13.0 Extraction connection

Certain wood types such as chipboards etc.

produce harmful dust emissions during machining.

For this reason the machine must be connected to

a dust extractor. For long and frequent use of the

machine, operating measures must ensure that the

extractor is automatically switched on when the

machine is switched on.

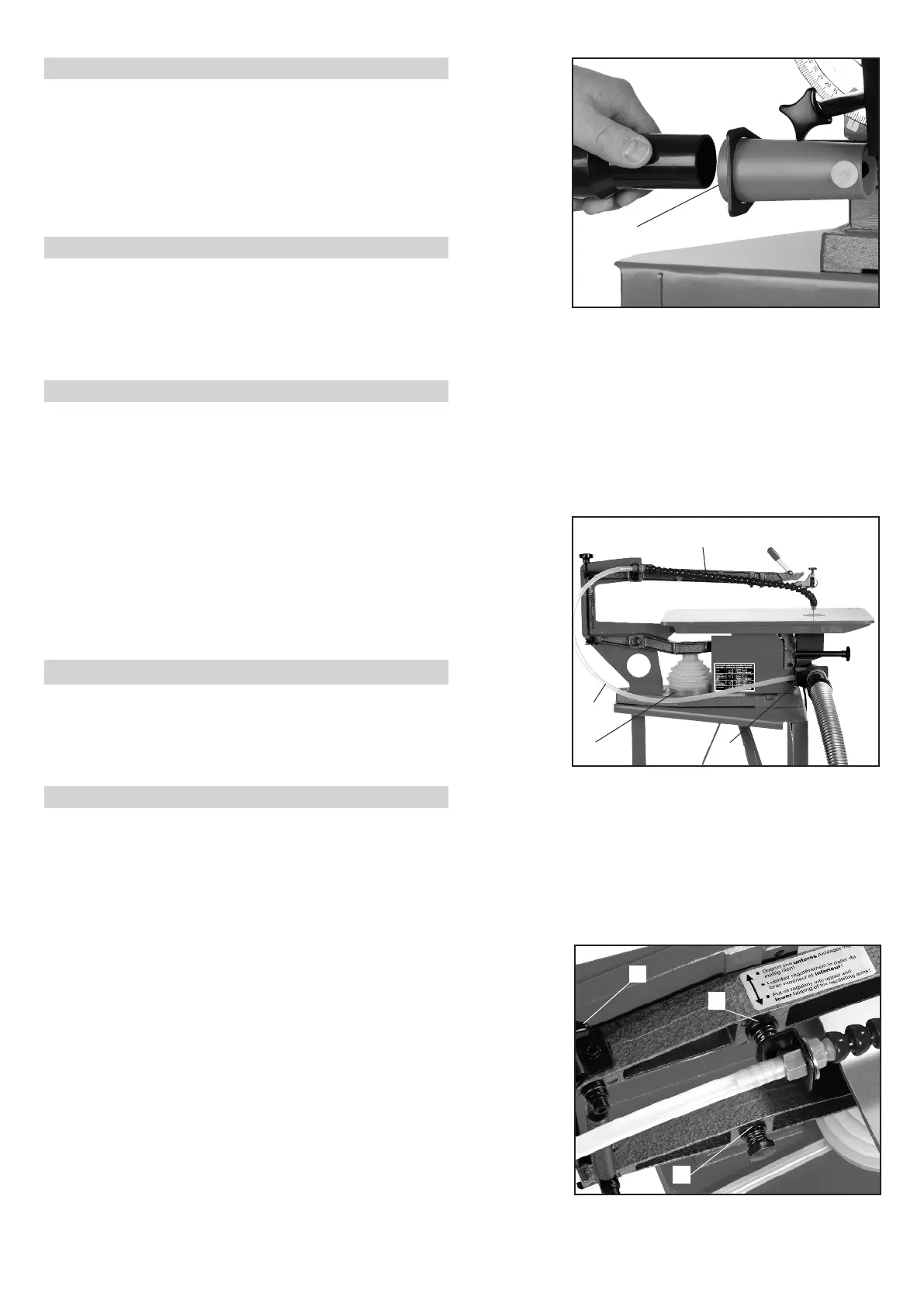

13.1 Connection

⇒ Fig. 13-1

The machine is designed for a standard dust extractor

(vacuum cleaner).

Push the connector of the extractor system into

opening (1) of the connection piece so that it locks.

