5 | P a g e

the pipe section is depressurized during installation.

additional information provided in the instructions of the drive are observed, particularly those

referring to the adjustment of the OPEN and CLOSED positions prior to the installation of the

fitting into the pipe section.

B3 Pressure, Direction of Flow and Installation Location

With the fitting opened (P1=P2), the pressure must be limited to the value

indicated as max. permissible pressure on the type plate.

With the fitting closed , the differential pressure P = (P1-P2) may not exceed the

value. (Fig. 2)

B4 Supporting the Fitting in Special Cases

The weight of the module and drive of the fitting can cause deformations and functional problems,

particularly in case of installation into oblique or vertical lines. To avoid this, the valve and drive must

then be supported on part of the building site.

If vibrations and/or pipe forces are transmitted by the pipeline, which could adversely affect the

functioning of the valve, the valve must also be supported.

Details and execution of this support are the responsibility of the user.

B5 Installation Steps

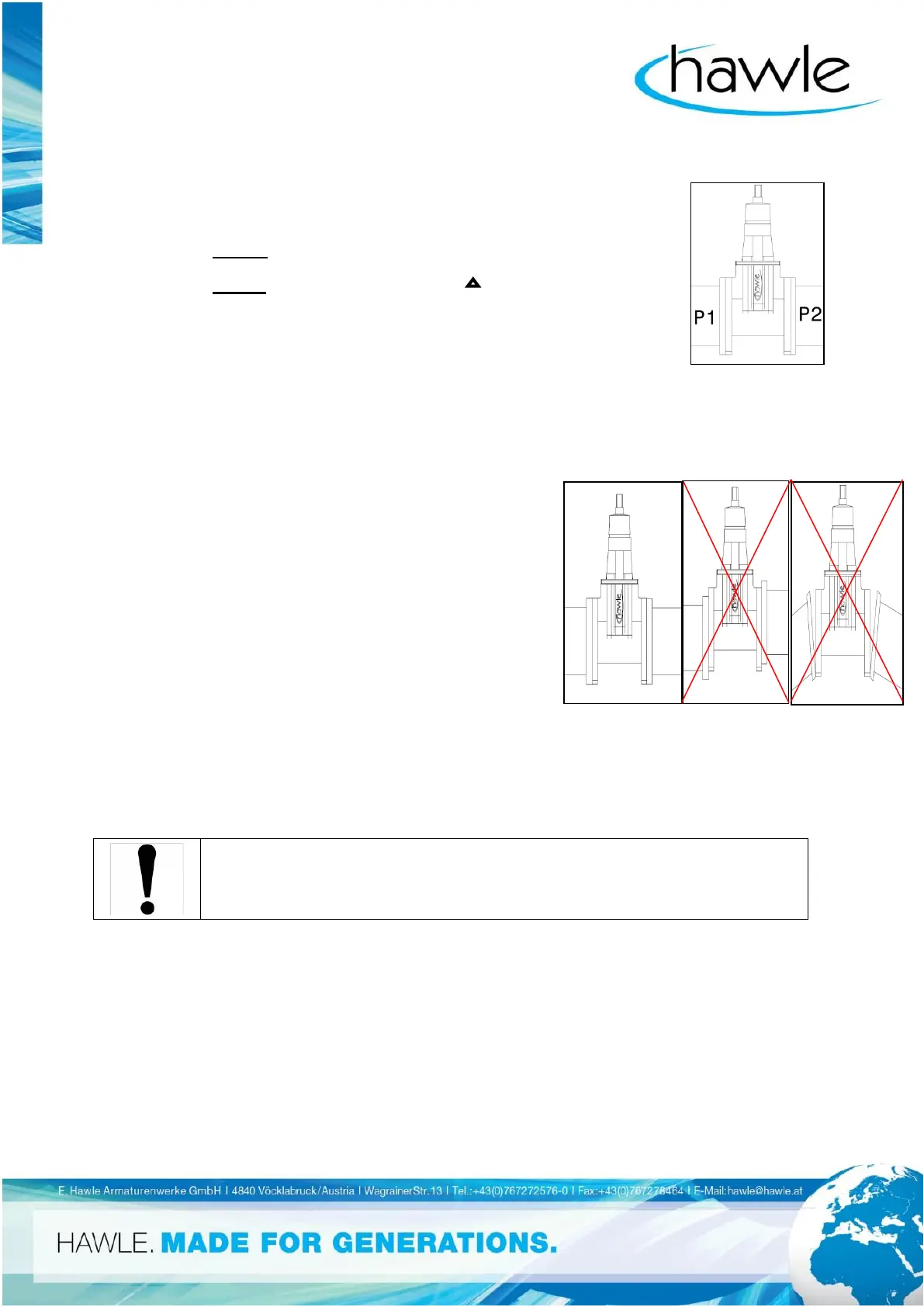

It must be ensured in accordance with Fig. 3 that

the valve and the two opposing

pipe ends are flush

and the sealing surfaces of valve and

pipeline flange are exactly parallel.

If this is not observed, the valve could be damaged through erosion

and/or dead spaces can form in front of or behind the

fitting where deposits may collect, which

could prevent tight closure of the fitting and cause corrosion

on the valve itself.

1. Insert flange seals between valve and counterflanges and center them exactly. The sealing

must cover the working strip for the flange seal fully.

2. Lightly grease the flange screws: this makes it easier to tighten and later loosen the nuts.

Use screw dimensions in accordance with HAWLE catalog sheet and depending on

used counterflanges.

3. First hand-tighten the screws all around, then tighten them evenly in a crosswise fashion (see

Fig. 4 and Catalog).

4. Consider the following tightening torques for galvanized St 4.8 steel screws (non-lubricated):

Loading...

Loading...