31

441 01 2121 01

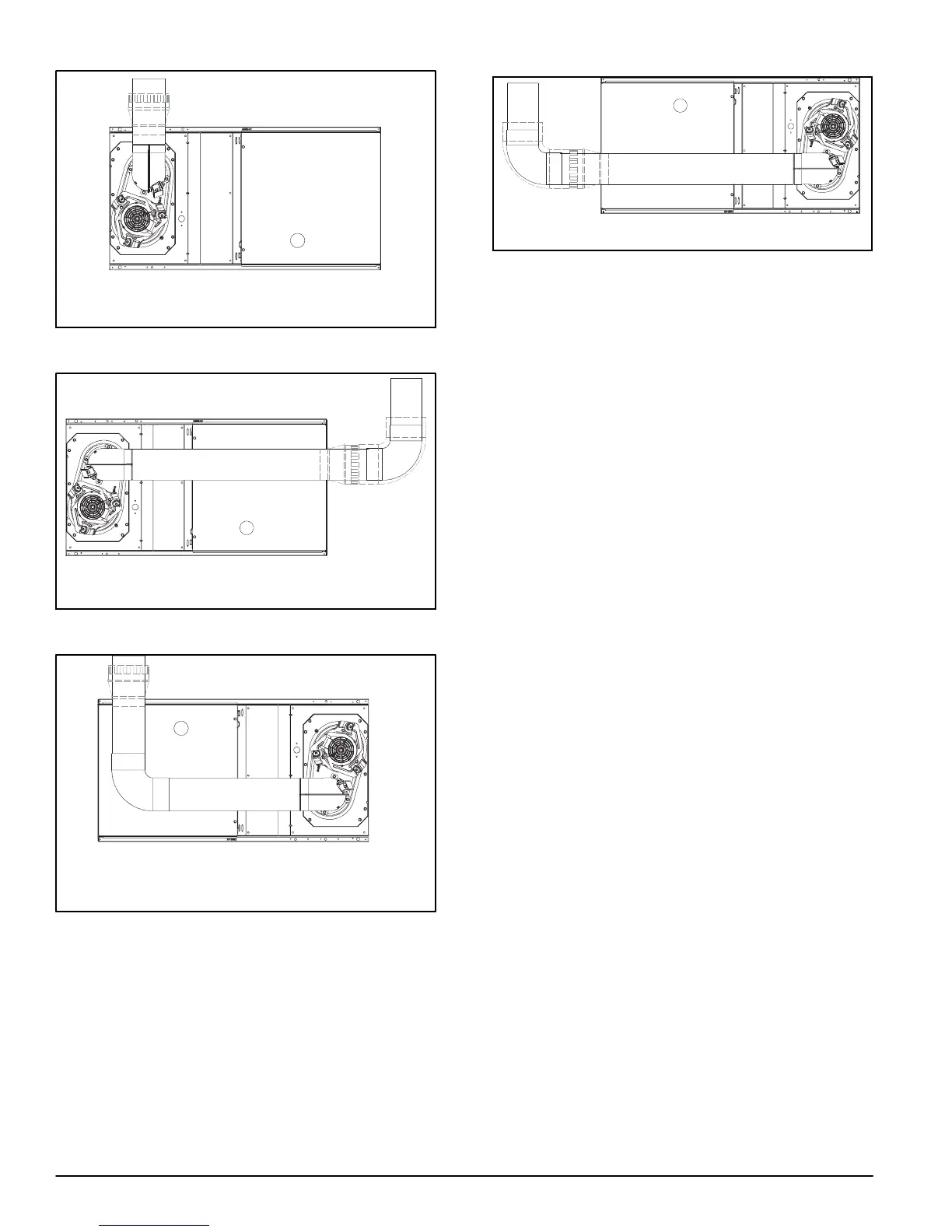

Figure 44 − Horizontal Left Application − Vent Elbow Up

SEE NOTES: 1,2,4,5,7,8,9 on the page

following these figures

A03215

Figure 45 − Horizontal Left Application − Vent Elbow

Right

SEE NOTES: 1,2,4,5,7,8,9 on the page

following these figures

A03216

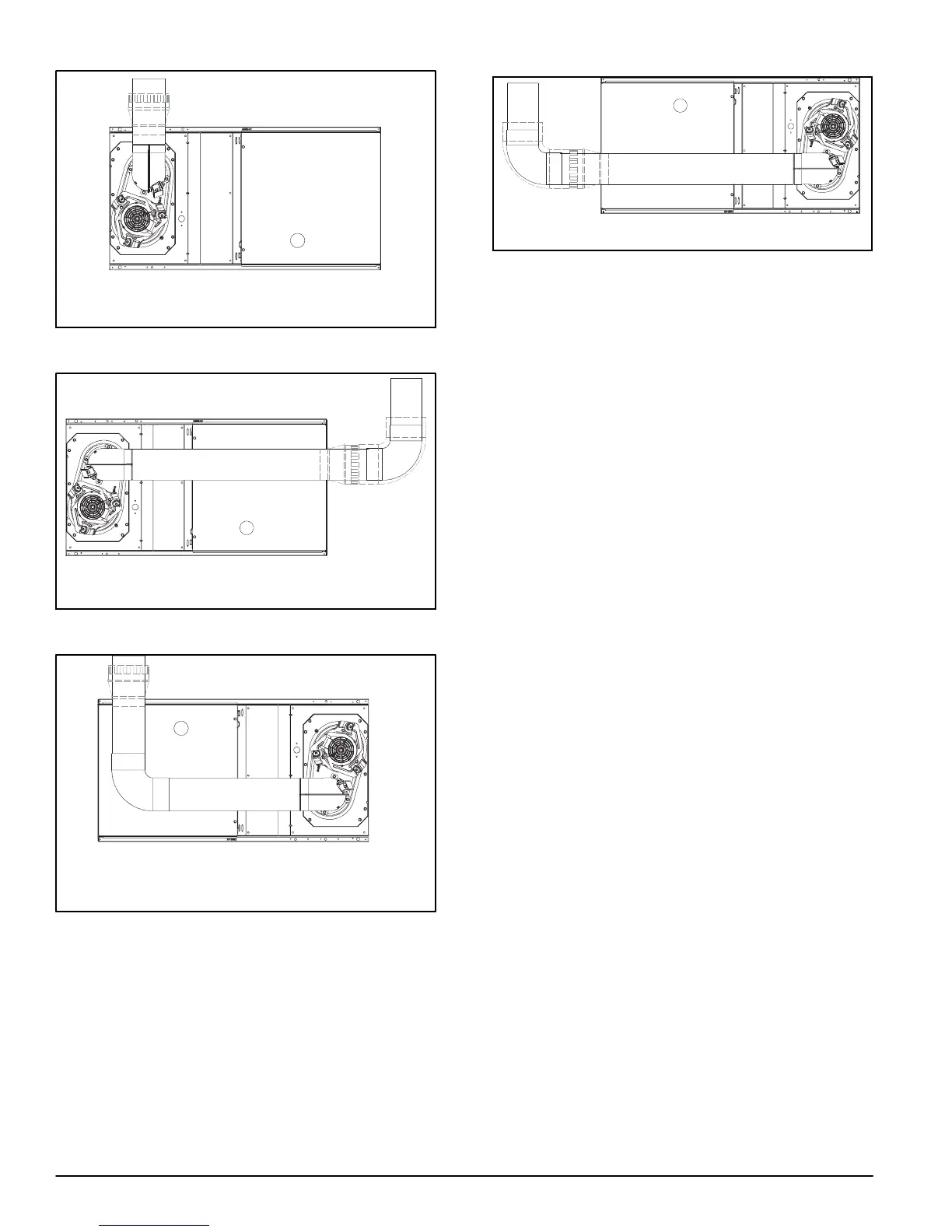

Figure 46 − Horizontal Right Application − Vent Elbow

Left then Up

SEE NOTES: 1,2,4,5,7,8,9 on the page

following these figures

A03219

Figure 47 − Horizontal Right Application−Vent Elbow Left

SEE NOTES: 1,2,4,5,7,8,9

A02068

VENTING NOTES FOR Figure 35 − Figure 47

1. For common vent, vent connector sizing and vent

material: United States−−use the NFGC.

2. Immediately increase to 5−in. (102 mm) or 6−in. (152

mm) vent connector outside furnace casing when 5−in.

(127 mm) vent connector is required, refer to Note 1

above.

3. Side outlet vent for upflow and downflow installations

must use Type B vent immediately after exiting the

furnace, expect when Downflow Vent Guard Kit is used

in the downflow position.

4. Type−B vent where required, refer to Note 1 above.

5. A 4−in.(102 mm) single−wall (26 ga. min.) vent must be

used inside furnace casing and when the

NAHB00301VC Downflow Vent Guard Kit is used

external to the furnace.

6. Accessory Downflow Vent Guard Kit is required in

downflow installations with lower vent configuration.

