Page 16 <&(%$*4.8"4,7%H'*#$"&8#I%/7*,#*%4,77%JKLLLKLMMKNOPO1 Item 56825

?@<6AQ D@CEA6E@ER6S@?CR%T6GUCEV T6GUCEV%ACW?SETUP

ACV%T*79"83

AX%W;6!6EA%?6;CXF?%CE`F;Q%@EU%U6@AB-%%%

U&%8&$%)*79%)"$.&'$%V(&'89"83%R7,5/1%%

T.*8%$.*%&/*(,$&(%"#%8&$%.&79"83%$.*%A&(4.I%"$%5'#$%+*%#"$$"83%&8%,%8&84&89'4$"Z*I%8&827,55,+7*%#'(2,4*1%

X87>%.&79%ACV%;&9%)"$.%,8%*7*4$("4,77>%"8#'7,$*9%)*79"83%37&Z*1

%%%

AX%W;6!6EA%U6@AB%<;XD%@?WBQfC@ACXE-%

U&%8&$%&/*8%3,#%)"$.&'$%/(&/*(%Z*8$"7,$"&81%%<"]%3,#%7*,Y#%"55*9",$*7>1 Shielding gas can displace

air and cause rapid loss of consciousness and death. ?."*79"83%3,#%)"$.&'$%4,(+&8%9"&]"9*%4,8%+*%

*Z*8%5&(*%.,\,(9&'#%+*4,'#*%,#/.>]",$"&8%4,8%#$,($%)"$.&'$%2**7"83%#.&($8*##%&2%+(*,$.1

EXACR6-% TIG welding is a complicated process,

requiring experience and skill to achieve

successful results. Training beyond the scope of

this manual is required to TIG weld properly.

1. Open gas cylinder’s valve all the way.

2. Set Flow Gauge to SCFH value indicated

on Settings Chart on top of Welder.

3. Turn the Power Switch to the OFF position, then

plug the Welder into a properly grounded, GFCI

SURWHFWHG9$&DPSUDWHGRXWOHWRU

9$&UHFHSWDFOHWKDWPDWFKHVWKHSOXJ

The circuit must be equipped with delayed

action-type circuit breaker or fuses.

4. Set TIG Torch down on nonconductive,

nonflammable surface well away

from any grounded objects.

