USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

4

Cell

Vessel

FROM

POOL

TO

POOL

Filter

Heater

Filter

Pump

GFCI

Outlet

15 ft

ballast

cable

interlock

cable

flow

switch

cable

6 ft

9 ft

9 ft

120

VAC

Check

Valve

Bypass

NOTE: A check valve is not

necessary for salt chlorination

systems but must be installed

when using chlor ine erosion

feeders. Chlorination must take

place “downstream of the Cell

Vessel.

Inlet

3-Way

Valve

Mounting the Controller

The controller is designed to mount vertically on a flat surface with the cables facing downward. Because the enclosure also acts as a heat sink (disperses heat

from inside the box), it is important not to block the four sides of the controller. Do not mount the controller inside a panel or tightly enclosed area. If the supply

or a lamp cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid a hazard.

After ensuring that the controller’s cables can reach their destinations, mount the controller to the intended surface using proper mounting hardware given the

size and weight of the unit. The controller’s mounting brackets require a total of 6 mounting bolts to fasten the controller to the mounting surface.

Plumbing the HydroRite System

Although not required, Hayward recommends that the HydroRite system be plumbed in a dedicated loop that can be bypassed as shown on page 3. A three-way

valve and actuator are supplied for this purpose. If plumbing a bypass, a tee fitting will be required. A bypass will aid in servicing and maintaining the HydroRite.

Note that the increased head of the HydroRite system may affect the performance of water features installed in the pool’s system. A bypass will allow you to

divert water directly to water features although be aware that the HydroRite will not sanitize under these circumstances.

Installation of 3-way valves on BOTH the inlet and outlet lines attached to the vessel plumbing is mandatory if an automatic vessel cleaner is used, or if the

vessel and associated plumbing is located below the waterline. Failure to use valves where any portion of the device is below the waterline will not allow the

device to be properly drained which could lead to cracking of the unit if any retained water freezes.

Securing the Vessel

When the vessel installation location has been determined, it should be secured to a concrete or wood base. Four mounting holes are located in the mounting

base of the unit that accommodates ¼ inch diameter bolts to mount the HydroRite unit in place. FAILURE TO PROPERLY SECURE THE UNIT MAY CAUSE NOISE

DUE TO VIBRATION CAUSED BY WATER PASSING THROUGH THE WET CHAMBER. Secure the vessel using bolts and anchors (not supplied) where necessary

and appropriate for your installation.

Plumbing the Vessel

The HydroRite vessel comes with union nuts and tails pre-assembled on

the housing. Remove the Inlet and Outlet nuts and note the orientation of

the orange gaskets when removing union tails. These will need to be put

back together after gluing the union tails to the pool piping.

After cutting pipe to length, slide one union nut onto the cut pipe and

glue the gray tail piece to the pipe end. Repeat for the other pipe. Thread

the union nuts onto the vessel and handtighten both unions. DO NOT

OVERTIGHTEN. OVERTIGHTENING WILL BREAK THE UNION NUTS. To avoid

stress on the connections at the vessel, piping should be supported and

should not rest solely upon the unions.

Plumbing the Flow Switch

The flow switch is a safety device that ensures that the HydroRite is only operating when there is water passing through the vessel. The flow switch must be

plumbed in the same section of plumbing as the vessel. Failure to properly install the flow switch can result in damage to the pool’s equipment.

IMPORTANT: There must be at least a 12” (30cm) straight pipe run before (upstream) the flow switch.

IMPORTANT: To ensure proper operation, verify that the arrow on the flow switch points in the direction of water flow.

