13

GENERATOR TRAY

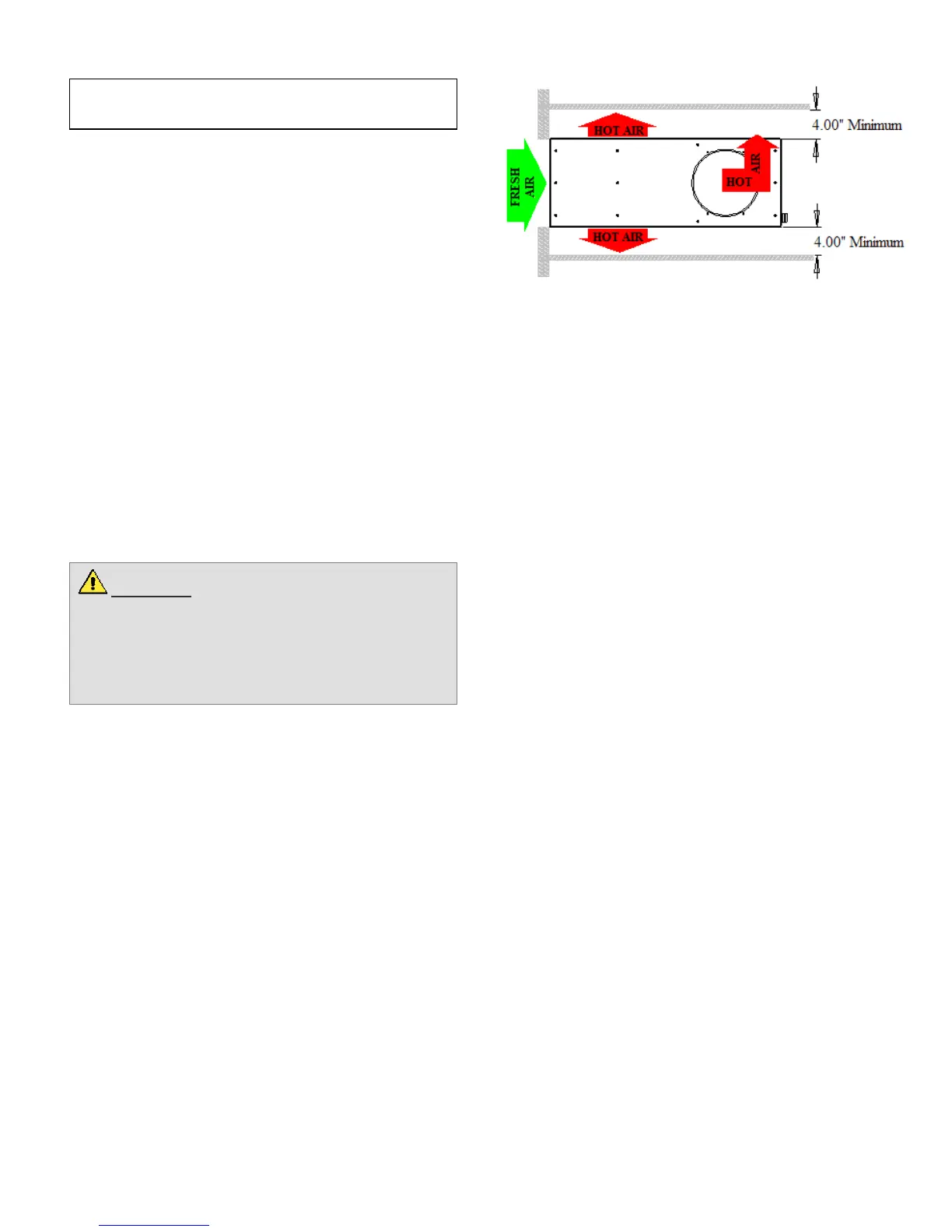

MOUNTING AND AIRFLOW

The generator tray is constructed of 11 gauge steel

that has been powder coated for protection from the

elements. When choosing a mounting location for the

generator tray unit, take into account the following

factors:

• Airflow and ventilation, 176 sq. in. inlet area

• Protection from debris and water

• Service and weight constraints

The most important factor to consider when

mounting the tray unit is the air ventilation. The

minimum distance between the nearest wall to both

the intake and exhaust is 4 inches. Also, arrange the

unit so that the exhaust air does not re-circulate into

the inlet.

CAUTION!

SUPPLY THE GENERATOR TRAY WITH ENOUGH

FRESH AIR AT THE INLET. ALSO, THE HOT

EXHAUST AIR NEEDS AN ADEQUATE OUTLET

SO IT DOES NOT CIRCULATE INTO THE INLET.

Figure 10 shows example of bad and good air flow

installations. An intake shroud may be necessary for

certain installations. If the system oil temperature

exceeds 180°F, check the inlet and exhaust for

restrictions. If the inlet air temperature is above

120°F, this may be an indication that the hot exhaust

air is re-circulating into the intake and additional

baffling is necessary.

Figure 9: Good Generator Airflow Installation

An installation with good airflow allows at least

4.00” of space around the unit for the exhaust air to

evacuate properly. A shroud or an air deflector is

used in cases were re-circulation is possible.

Generally, all alternators cool the same way. Fresh

air is pulled in one end of the rotor/stator assembly

and exhausted out the other end. It is important to

keep out road salt, dirt, snow, water, and other

contaminates. Another consideration is high water

crossings. Inspect the tray assembly on a regular

basis. If any generator system is submerged in water,

it will destroy the electrical components unless it is

completely dried before use. Contact the Harrison

factory for more information.

Loading...

Loading...