7. Chimney Adapter Kit may be required for exterior

masonry chimney applications. Refer to Chimney

Adapter Kit for sizing and complete application details.

8. Secure vent connector to furnace elbow with (2)

corrosion−resistant sheet metal screws, spaced

approximately 180 apart.

9. Secure all other single wall vent connector joints with

(3) corrosion resistant screws spaced approximately

120 apart. Secure Type−B vent connectors per vent

connector manufacturer’s recommendations.

NOTE: For the following applications, use the minimum vertical heights as specified below. For all other applications, follow

exclusively the National Fuel Gas Code.

FURNACE

ORIENTATION

VENT ORIENTATION FURNACE INPUT

(BTUH/HR)

MIN. VENT

DIAMETER

IN. (mm)*

MIN. VERTICAL VENT

HEIGHT

FT. (M)**

Downflow Vent elbow left, then up Figure 35 132,000/110,000 (3 ton only) 5 (127) 12 (3.6)

Horizontal Left Vent elbow right, then up Figure 38 132,000 5 (127) 7 (2.1)

Horizontal Left Vent Elbow up Figure 39 132,000 5 (127) 7 (2.1)

Downflow Vent elbow up then left Figure 33 110,000 (3 ton only) 5 (127) 10 (3.0)

Downflow Vent elbow up, then right Figure 36 110,000 (3 ton only) 5 (127) 10 (3.0)

NOTE: All vent configurations must also meet National Fuel Gas Code venting requirements NFGC.

*4−in. (102 mm) inside casing or vent guard

**Including 4 in. (102 mm) vent section(s)

Loading...

Loading...