9 | P a g e

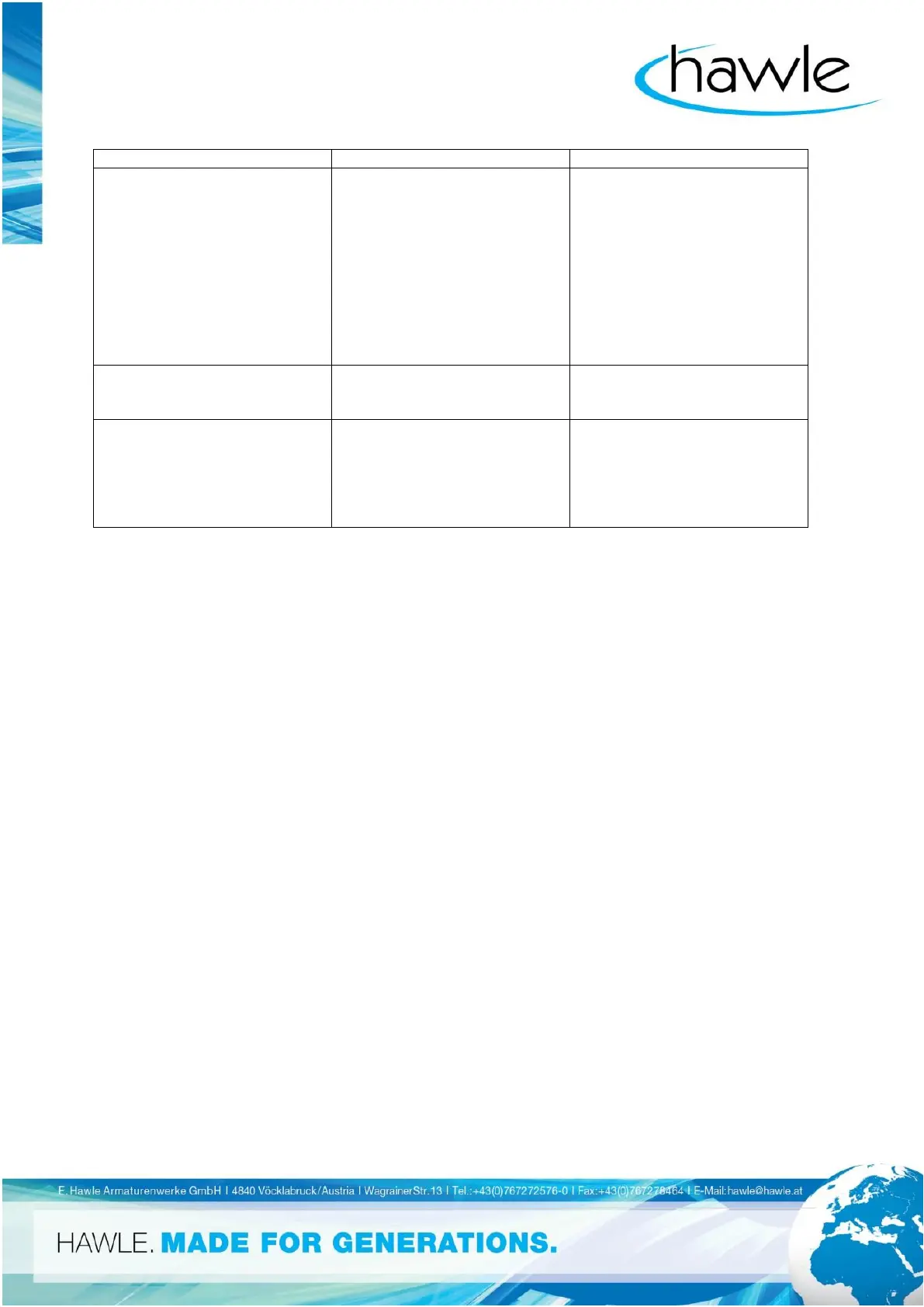

C4 Troubleshooting

Leakage of flange connection

Incorrect length of flange

screws

Flange screws not properly

tightened

Valve not centered correctly

Flange sealing surfaces

between pipeline/fitting not

exactly parallel

Flange sealing not correctly

centered

Incorrect flange sealing material

See this Instruction Manual,

Section B5

Wedge not closing 100 %

Damaged wedge

See supplied drive instruction

manual

Replace wedge

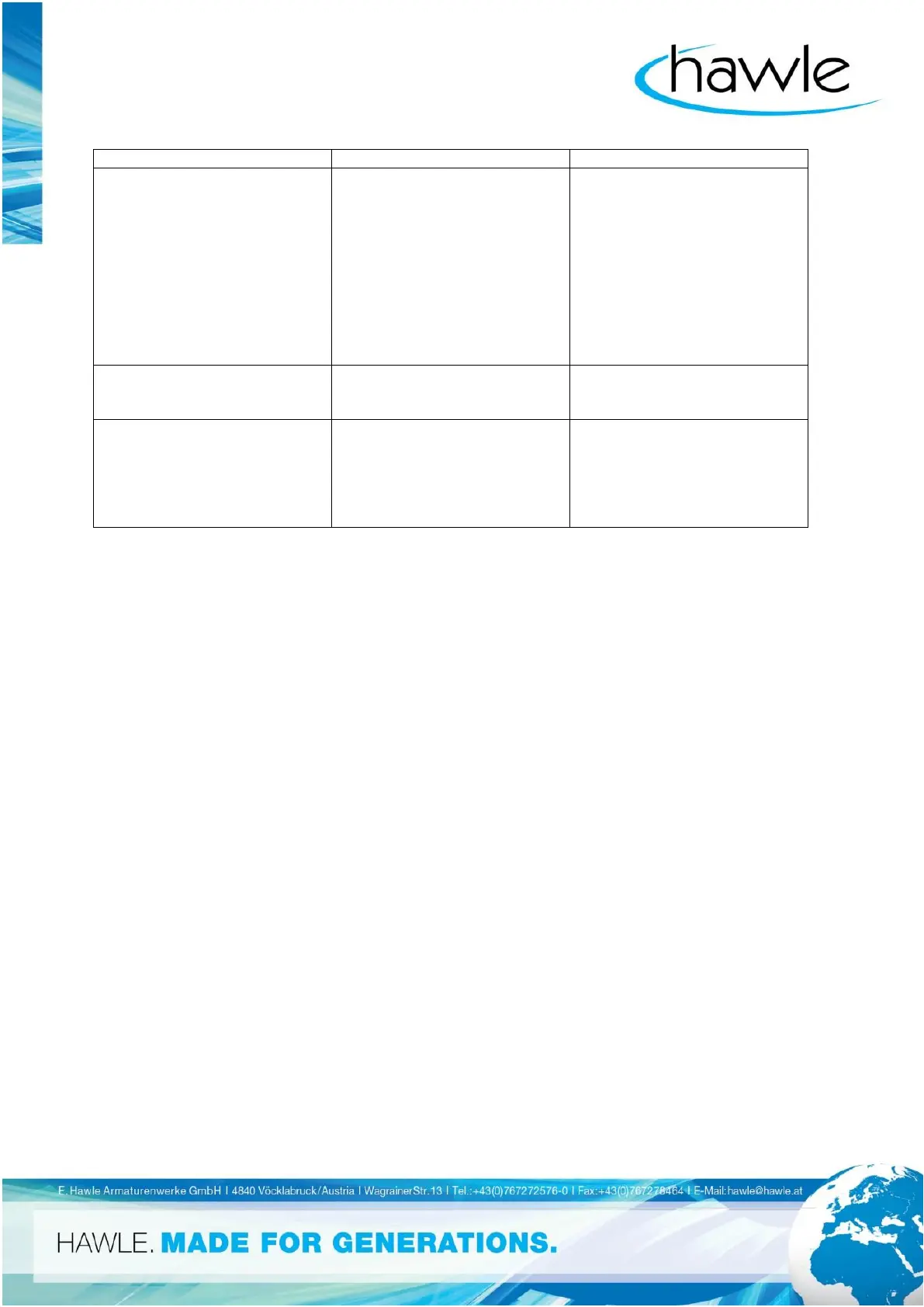

Plate does not open/close

100 %

Drive fault

Drive circuit fault (provided end

switch or mechanical stop)

Wedge leaking due to deposits

Wedge mechanically damaged

Wedge nut worn

See supplied drive instruction

manual

Replace wedge nut

Relubricate spindle

If replacement parts are used for maintenance/repairs that are not original Hawle replacement parts

and/or the instructions regarding operation, maintenance and repairs are not observed by the user,

Hawle Armaturenwerke GmbH will not provide a warranty for damages to the fitting.

Loading...

Loading...