15

441 01 2121 01

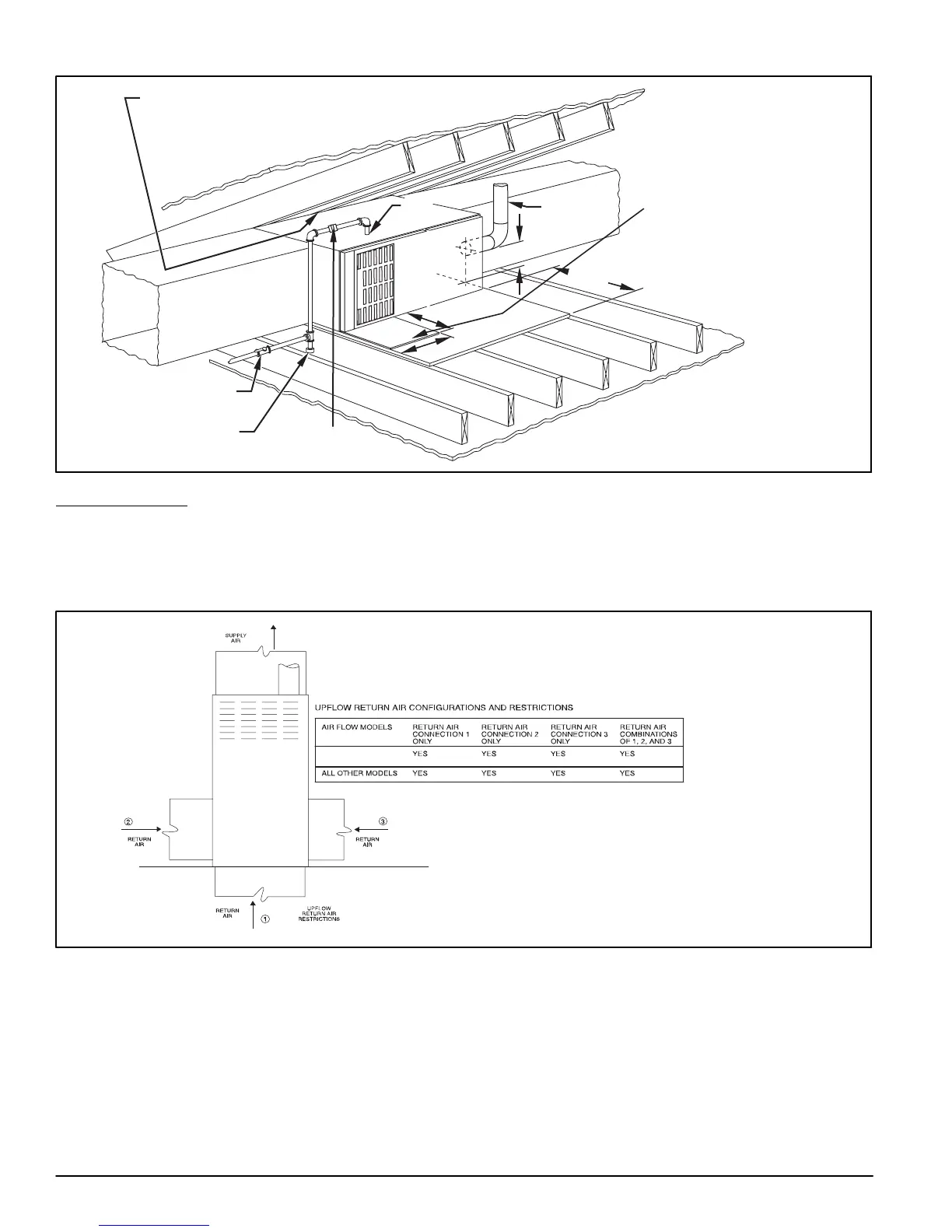

Figure 17 − Typical Attic Installation

30-IN . (762mm)

MIN WORK AREA

6 ″

M IN

*

TYPE-B

VENT

17

3

/

4

″

22

″

SHEET

MET AL

SEDIMENT

TRAP

EQUIPMENT MANU AL

SHUT -OFF GAS VA LV E

LINE CONT A CT ONL Y PERMISSIBLE BETWEEN

LINES FORMED BY INTERSECTIONS OF

THE T OP AND TW O SIDES OF THE FURNA CE

JA CKET AND BUILDING JOISTS ,

STUDS , OR FRAMING.