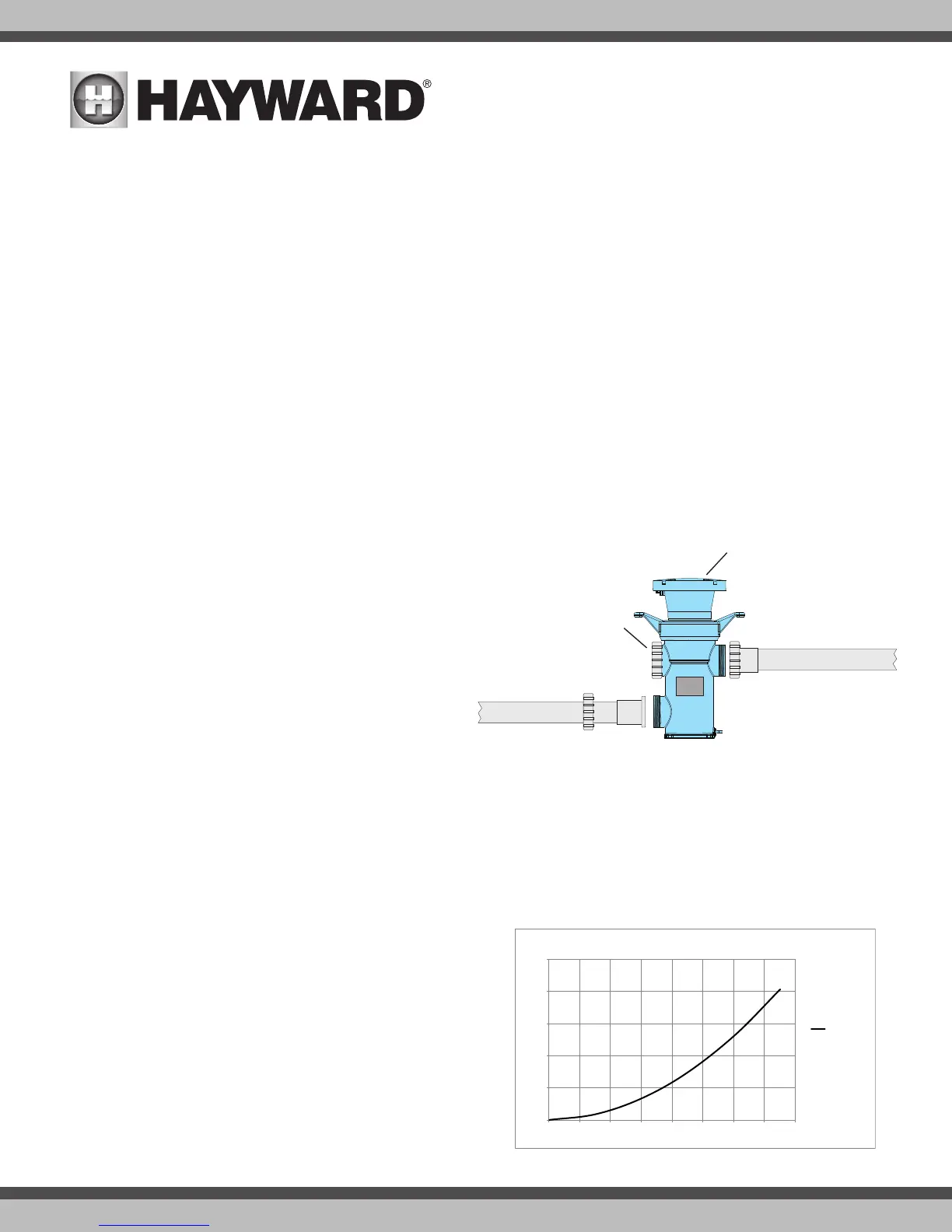

Head Loss

Refer to the adjacent table below for Head Loss information.

0

5

10

15

20

25

0 10 20 30 40 50 60 70 80

Head Loss (Feet of Water)

Flow Rate (GPM)

HydroRite Head Loss

HYR2CSUV-O3

Venturi

The venturi assembly is pre-assembled and ready to be plumbed. A 3 ft

hose connection is made from the venturi to the ozone manifold at the vessel

as shown in the diagram on page 3. More information about the venturi tube

and connection can be found on page 5.

Chlorination Systems

Care must be taken to prevent exposure of the vessel to high concentra-

tions of chlorine. All in-line chlorine systems must be installed AFTER (down-

stream) the vessel.

HYD-UVO

Inlet Pipe

Union

Tail

Union

Nut

Do not

remove

Outlet Pipe

Vessel

Cap

Loading...

Loading...