~669

24 294~370 370~441 441~539 638~850

27 441~519 539~686 637~784 933~1244

Note: ·Use entirely 8.8 grade bolt in the important joint position.

·Bolt’s grade can be found in the head of the table, if it can’t be found, the grade is 8.8.

Loading...

Loading...