1

0.0 Changing the saw blade for int. cutting

To make an internal cut in a workpiece with the

m

achine, the workpiece must have an opening in which

you can insert the saw blade. We recommend using the

special clamp for internal cutting.

10.1 Decommission the machine

⇒ 8.4 Decommissioning the machine.

10.2 Fit the special clamp

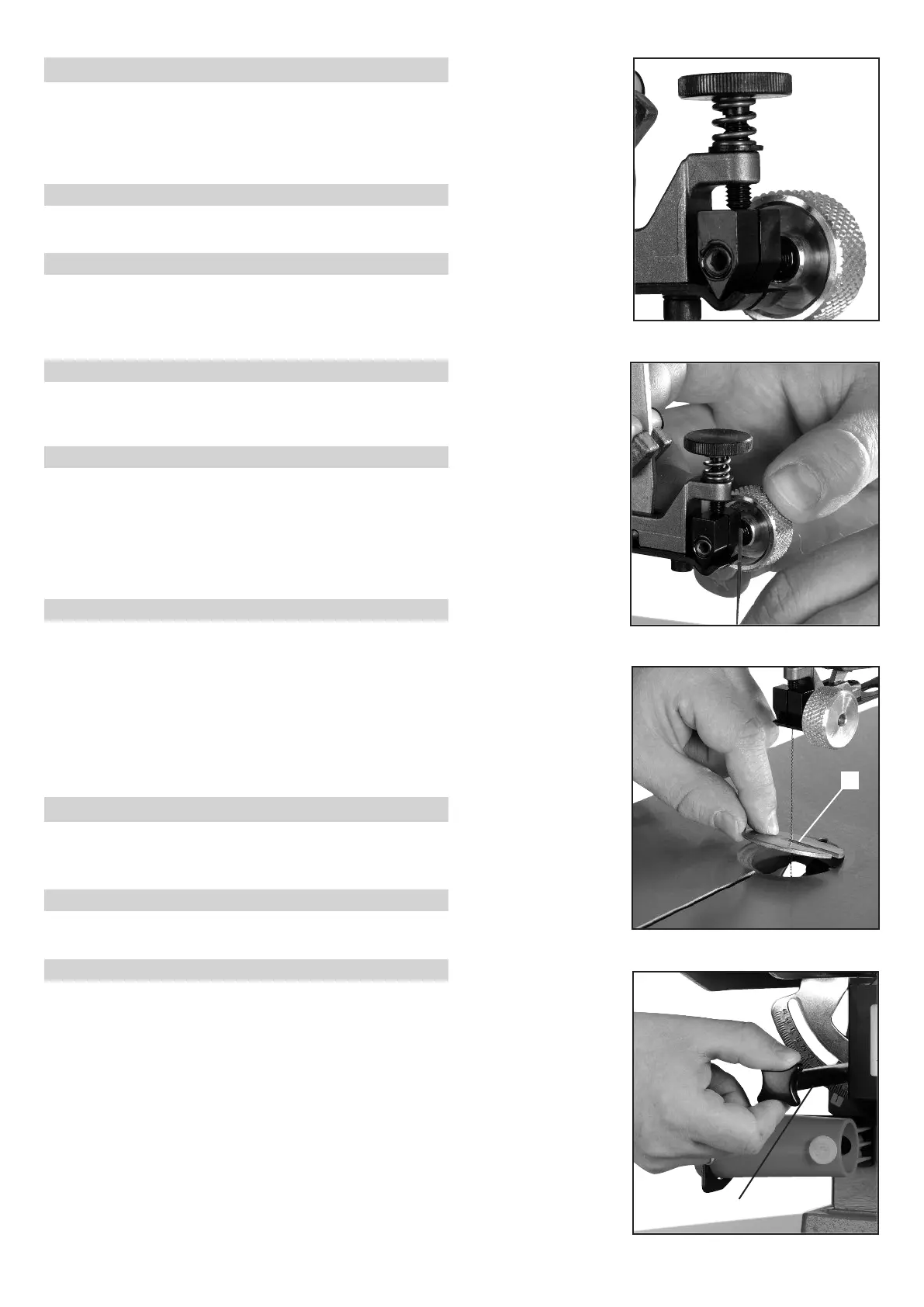

⇒ Fig. 10-1

•

Attach the special clamp in the upper swing arm and

lock with the knurled screw.

10.3 Insert the workpiece

• Push the saw blade to one side until you can guide

the saw blade through the opening of the workpiece.