5. Turn the Power Switch ON.

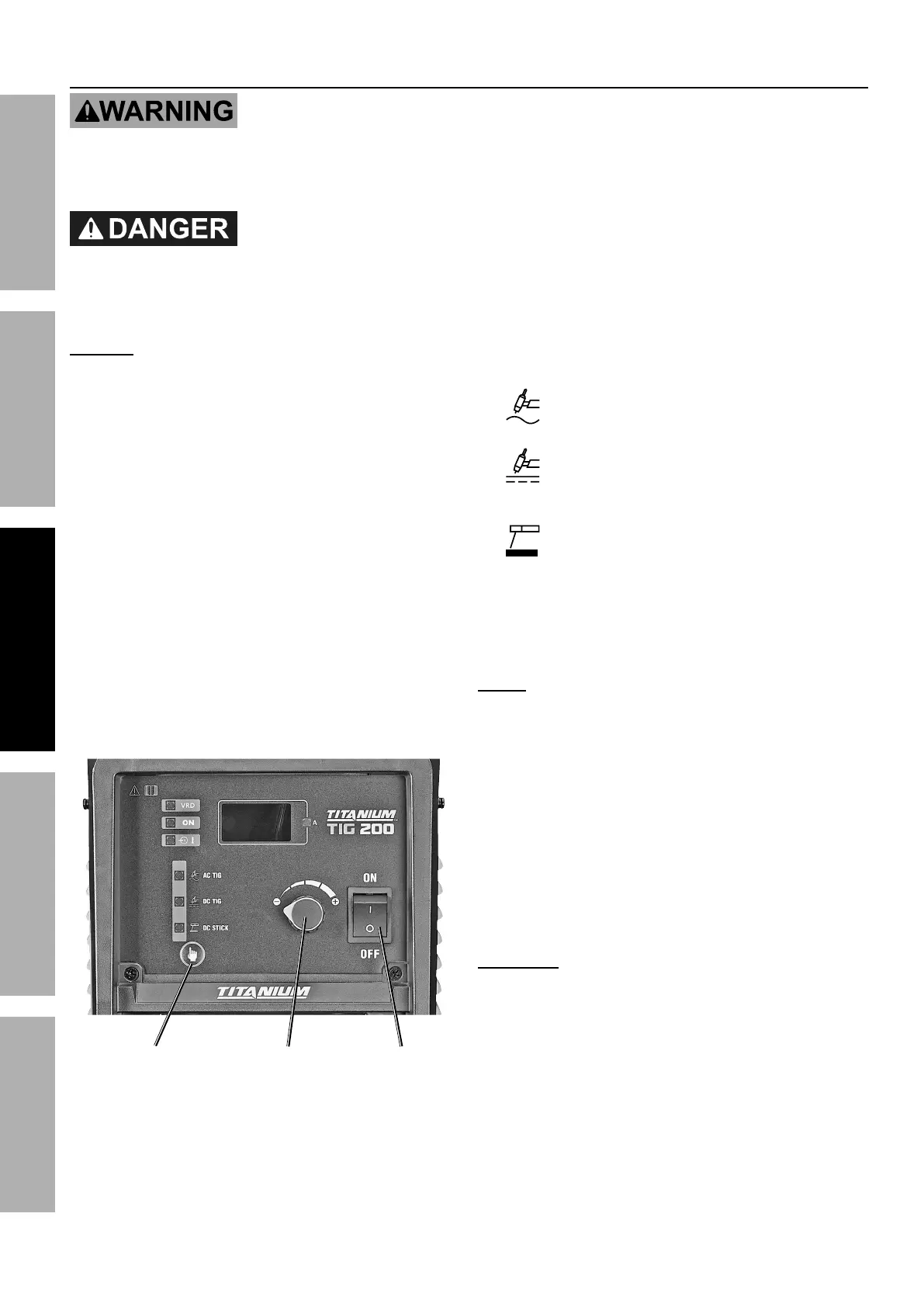

R'((*8$%

X'$/'$%[8&+

T*79"83%

D&9*%?)"$4.

W&)*(%

?)"$4.

6. ?*7*4$%W(&4*##- Press Welding Mode

Switch to scroll to desired welding mode.

@R%ACV%K%<&(%)*79"83%,7'5"8'5

%%UR%ACV%K%<&(%)*79"83%

5"79%,89%#$,"87*##%#$**7

%%UR%?ACR[%K%V&%$&%?$"4Y%

T*79"83%&8%/,3*%JL1

7. Set amperage according to Settings Chart on top

of Welder. Set to high end of amperage range.

For example: Range is 80-100A,

set amperage to 100A.

EXA6- Amperage settings are

approximate. Adjust as necessary.

Other parameters like AC balance, pre-gas flow

time and post-gas flow time have been preset:

• Pre-Flow: The number of seconds that gas

ZLOOIORZRQFHWKH)RRW3HGDOLVSXVKHG±WKLV

is preset at 0.3 seconds. The arc will not start

for that preset time, but gas will flow. Once

the preset time expires, the arc will start.

• Post-Flow: The number of seconds that gas

will flow once the Foot Pedal is released. This

has been preset and automatically adjusts

based on the preset amperage output.

T@;ECEVc%%AX%W;6!6EA%?6;CXF?%CE`F;Q-%%

W(&$*4$"Z*%3*,(%5'#$%+*%)&(8%).*8%'#"83%$.*%

T*79*(d%5"8"5'5%#.,9*%8'5+*(%J^%2'77%2,4*%#."*79%

RUZHOGLQJPDVNHDUSURWHFWLRQZHOGLQJJORYHV

#7**Z*#%,89%,/(&8I%ECX?BK,//(&Z*9%(*#/"(,$&(I%

,89%2"(*%(*#"#$,8$%)&(Y%47&$.*#%)"$.&'$%/&4Y*$#%

#.&'79%+*%)&(8%).*8%)*79"831%%G"3.$%2(&5%$.*%

,(4%4,8%4,'#*%/*(5,8*8$%9,5,3*%$&%$.*%*>*#%

,89%#Y"81%%U&%8&$%+(*,$.*%,(4%2'5*#1

Loading...

Loading...