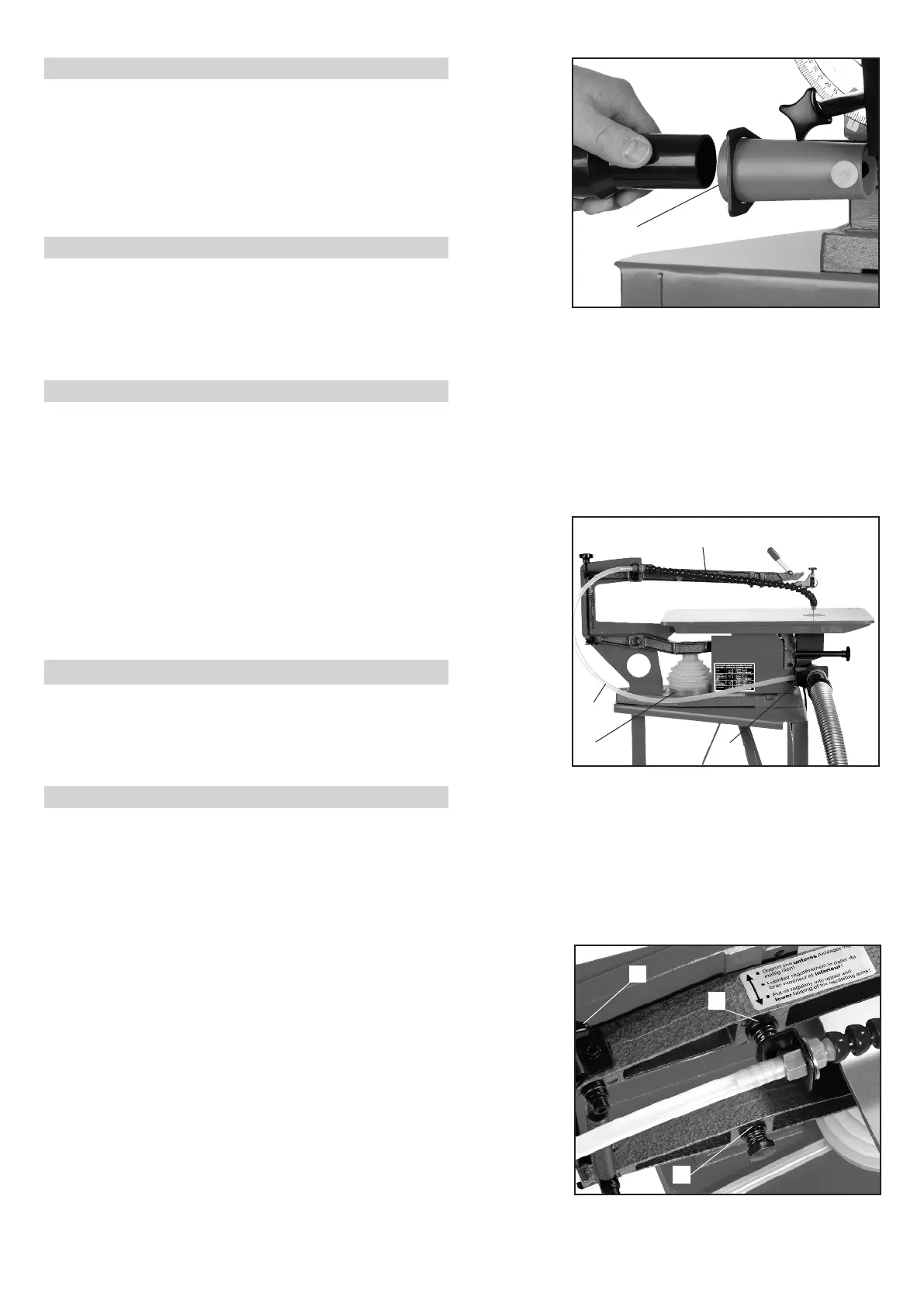

13.2 Adjust the upper extraction

⇒ Fig. 13-2

• Adjust the upper extraction hose (1) so that it lies on

the workpiece around 5 mm away from the saw blade.

If however you want to work without the extractor, the

cut line can be blown clear by pulling the hose (4) off

the connection piece (5) and inserting it in the pump

base (3).

When the dust extractor is not connected, the

machine may only be used for open air work. In

closed rooms the dust extractor must be connected

(see 13.0 Extraction connection).

14.0 Maintenance / Cleaning

The machine is low maintenance.

Only the upper and lower arm bearings need to be oiled

regularly (approx. every 10 operating hours) with a fine

non-resinous oil (e.g. sewing machine oil).

14.1 Maintenance – oil arm bearings

⇒ Fig. 14-1

• Remove any dust deposits at the lubrication points.

• Using a light oil, oil both arm bearings (1). Apply 3 to

4 drops of oil at the points marked with arrows

(between the swing arm and washer).

The clamping spindle (2) must not be oiled or

greased.

☞

☞

☞

☞

10

Fig. 13-1

Fig. 13-2

Fig. 14-1

1

1

3

1

1

2

4

5

Loading...

Loading...