GAS

ENTR Y

17

3

/

4

″

(451mm)

OVERALL

4

3

/

4

″

(121mm)

UNDER DOOR

1 ″

(25mm)

UNDER FURNACE

EXTEND OUT 12 ″

(305mm)

FR OM FA CE OF DOOR

* WHEN USED W ITH

SINGLE W ALL VEN T

CONNECTIONS

UNION

(152mm)

(451mm)

(559mm)

A10164

Downflow Furnaces

Connect supply−air duct to supply−air outlet on furnace. Bend

flange inward past 90 with wide duct pliers (See Figure 14)

The supply−air duct must be connected to ONLY the furnace

supply outlet or air conditioning coil casing (when used).

When installed on combustible material, supply−air duct must

be connected to ONLY the accessory subbase or a factory

approved air conditioning coil casing. DO NOT cut main

furnace casing to attach supply side air duct, humidifier, or

other accessories. All accessories MUST be connected to

duct external to furnace casing.

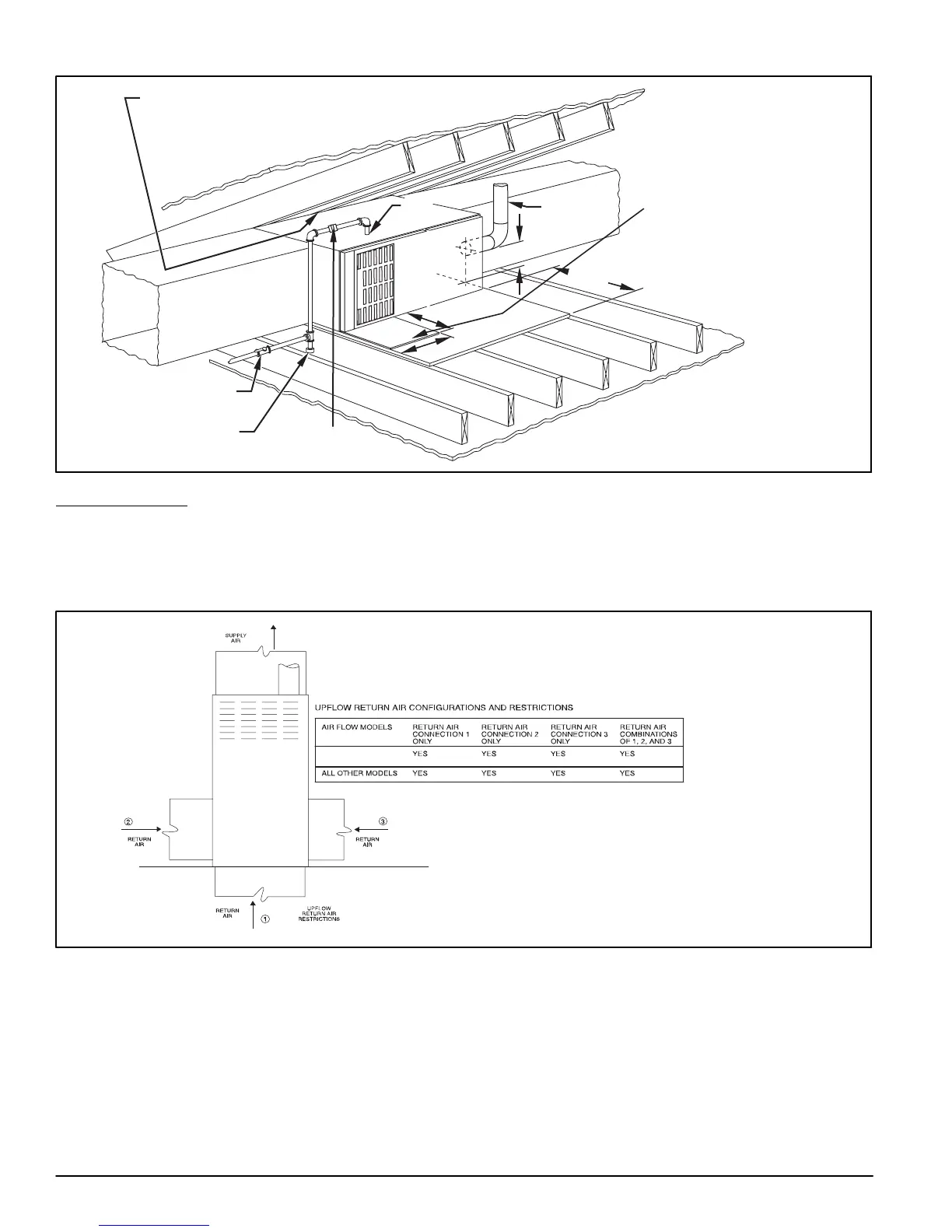

Figure 18 − Upflow Return Air Configurations and Restrictions

5 TONS AND

GREATER

*

*

2000 CFM AND GREATER AT .6 ESP HI COOLING SPEED

Loading...

Loading...