10.4 Clamp the saw blade

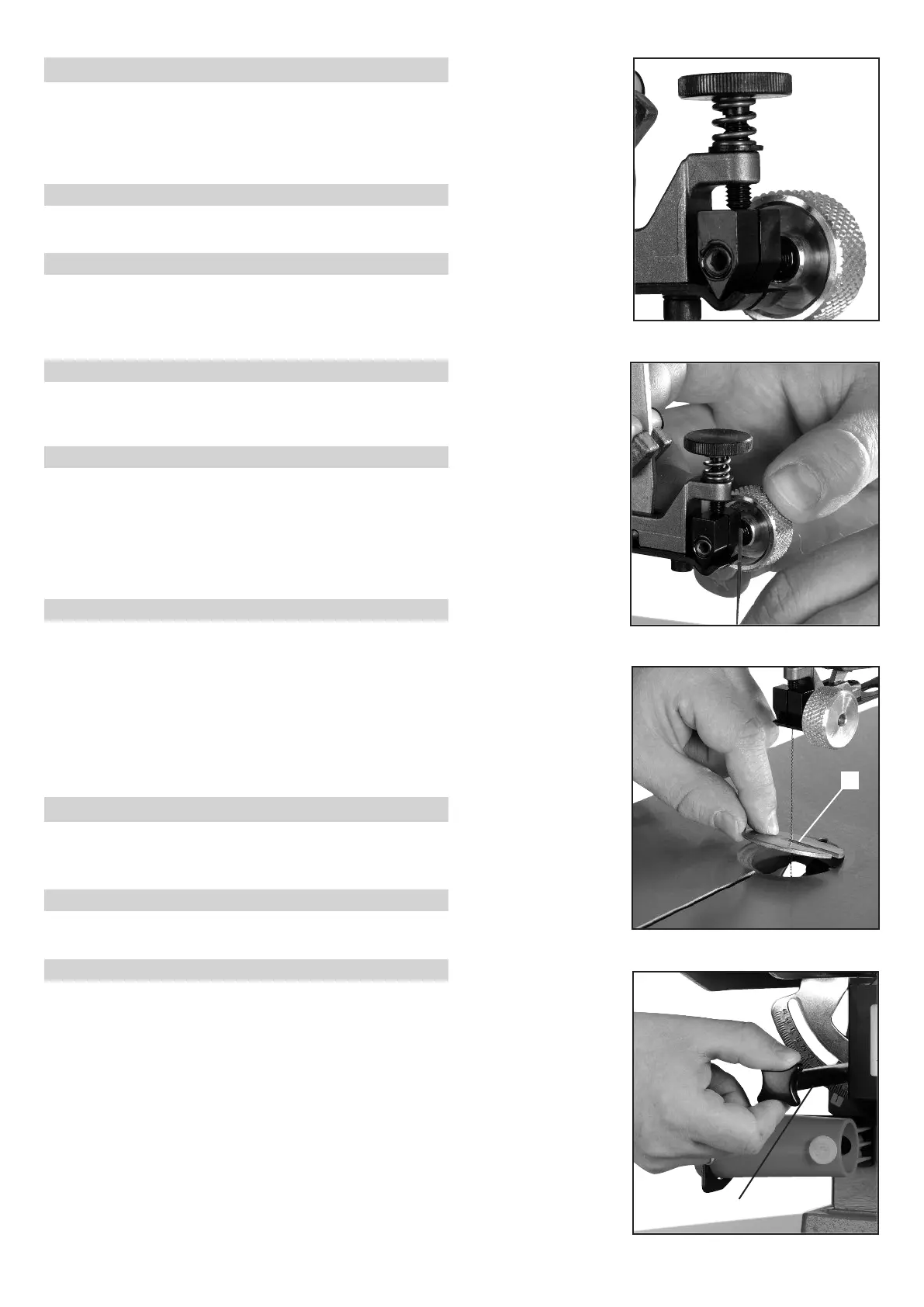

⇒ Fig. 10-2

• From the front, guide the saw blade into the special

clamp, ensuring that the blade does not bend.

• Close the special clamp by twisting the knurled

aluminium screw.

10.5 Tensioning the saw blade

⇒ 8.1.1 Tensioning the saw blade

• Align the workpiece so that when the machine is

switched on, it cannot be touched by the saw blade

and flung out.

Note: When using the special clamp, the knurled

screw must always be locked in position on the top

arm. This will save time when changing the blade.

11.0 Swivelling the table plate

By adjusting the table plate, you can make angled cuts

up to maximum 45º on workpieces.

11.1 Decommission the saw

⇒ 8.4 Decommissioning the saw.

11.2 Swivel table plate

• Turn the table insert (1) Fig. 11-1-1

• Turn the cross-handled screw (2), Fig. 11-1-2,

around one turn anticlockwise.

• Angle the table plate to the required position and

retighten the cross-handled screw.

☞

☞

☞

8

F

ig. 10-1

Fig. 10-2

Fig. 11-1-1

Fig. 11-1-2

1

2

Loading...

Loading...